Method and device for stripping casing pipes of aluminum electrolytic capacitors

A technology of aluminum electrolytic capacitors and stripping devices, which is applied in the direction of capacitor casing/packaging, capacitors, capacitor manufacturing, etc., can solve the problems of reducing the internal quality of capacitors, high labor intensity of operators, and high costs, so as to improve the economic benefits of enterprises and reduce labor costs. The effect of labor intensity and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

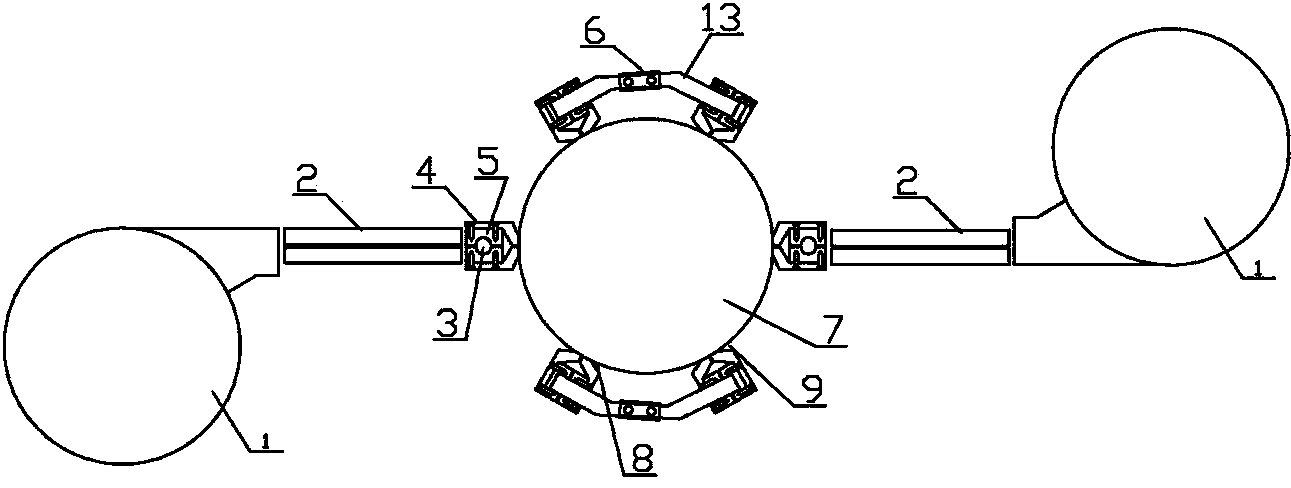

[0023] A method for stripping aluminum electrolytic capacitor bushings, which comprises the following steps:

[0024] ⑴Sorting: Arrange the aluminum electrolytic capacitors to be stripped in order;

