Glass article with photocatalyst film

A technology for photocatalyst films and articles, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, chemical/physical process, etc., can solve problems such as decrease in reflectivity, and achieve the effect of increasing transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] 22.5 g of ethylene glycol ethyl ether (manufactured by Sigma-Aldrich; organic solvent), 1.1 g of tetraethoxysilane (KBE-04 by Shin-Etsu Chemical Co., Ltd.; binder supply source), colloidal silica fine particles Dispersion (PL-7 manufactured by Fuso Chemical Industry Co., Ltd.; solid content concentration 22.9%, primary particle diameter (average particle diameter) 75nm, dispersion medium: water) 12.7g, titanium oxide fine particle dispersion liquid (solid content concentration 30%, primary particle diameter (average particle diameter) 10nm, dispersion medium: water) 2.2g, 1N hydrochloric acid (hydrolysis catalyst) 0.4g weighed in the glass container, it was stirred in the oven kept at 40 ℃ for 8 hours to obtain a high concentration solution. The solid content concentration in this high-concentration solution is 10%, and silicon oxide particles (colloidal silica particles), titanium oxide particles, and SiO 2 The mass ratio of the binder components is 75:17:8. Next, 234...

Embodiment 2~8 and comparative example 1~7

[0077] Except having changed the quantity of each component which comprises a coating liquid like description in Table 1, it carried out similarly to Example 1, and obtained the glass plate with a photocatalyst film. In addition, in some comparative examples, propylene glycol or 3-methoxybutanol was added to the coating liquid. Table 1 shows the evaluation results of the above characteristics. Also, use Figure 7 (comparative example 1) and Figure 9 (Comparative Example 5) shows the state obtained by observing the formed photocatalyst film with SEM, with Figure 8 (comparative example 1) and Figure 10 (Comparative example 5) shows the state which observed the formed photocatalyst film by AFM.

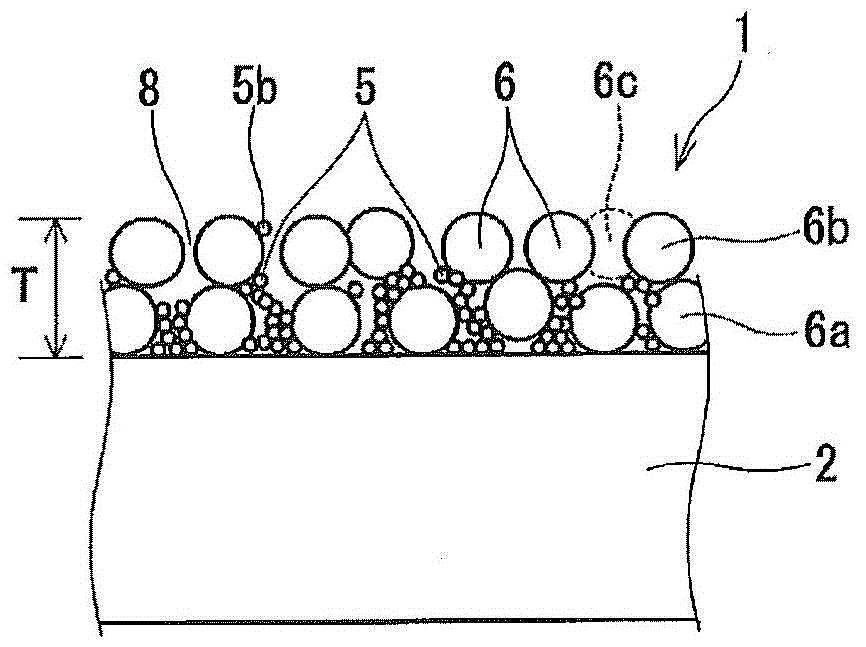

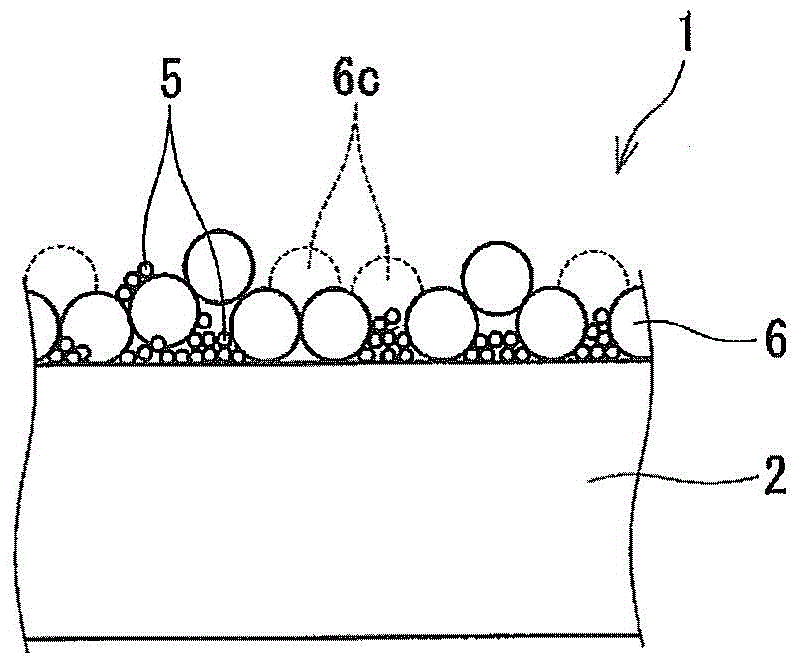

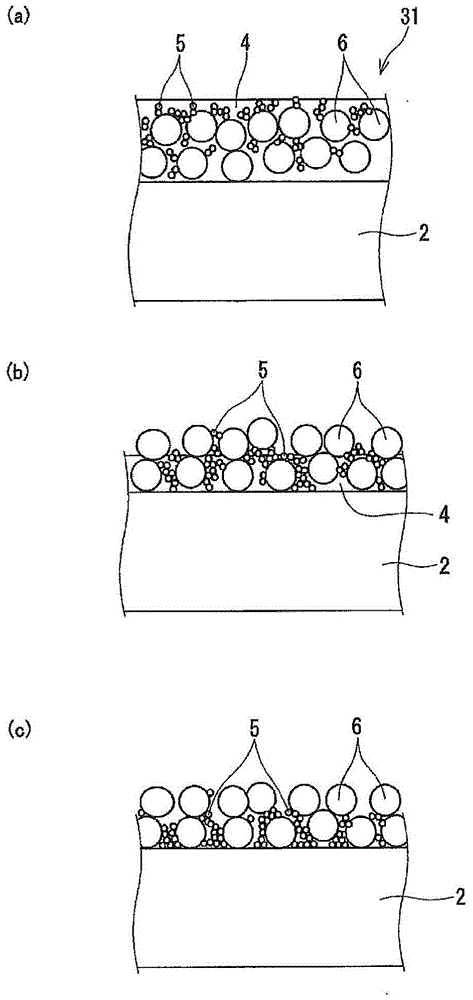

[0078] When the cross section of the glass plate with the photocatalyst film obtained by each Example was observed by SEM, it could be confirmed that in the photocatalyst film, more than 80% of the titanium oxide particles were concentrated in the lower 60% region of the film thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com