High-intensity creep-resistant and low-copper alloy material and application thereof

A copper alloy, creep-resistant technology, applied in metal/alloy conductors, contact parts, etc., can solve the problems of less than 25%, high level, shortage of copper resources, etc., and achieve good plasticity, creep resistance improvement, and excellent creep resistance. The effect of changing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] 25 example alloys and 2 comparative alloys were selected (comparative example 1 was alloyed according to ZL201010246298.6, and comparative example 2 was alloyed according to ZL201010245802.0), and the same process was used to process them into Ф11.3 Finished products: cast slabs are made by continuous casting or die casting, hot extruded into rods at a temperature of 180°C-380°C, and finally finished by cold drawing to make a finished product of Ф11.3.

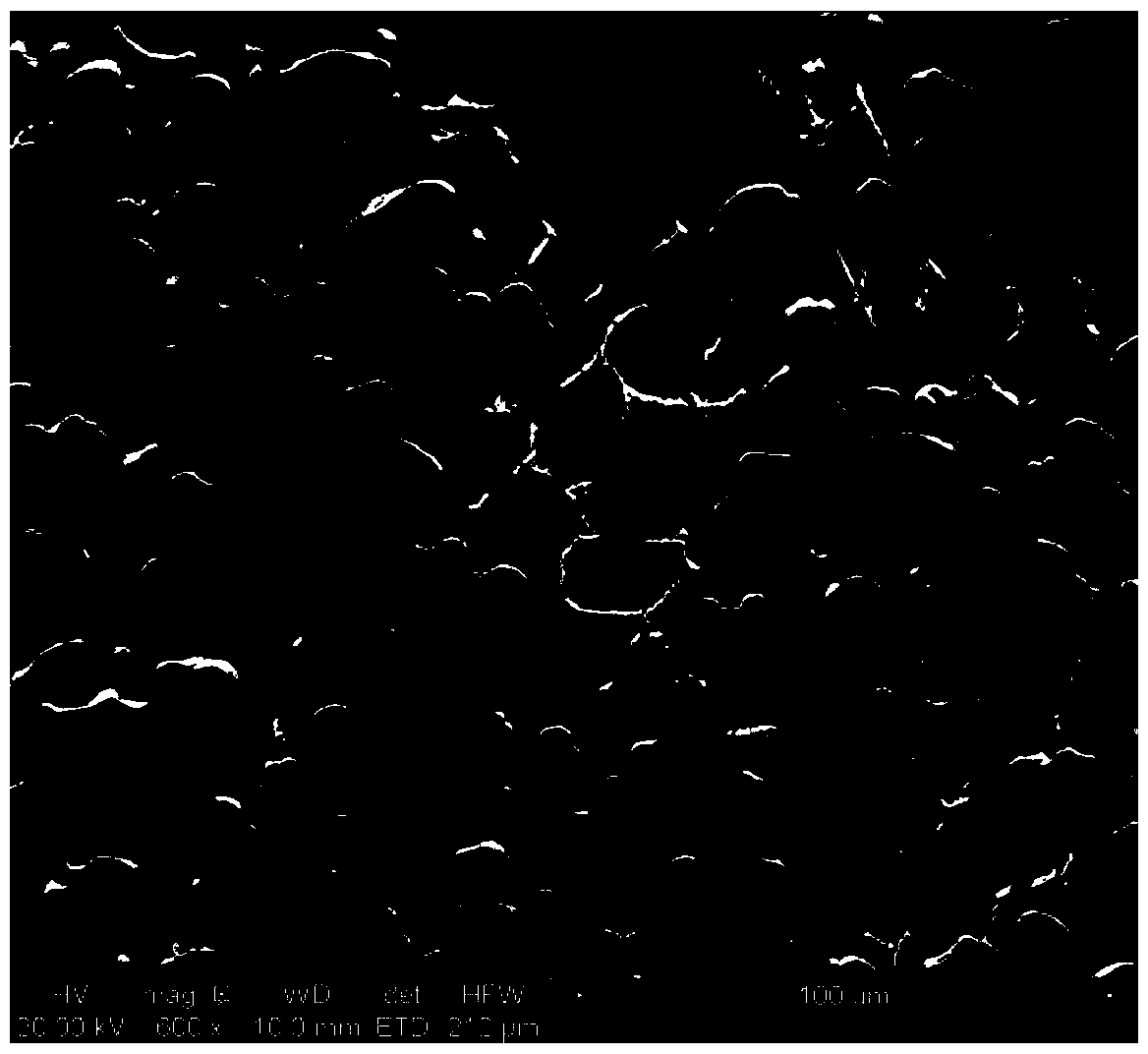

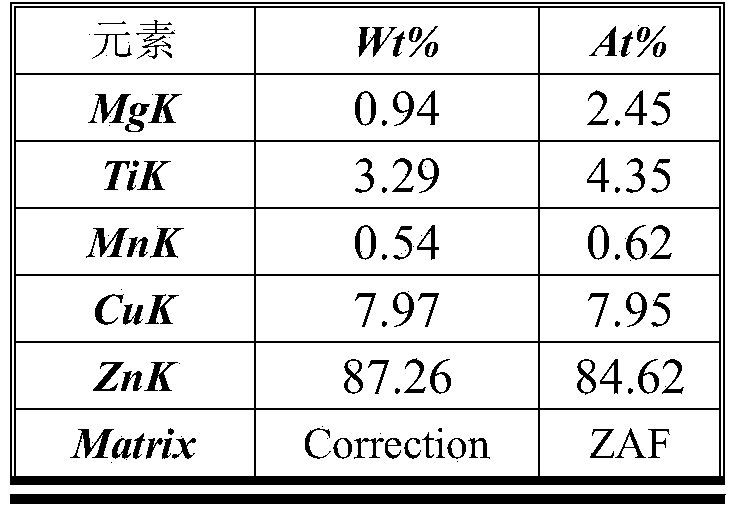

[0026] The SEM picture of the typical as-cast state structure of the low copper alloy material of the present invention is as figure 1 (×600) and figure 2 As shown in (×2500), the as-cast structure contains matrix Zn, equiaxed chrysanthemum CuZn 5 Zn-Cu-Ti-Mg-Mn compound of phase and ribbon network, the energy spectrum analysis result of Zn-Cu-Ti-Mg-Mn compound is as follows image ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com