Manufacturing method of polyacetal copolymer

A technology of polyacetal copolymer and manufacturing method, which is applied in the field of polyacetal copolymer manufacture, and can solve the problems of not fully solving the problem of tar-like precipitates such as the generation of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

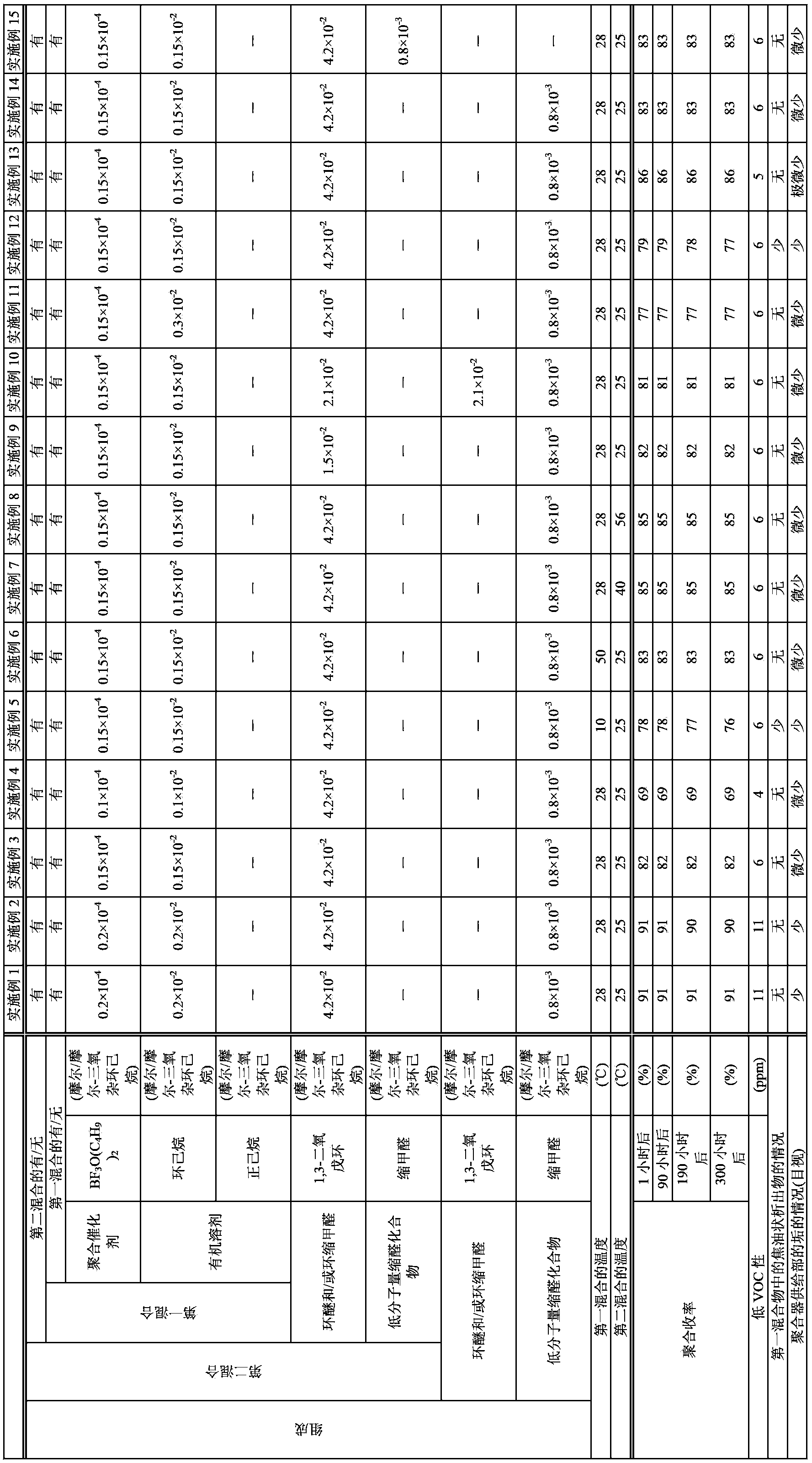

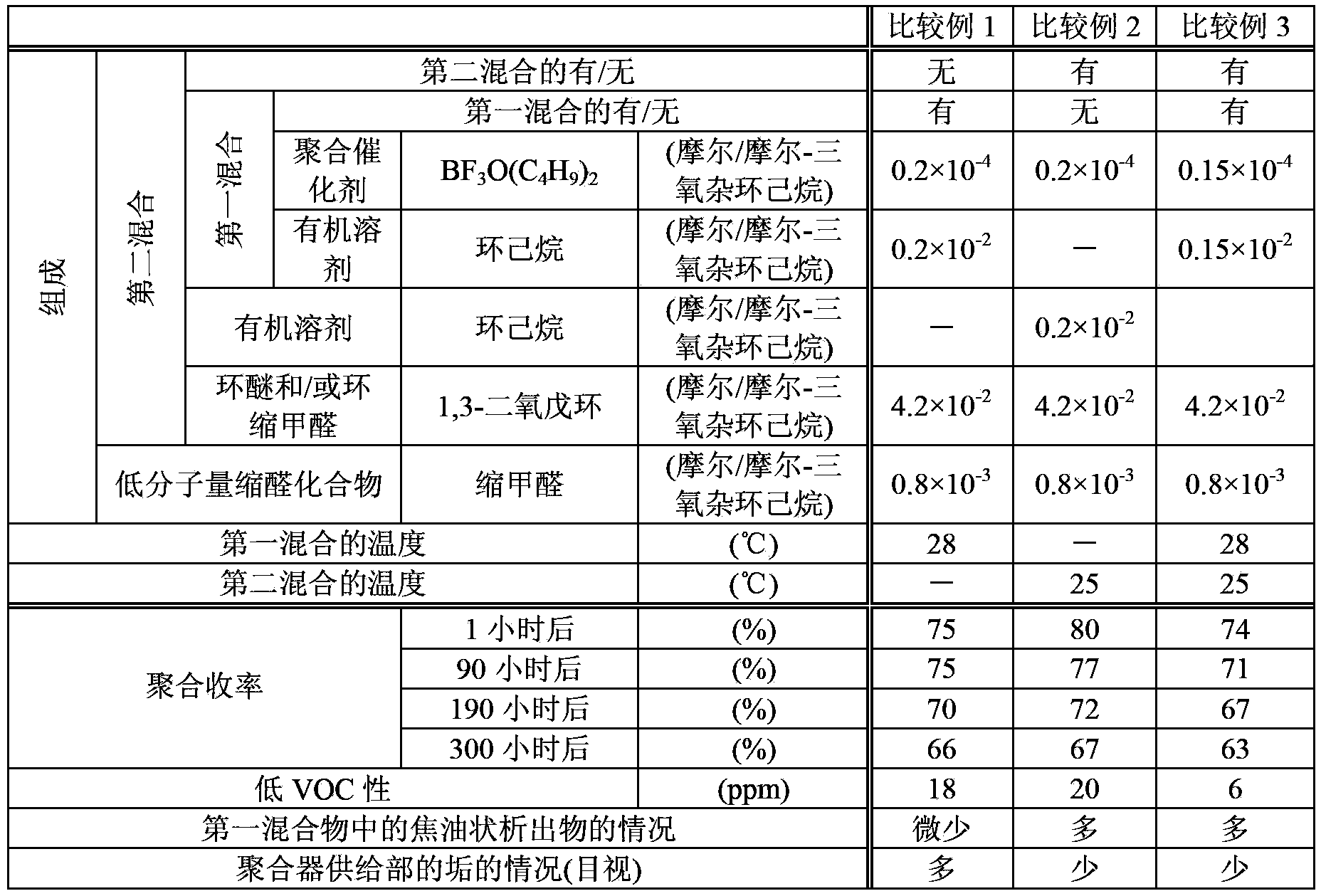

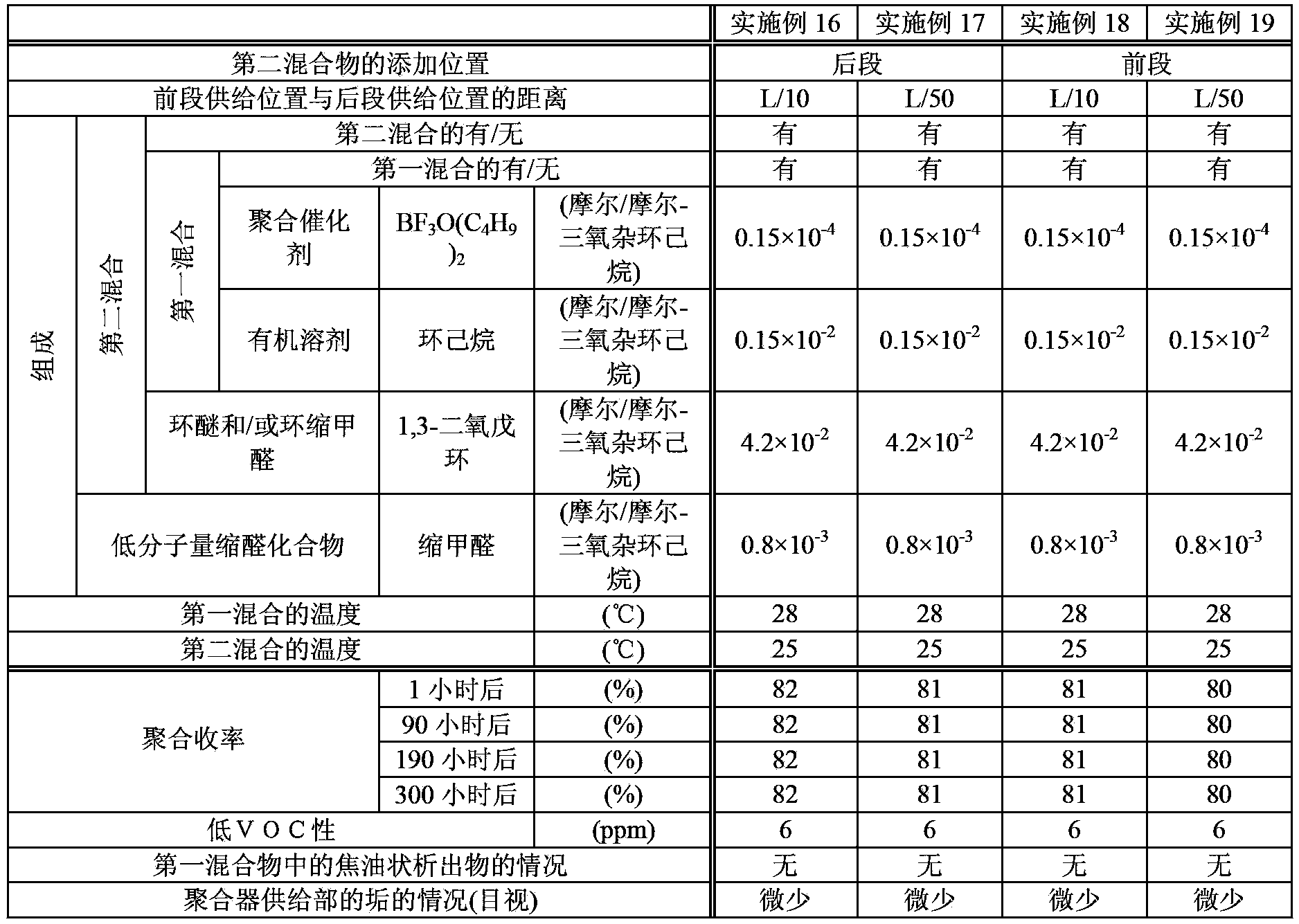

Examples

Embodiment 1

[0093] 63 g of boron trifluoride n-butyl ether complex as a polymerization catalyst and 2275 g of cyclohexane as an organic solvent were supplied to a preparation container with a circulation function by using a pump, and mixed for 20 minutes at a temperature of 28° C. (first mixing ).

