Silver electrolytic tank

A silver electrolytic cell and front cell technology, which is applied in the field of silver electrolytic refining, can solve the problems of incorrect electrode placement and uneven current density distribution, and achieve the effects of improving production efficiency, improving current utilization, and ensuring strict equidistant spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further disclose the technical solution of the present invention, the implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

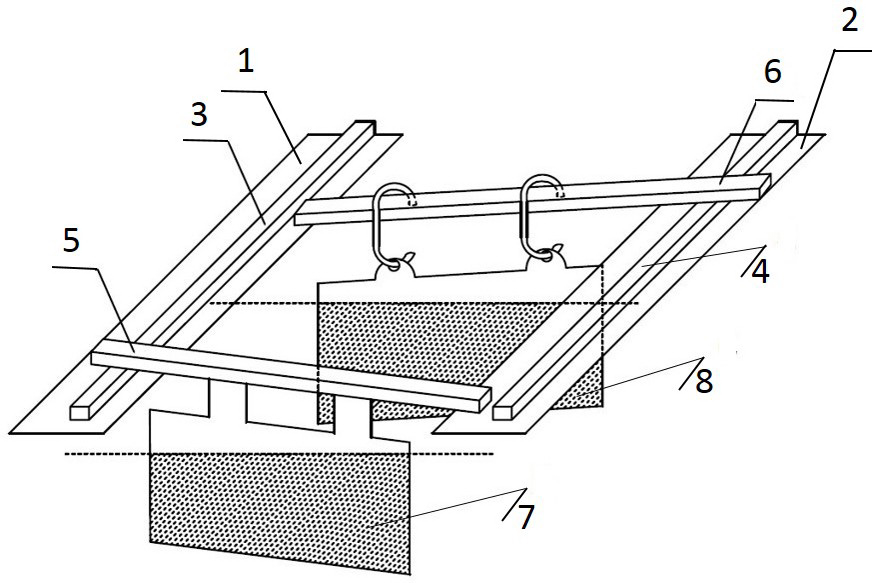

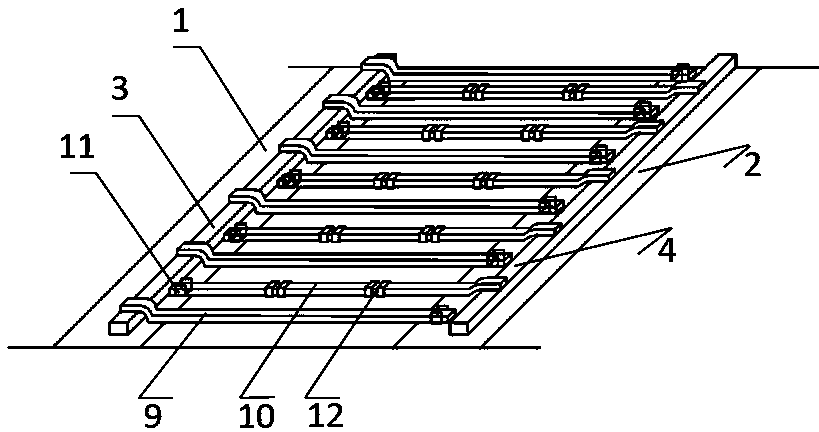

[0029] Such as figure 2 and image 3 Shown, a kind of silver electrolytic cell comprises several silver electrolytic cell bodies connected in series, and described silver electrolytic cell body comprises front cell edge 1, rear cell edge 2, the first cell that is placed on front cell edge 1 and conducts electricity in series Row 3, the second inter-slot series conductive bar 4 placed on the rear slot edge 2, some negative electrode conductive rods 9 for connecting the first inter-slot series conductive bar 3 and the cathode plate, several for connecting the second inter-slot series Conductive row 4 and the positive electrode conductive rod 10 of the anode plate. The front groove edge 1 is parallel to the rear groove edge 2.

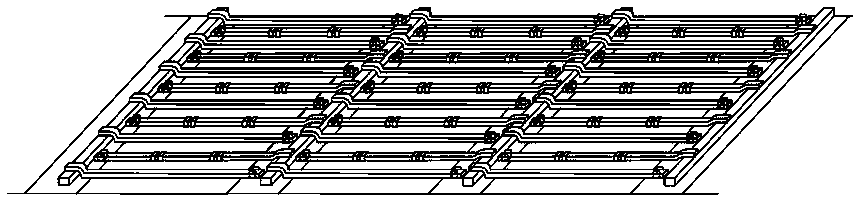

[0030] Such as Figure 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com