Dampproof sound isolation elastic plastic floor and preparing method of dampproof sound isolation elastic plastic floor

A technology of elastic plastics and floors, applied in chemical instruments and methods, insulation layers, lamination devices, etc., can solve the problems of laminated floors and sound-absorbing materials that cannot last for a long time, and achieve good laying effect, convenient laying, and good dimensional stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

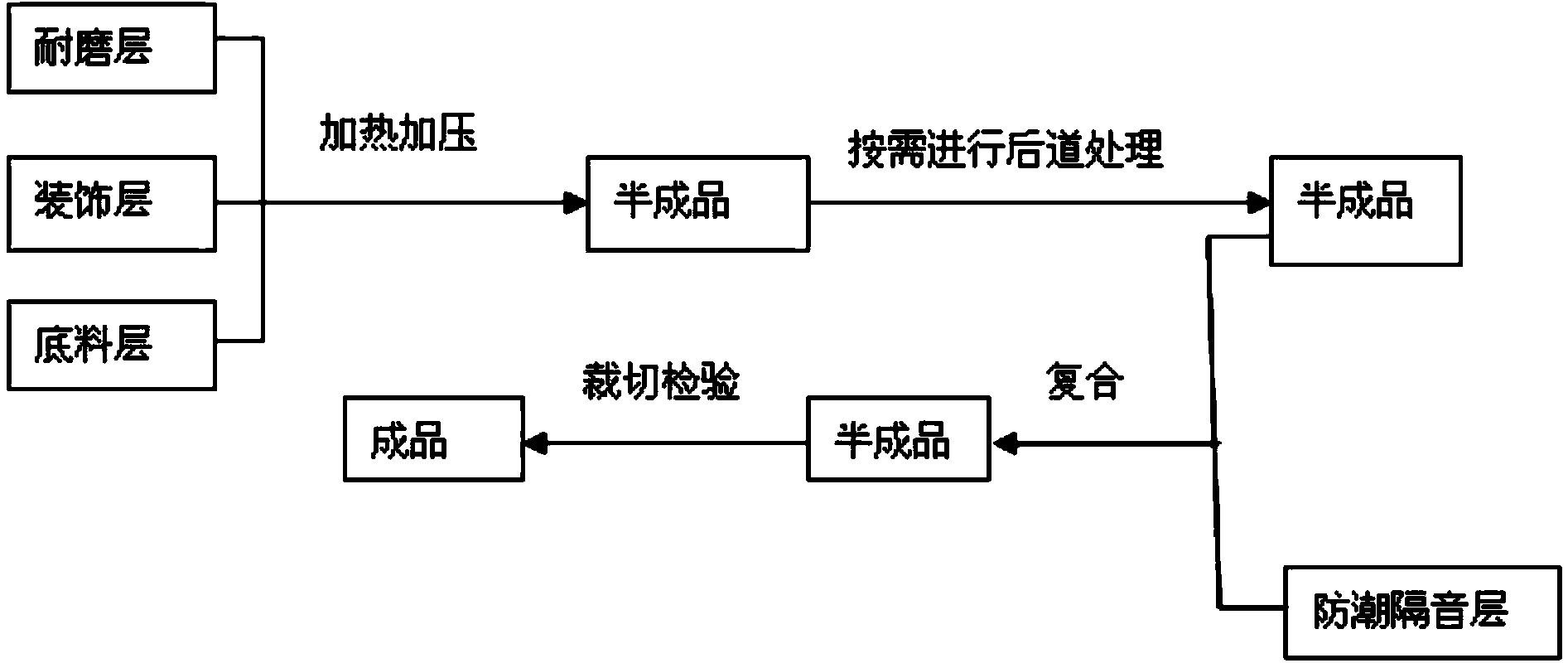

[0057] Preparation of moisture-proof and sound-insulating elastic plastic floor

[0058] Press the wear-resistant layer, decorative layer and first primer layer at 110°C and 90kg pressure for 20 minutes to prepare a semi-finished product, cool the obtained semi-finished product at 25°C and 50kg pressure for 20 minutes, and then compound it with the self-adhesive moisture-proof and sound-insulating layer , the semi-finished product obtained by compounding is subjected to cutting inspection to obtain the moisture-proof and sound-insulating elastic plastic floor.

[0059] Sound insulation performance test of moisture-proof and sound-insulating elastic plastic floor

[0060] Divide the plastic floor into a comparison group and an experiment group. The comparison group is an ordinary elastic plastic floor on the market, and the experiment group is the moisture-proof and sound-insulating elastic plastic floor provided by this application. The standard ASTM E2179-09 is used for t...