[0094] Next, at a temperature of 25°C and a mixing time of 10 minutes, mix 6.68 g / hour of the above-mentioned first mixture with 120.9 g / hour of 1,3-dioxolane as a cyclic ether and / or cyclic formal Mixing takes place continuously in the pipeline (secondary mixing).

[0095] The above-mentioned second mixing uses a static mixer.

[0096] The concentration of the polymerization catalyst in the above-mentioned second mixture is 1.41×10 -1 quality%.

[0097] A jacketed twin-shaft paddle-type continuous polymerization reactor (manufactured by Kurimoto Iron Works, 5.08 cm in diameter, L / D=14.8) capable of circulating the heat medium was adjusted to 80° C., and 127.58 g / hour The above-mentioned s...

Embodiment 2

[0101] The conditions were the same as in Example 1, but the polymerization conditions were changed halfway.

[0102] After 100 hours of polymerization under the same conditions as in Example 1, the conditions were changed to 72.9 g / hour of the above-mentioned second mixture, 2000 g / hour of trioxane, and 1.4 g / hour of formal. After 100 hours of polymerization, the conditions were changed to 182.26 g / hour of the above-mentioned second mixture, 5000 g / hour of trioxane, and 3.4 g / hour of formal, and polymerization was carried out for 100 hours.

[0103] The results are shown in Table 1.

Embodiment 3~4

[0105] The amounts of the polymerization catalyst and the organic solvent were changed to those shown in Table 1. Other conditions were the same as in Example 1 to obtain a polyacetal copolymer. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com