A macroporous concrete containing low-quality recycled aggregate and its preparation method

A macroporous concrete and recycled aggregate technology, applied in ceramic products, other household appliances, sustainable waste disposal, etc. The effect of pH reduction and strong retardation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

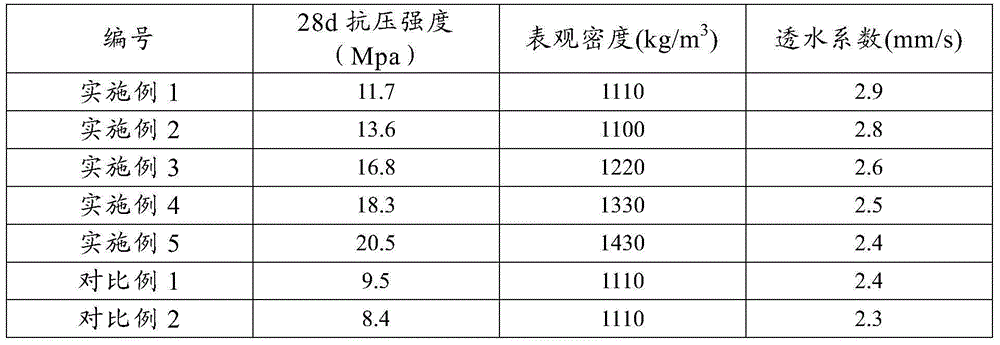

Examples

Embodiment 1

[0029] In this example, the raw material composition of macroporous concrete containing low-quality recycled aggregate includes, P.O42.5 cement 288kg / m 3 , water 89kg / m 3 , additional water 64kg / m 3 , low-quality recycled aggregate 656kg / m 3 , carboxymethyl starch 0.86kg / m 3 , Glucose 0.29kg / m 3 , wherein the particle size of the low-quality recycled aggregate is 5-16mm, and the bulk density is 700kg / m 3 .

Embodiment 2

[0031] In this example, the raw material composition of macroporous concrete containing low-quality recycled aggregate includes, P.O42.5 cement 310kg / m 3 , water 90kg / m 3 , additional water 66kg / m 3 , low-quality recycled aggregate 681kg / m 3 , starch sulfate 3.1kg / m 3 , sucrose 0.22kg / m 3 , wherein the particle size of the low-quality recycled aggregate is 5-16mm, and the bulk density is 700kg / m 3 .

Embodiment 3

[0033] In this example, the raw material composition of macroporous concrete containing low-quality recycled aggregate includes, P.O42.5 cement 340kg / m 3 , water 92kg / m 3 , additional water 69kg / m 3 , low-quality recycled aggregate 709kg / m 3 , a mixture of carboxymethyl starch and starch thioester (mass ratio 1:1) 2.72kg / m 3 , calcium sugar 1.36kg / m 3 , wherein the particle size of the low-quality recycled aggregate is 5-16mm, and the bulk density is 800kg / m3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com