Debuggable movable hydraulic oil source

A technology of hydraulic oil source and hydraulic oil, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of low precision and non-adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

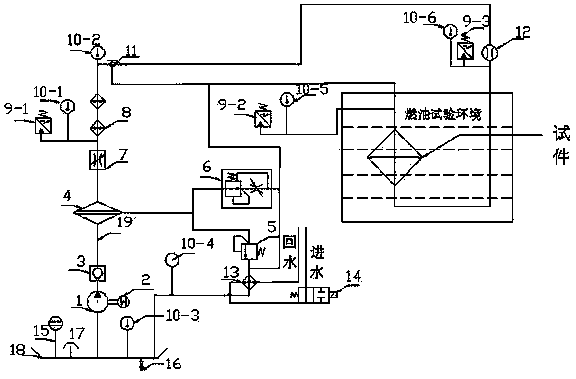

[0010] An adjustable mobile hydraulic oil source, including: hydraulic pump 1, motor 2, check valve 3, oil filter 4, overflow valve 5, speed control valve 6, throttle valve 7, liquid level gauge 15, stop valve 16 , three-way ball valve 11, air filter 17, oil pipe 19 and fuel tank 18, also includes: electric heater A8-1, electric heater B8-2, pressure sensor A9-1, pressure sensor B9-2, pressure sensor C9-3 , temperature sensor A10-1, temperature sensor B10-2, temperature sensor C10-3, temperature sensor D10-4, temperature sensor E10-5, temperature sensor F10-6, flow sensor 12, heat exchanger 13 and proportional water valve 14 . The bottom of the fuel tank is connected to the shut-off valve 16 through a pipe joint, the air filter 17 is installed on the top of the fuel tank through bolts, the fuel tank 18 is connected to the oil suction port of the hydraulic pump 1 through a hard pipe, and the input shaft of the hydraulic pump 1 is connected to the motor 2 through a coupling And...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com