Embodiment 2

[0074] Preparation of moisture-proof and sound-insulating elastic plastic floor

[0075] Press the wear-resistant layer, decorative layer and first primer layer at 150°C and 40kg pressure for 40 minutes to prepare a semi-finished product, cool the obtained semi-finished product at 15°C and 90kg pressure for 30 minutes, and then put the prepared semi-finished first primer One side of the layer is coated with glue, and compounded with the moisture-proof and sound-insulating layer, and the obtained semi-finished product is cut and inspected to obtain the above-mentioned moisture-proof and sound-insulating elastic plastic floor.

Embodiment 3

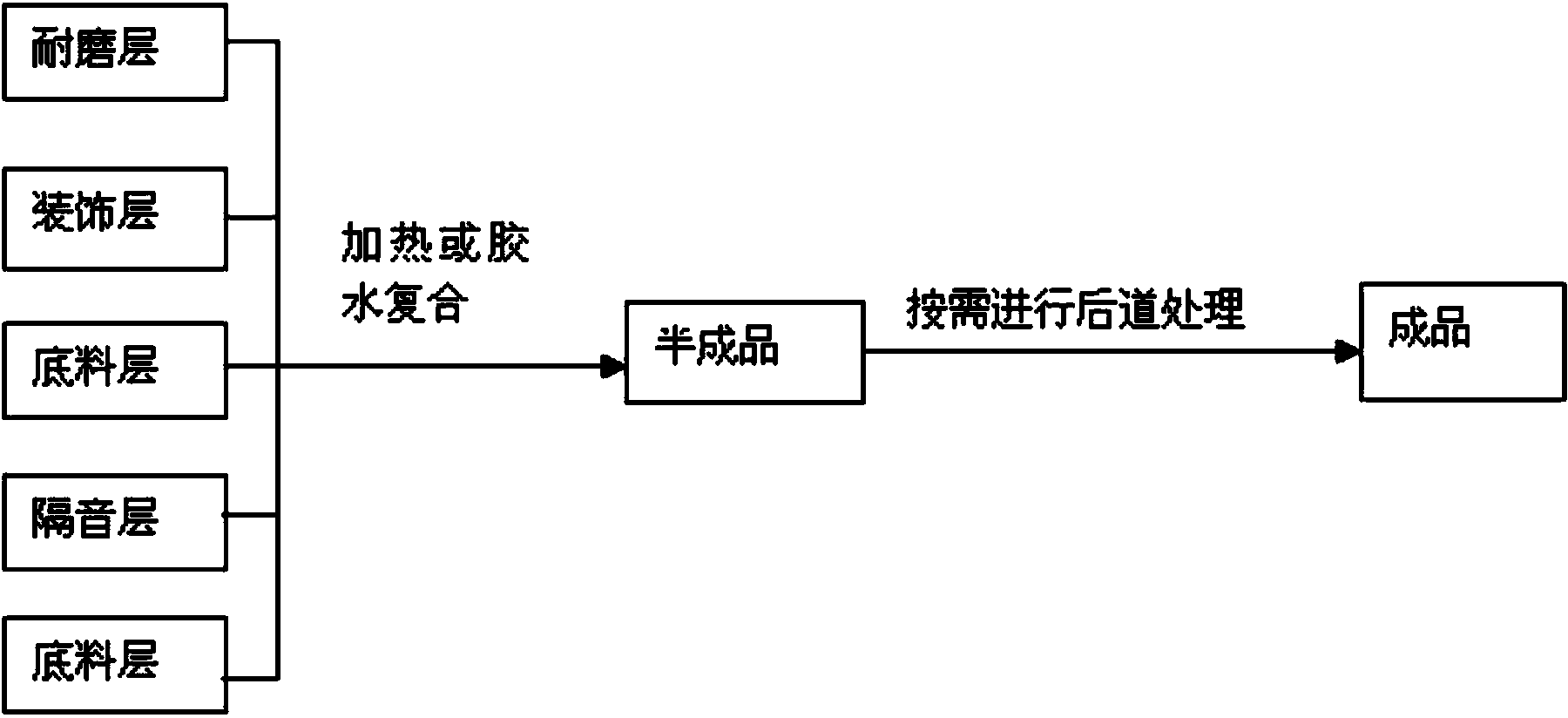

[0077] Preparation of moisture-proof and sound-insulating elastic plastic floor

[0078] Press the wear-resistant layer, decorative layer, first primer layer, sound insulation layer and second primer layer at 160°C for 80 minutes to prepare a semi-finished product, cool the obtained semi-finished product at 20°C for 20 minutes, and punch the cooled semi-finished product The moisture-proof and sound-insulating elastic plastic floor was obtained through inspection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com