Photoelectric comprehensive cable compact in structure and manufacturing method thereof

An optoelectronic integrated cable with a compact structure, which is used in the manufacture of cables/conductors, insulated cables, communication cables, etc. It can solve the problems of impact, poor pressure performance, high cost, and large structure of optical cables. /Strong impact/bending performance, low cost and high production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

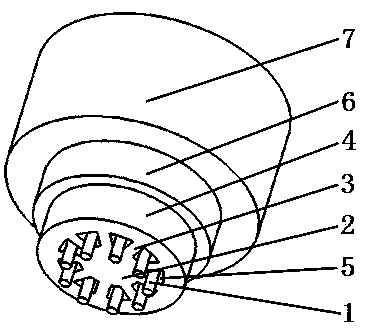

[0043] please see figure 1 and figure 2 , a compact photoelectric integrated cable, which includes nine optical fibers 1, strengthening elements 6, and outer sheath 7, is characterized in that it also includes a central support body 2, a peripheral support body 4, and connects the central support body to the peripheral The nine connecting strips 3 connected by the supporting body, the connecting strip, the outer space of the central supporting body, and the inner space of the peripheral supporting body form nine fiber-containing cavities 5, the optical fibers are located in the fiber-containing cavity and each fiber-containing cavity is radially The width can only accommodate 1 optical fiber, the outer sheath is located outside the outer support body, and the strengthening element is located between the outer support body and the outer sheath.

Embodiment 2

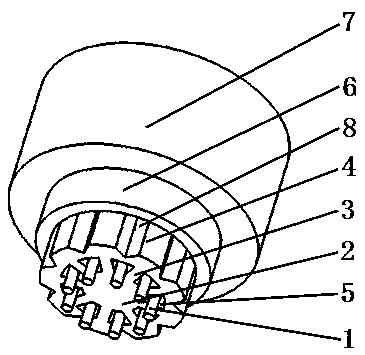

[0045] please see image 3 and Figure 4 , a compact photoelectric integrated cable, which includes nine optical fibers 1, strengthening elements 6, and outer sheath 7, is characterized in that it also includes a central support body 2, a peripheral support body 4, and connects the central support body to the peripheral The nine connecting strips 3 connected by the supporting body, the connecting strip, the outer space of the central supporting body, and the inner space of the peripheral supporting body form nine fiber-containing cavities 5, the optical fibers are located in the fiber-containing cavity and each fiber-containing cavity is radially The width can only accommodate 1 optical fiber, the outer sheath is located outside the peripheral support body, the strengthening element is located in the outer sheath, and there are 2 strengthening elements, which are symmetrically distributed in the outer sheath.

Embodiment 3

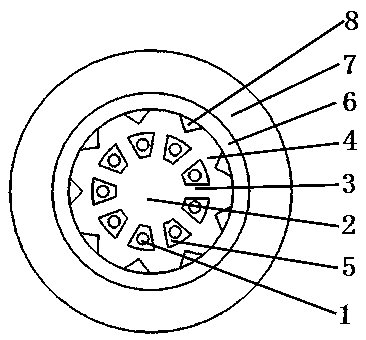

[0047] please see Figure 5 and Figure 6 , a compact photoelectric integrated cable, which includes nine optical fibers 1, strengthening elements 6, and outer sheath 7, is characterized in that it also includes a central support body 2, a peripheral support body 4, and connects the central support body to the peripheral The nine connecting strips 3 connected by the supporting body, the connecting strip, the outer space of the central supporting body, and the inner space of the peripheral supporting body form nine fiber-containing cavities 5, the optical fibers are located in the fiber-containing cavity and each fiber-containing cavity is radially The width can only accommodate 1 optical fiber, the outer sheath is located outside the peripheral support body, the strengthening element is located in the outer sheath, and there are 4 strengthening elements, which are symmetrically distributed in the outer sheath.

[0048] Of course, the reinforcing elements in the implementation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com