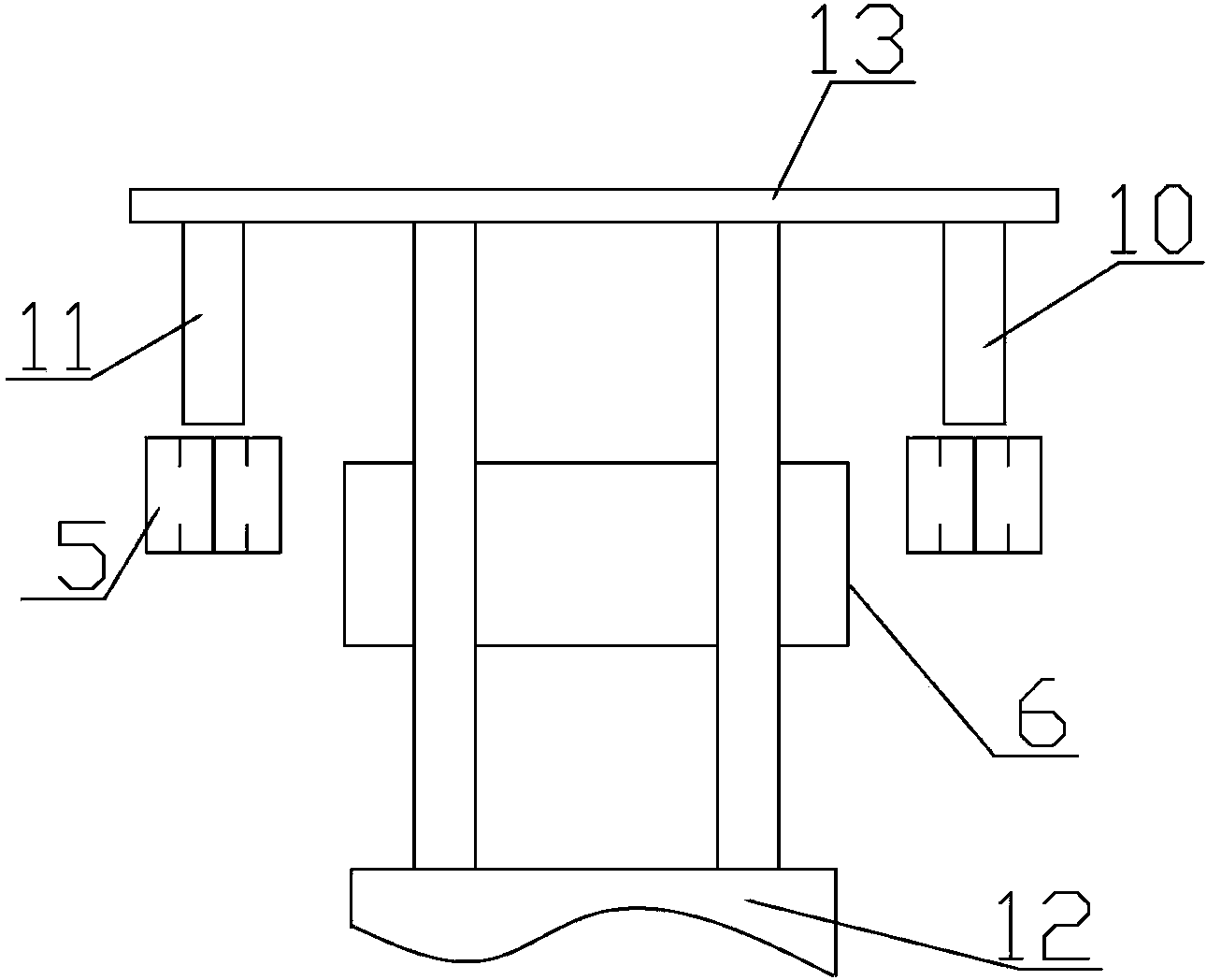

[0025] ⑵Heating: The aluminum electrolytic capacitors to be stripped sorted by step ⑴ are sequentially sent to the heating mechanism of the stripping device, and the aluminum electrolytic capacitors to be stripped are heated until the casing cracks;

[0026] (3) Separation: The aluminum electrolytic capacitors with cracked sleeves in step (2) are sequentially sent to the separation mechanism of the stripping device, and the aluminum electrolytic capacitors with cracked sleeves are separated from the heating mechanism.

[0027] In the present invention, in step (2), the heating temperature of the heating mechanism is 300°C-400°C, and the heating time is 0.5s-2 s.

[0028] The present invention adjusts the heating temperature and time according to the normal temperature-resistant g...

Embodiment 2

[0039] The normal temperature resistance grade of the bushing in this embodiment is 125°, therefore, the heating temperature of the heating mechanism in this embodiment is 400°C, and the heating time is 1.5s. According to the test, for the bushing with a normal temperature resistance level of 125°, the bushing will crack instantly under the above heating time and temperature, and it will not affect the internal quality of the capacitor, so that the use of the capacitor will not be shortened. life. The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com