Method for synthesizing superabsorbent resin with carboxymethyl cassava residue as raw material

The technology of superabsorbent resin and carboxymethyl wood is applied in the field of simple preparation, can solve the problems of low utilization, soil and groundwater pollution, environmental pollution and the like, and achieves the effect of cost saving and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

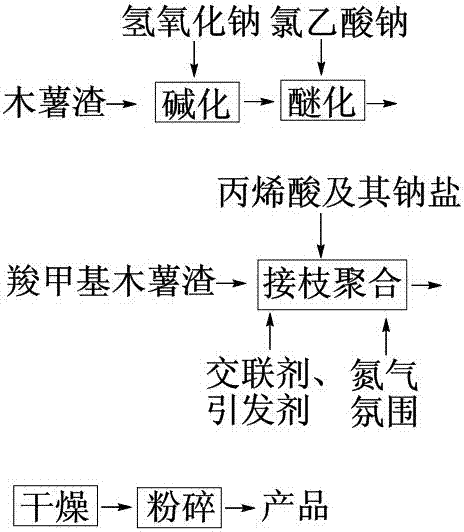

Method used

Image

Examples

Embodiment 1

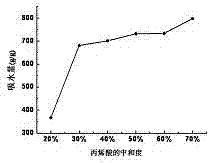

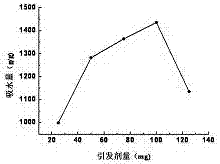

[0018] Example 1: Weigh 1.67g of sodium hydroxide, dissolve it in 27.5ml of deionized water, weigh 15g of acrylic acid, add the above-mentioned sodium hydroxide solution dropwise to acrylic acid under cooling in an ice-water bath and stir to neutralize it (the neutralization degree of acrylic acid 20%), weigh 2.5g carboxymethyl cassava residue and mix with 20ml deionized water, mix the neutralized acrylic acid and its sodium salt with carboxymethyl cassava residue solution, add 7.5ml concentration of 10mg / ml Potassium persulfate solution, 10ml of N,N'-methylenebisacrylamide solution with a concentration of 2mg / ml, nitrogen gas, stirring and heating slowly to gradually increase the temperature of the reaction system, when the temperature rises to 70-80°C Stop stirring when the temperature reaches 90°C and keep warm for 2 hours, take out the product, dry and pulverize to obtain superabsorbent resin, the water absorption of the superabsorbent resin prepared in this example is 367g...

Embodiment 2

[0019] Example 2: The synthesis conditions are the same as in Example 1, except that 2.50g of sodium hydroxide is weighed, dissolved in 27.5ml of deionized water, 15g of acrylic acid is weighed, and the above-mentioned sodium hydroxide solution is added dropwise to acrylic acid under cooling in an ice-water bath Stir in medium to neutralize (the degree of neutralization of acrylic acid is 30%), the water absorption of the superabsorbent resin prepared in this example in 2500 times deionized water is 681g / g.

Embodiment 3

[0020] Example 3: The synthesis conditions are the same as in Example 1, except that 3.33g of sodium hydroxide is weighed, dissolved in 27.5ml of deionized water, 15g of acrylic acid is weighed, and the above-mentioned sodium hydroxide solution is added dropwise to acrylic acid under cooling in an ice-water bath Stir in medium to neutralize (the degree of neutralization of acrylic acid is 40%), the water absorption of the superabsorbent resin prepared in this example in 2500 times deionized water is 701g / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com