Feeding system of ejecting machine

A technology of feeding system and injection machine, which is applied in the field of injection machine feeding system, can solve problems such as production stoppage, and achieve the effect of avoiding stoppage and improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

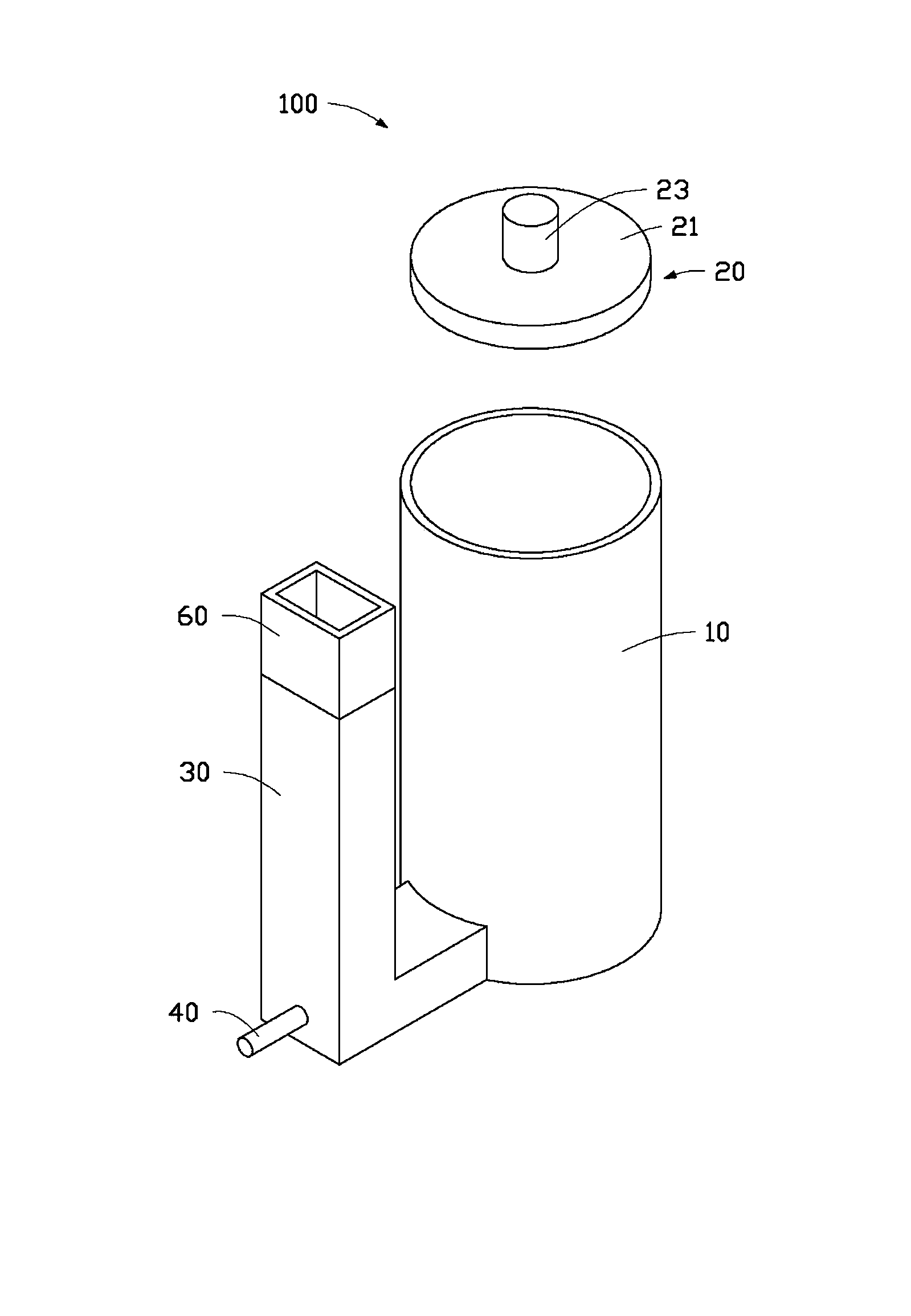

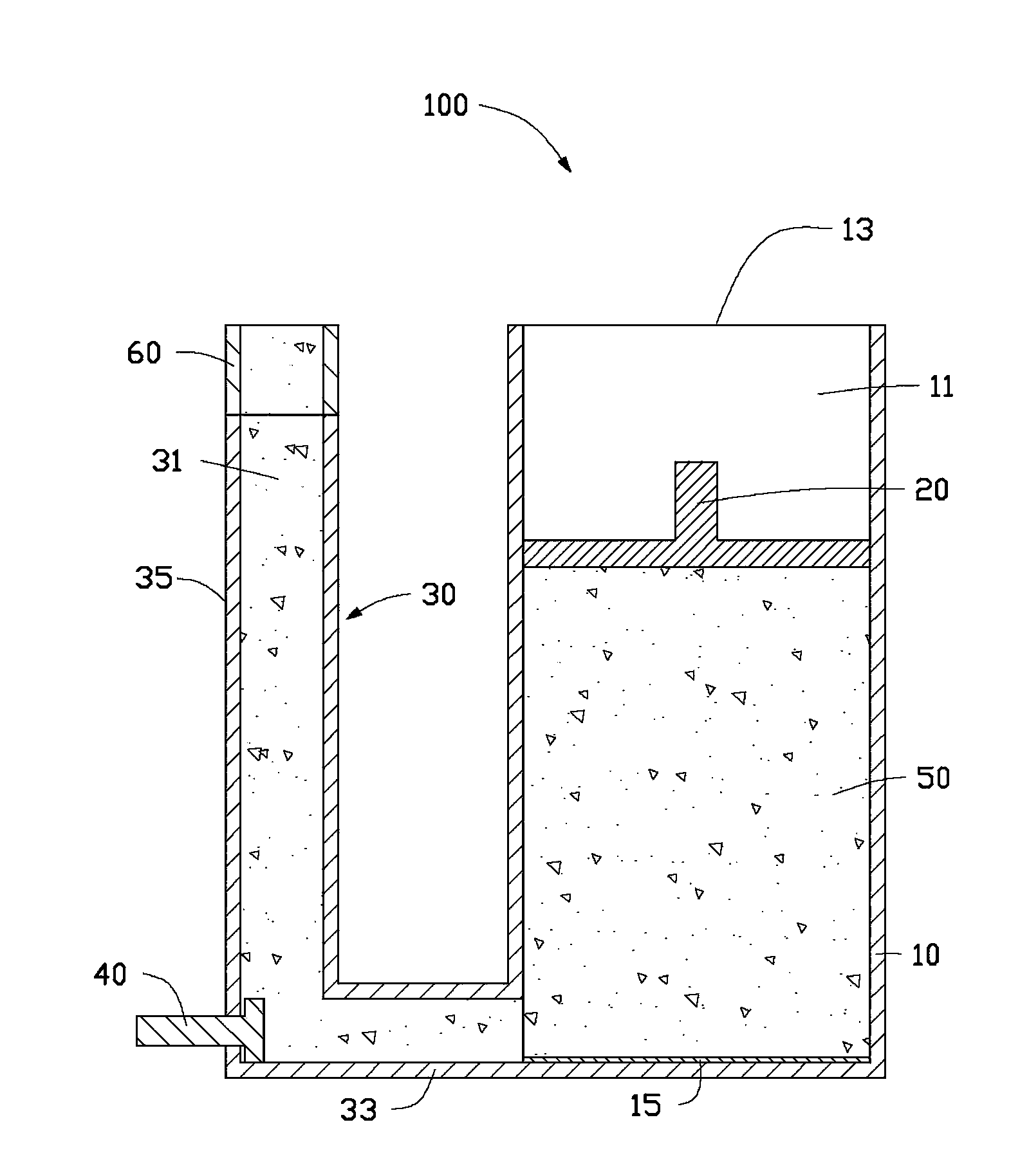

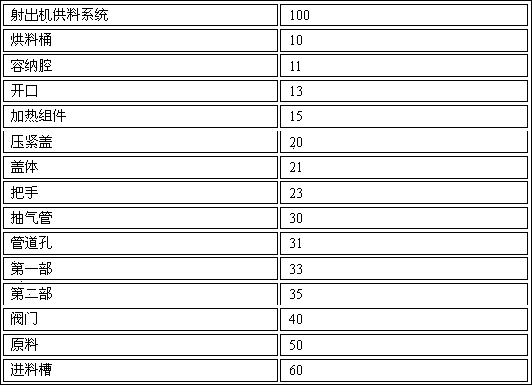

[0011] Please also refer to figure 1 and figure 2 , The injection machine feeding system 100 provided by the embodiment of the present invention includes a drying barrel 10 , a pressing cover 20 , an air extraction pipe 30 and a valve 40 . The drying material barrel 10 is connected with the air extraction pipe 30, and the raw material 50 is contained in the material drying barrel 10 and the air extraction pipe 30, and the air extraction pipe 30 is connected with the feed tank 60 of the injection machine. The feeding tank 60 is connected with an air extractor (not shown in the figure), and the air extractor draws air, thereby sucking the raw material 50 into the feeding tank 60 .

[0012] In this embodiment, the drying material barrel 10 is roughly cylindrical, and a cylindrical accommodation cavity 11 is formed inside the drying material barrel 10. The bottom end of the drying material barrel 10 is closed, and the accommodation cavity 11 is formed at the top of the drying ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com