Electric automobile charging gun structure

A technology for electric vehicles and charging guns, applied in electric vehicles, battery circuit devices, current collectors, etc., to prevent electromagnetic radiation and leakage, overcome the sharp drop in coupling coefficient, and achieve the effect of high coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

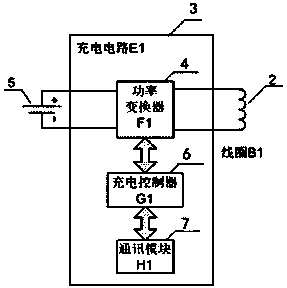

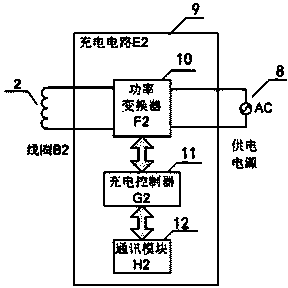

[0090] A charging device for an electric vehicle charging gun of the present invention includes the electrically isolated charging gun shown in Fig. 1 (a), (b) and Fig. 2 (a), (b) and such as Figure 5 with Image 6 Stationary and removable end charging systems shown. The fixed end Figure 1 (a), (b) and Figure 5 When installed inside the electric vehicle, the movable end Fig. 2(a), (b) and Image 6 Connect to the power supply 6 by wires. The specific implementation steps of electric vehicle charging are as follows:

[0091] Step 1. Insert the movable end of the charging gun into the fixed end, and the second magnetic conductor A2 becomes the "barrel cover" of the "barrel-shaped" first magnetic conductor A1, and the two induction coils B1 and B2 promptly becomes the two winding coils of a coupled high-frequency transformer, and the magnetic conductor 1 becomes the iron core of the high-frequency transformer;

[0092] Step 2: The fixed-end charging controller G1(6) detects t...

Embodiment 2

[0096] The charging device of another electric vehicle charging gun of the present invention includes the electrically isolated charging gun shown in Fig. 3 (a), (b) and Fig. 4 (a), (b) and such as Figure 5 with Image 6 Stationary and removable end charging systems shown. The fixed end Figure 3(a), (b) and Figure 5 When installed inside the electric vehicle, the movable end Figure 4(a), (b) and Image 6 Connect to the power supply 6 by wires. The specific implementation steps of electric vehicle charging are the same as those in Embodiment 1.

Embodiment 3

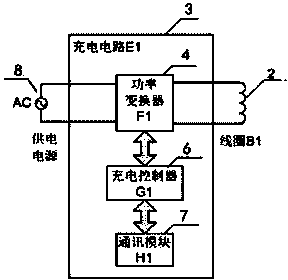

[0098] The charging device of another electric vehicle charging gun of the present invention includes the electrically isolated charging gun shown in Fig. 1 (a), (b) and Fig. 2 (a), (b) and such as Figure 7 with Figure 8 Stationary and removable end charging systems shown. The fixed end Figure 1 (a), (b) and Figure 7 is installed at the power supply end, the movable end Figure 2(a), (b) and Figure 8 placed on the side of the electric vehicle. The specific implementation steps of electric vehicle charging are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com