Oxygen production system and method and oxygen production machine

The technology of an oxygen generator system and oxygen generator, applied in the field of oxygen generators, can solve the problems of low efficiency, too fast drop of oxygen concentration, unusable oxygen generator, etc., and achieve the effect of simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

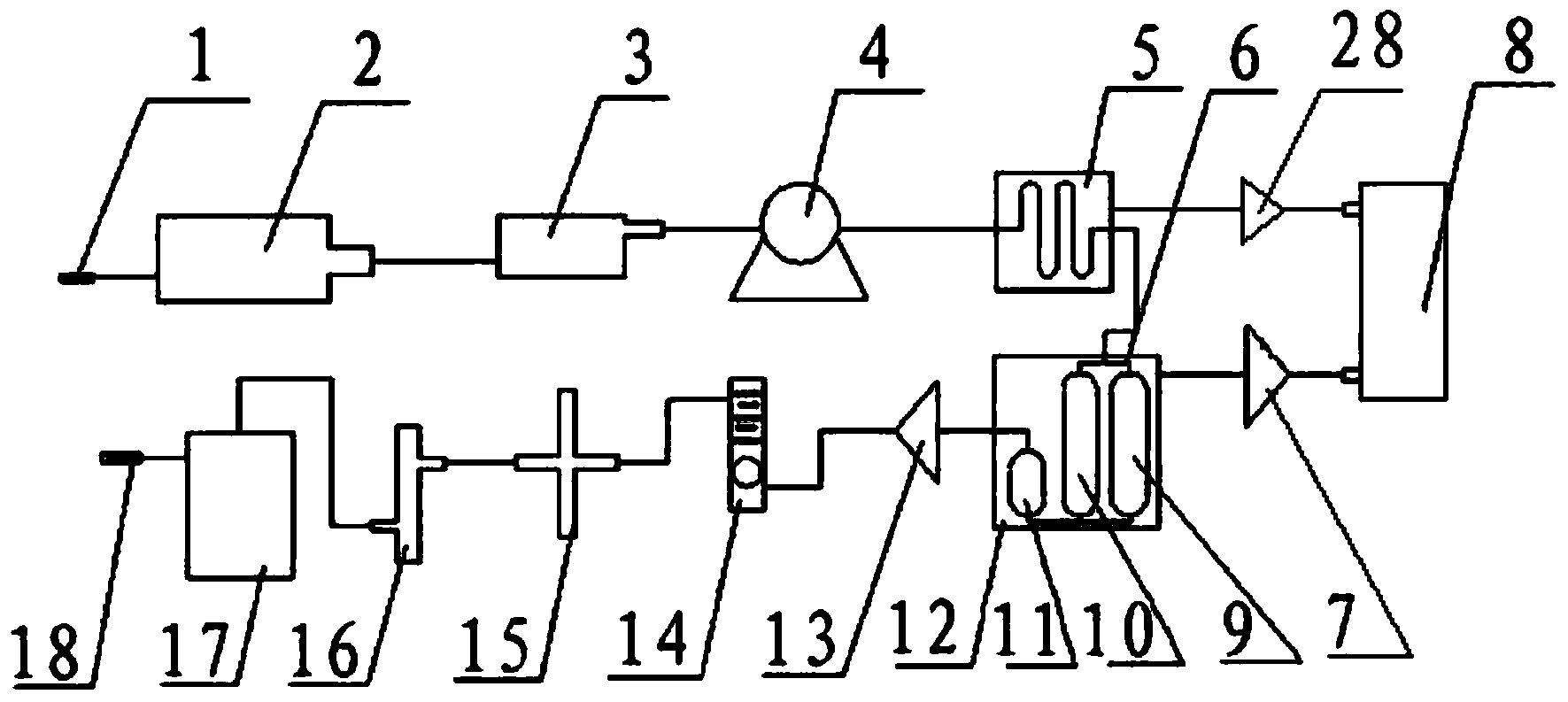

[0048] See figure 1As shown, an oxygen production system includes an air inlet 1, an air inlet filter 2, a compressor 4, an air inlet muffler 3, a heat dissipation and water removal device 5, an integrated adsorption tower 12, and an oxygen flow meter connected in sequence. 14. Bacteria filter 15, humidification bottle 17 and oxygen outlet 18, integrated adsorption tower 12 and heat dissipation dewatering device 5 are respectively connected to exhaust muffler 8, also includes processor (not shown), processor is connected with The intake filter 2, the intake muffler 3, the compressor 4, the heat dissipation and water removal device 5, the integrated adsorption tower 12, the exhaust muffler 8 and the bacteria filter 15 are electrically connected.

[0049] The processor controls the operation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com