Schreyerite furnace protection method and device

A technology of vanadium-titanium ore and blast furnace, which is applied to the online repair and maintenance of the furnace bottom lining. In the hearth field below the tuyere of the ironmaking blast furnace, it can solve the problems that cannot effectively solve the impact of the hearth, lining repair, and feeding. and different methods to achieve the effect of convenient movement, extended service life and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

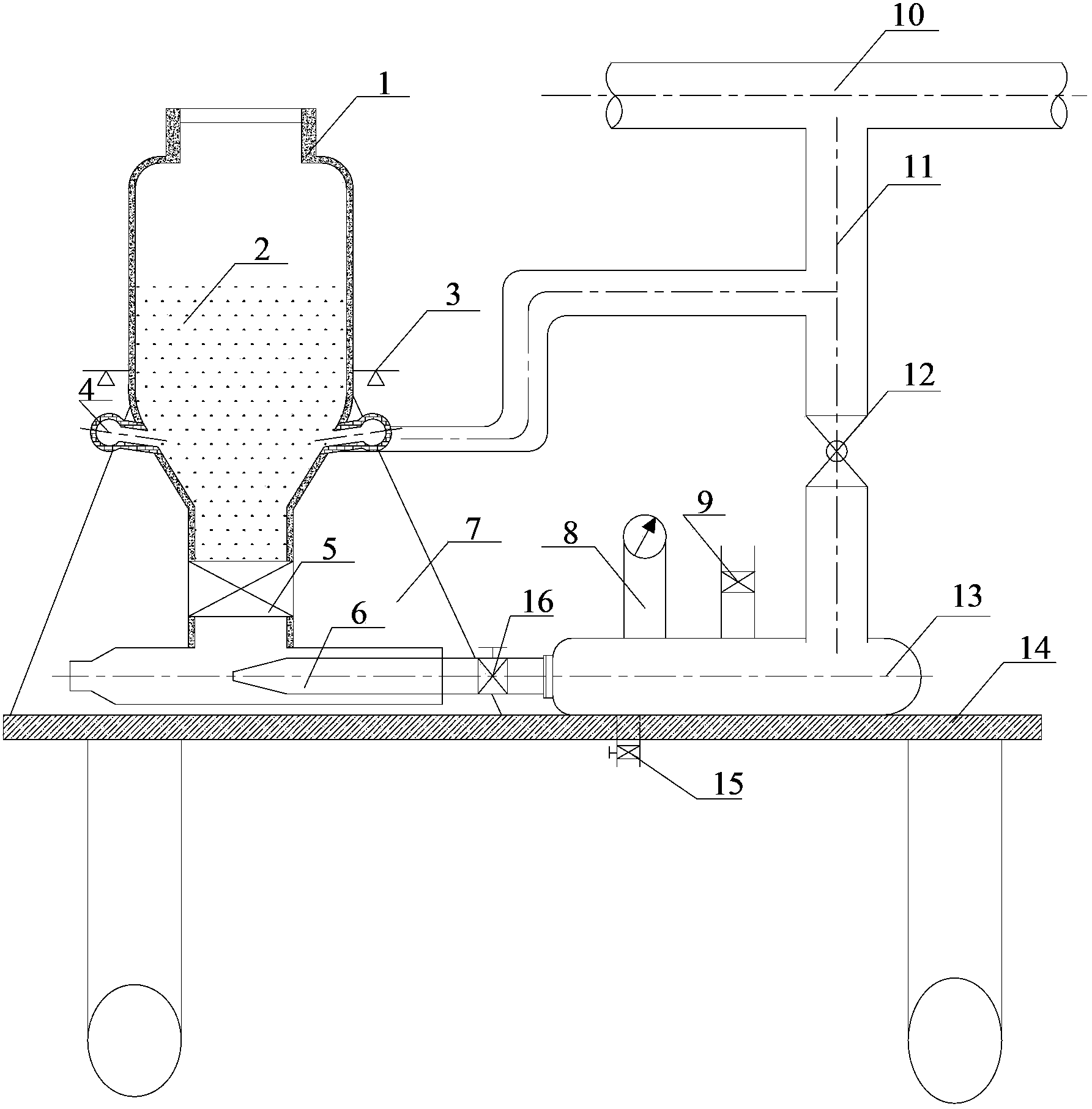

[0028] With a volume of 3200m 3 Take the blast furnace as an example. When the blast furnace is running forward, the amount of pig iron produced by the iron gauge is 625t every two hours. The amount of vanadium-titanium ore to protect the furnace is 5-20 kg / t pig iron, of which 6-10 kg / t pig iron is used in the early stage of blast furnace production, and 12-16 kg / t pig iron is used to inject vanadium-titanium ore in the later stage. 20kg vanadium-titanium ore / t pig iron, 6-10 kg vanadium-titanium ore / t pig iron in the early stage, 12-16 kg vanadium-titanium ore / t pig iron in the later stage, the N 2 The pressure is higher than the air supply pressure, that is, 0.8~1.2MPa.

[0029] In the early stage of blast furnace production, based on the injection amount of 8 kg of pig iron vanadium-titanium ore, if the injection amount of vanadium-titanium ore is 5 tons in two hours, the injection amount is 41.7 kg / min, and the required N 2 The pressure is 0.9 MPa.

[0030] All devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com