Resin sealing device and resin sealing method

A resin sealing device and resin sealing technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of difficult connector heating and prolonging the warm-up time, so as to suppress the temperature difference and prevent sudden The effect of heating or excessive heating and shortening the time required for preheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

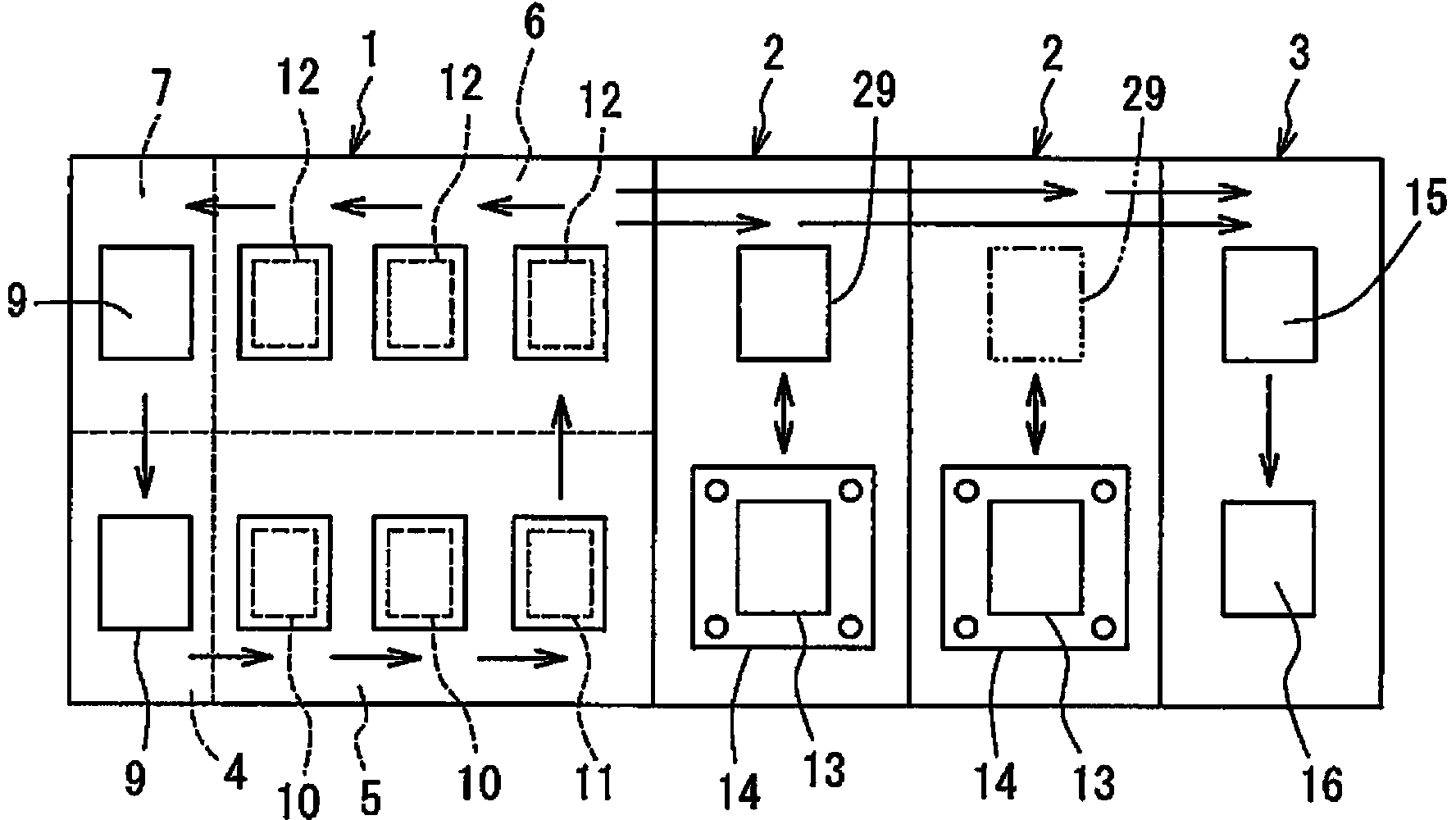

[0057] figure 1 It is a schematic plan view of a resin sealing device according to an embodiment of the present invention.

[0058] The resin sealing device of this embodiment includes a carry-in unit 1 , two molding units 2 , and a carry-out unit 3 . The carrying-in unit 1 receives the following object to be sealed (not shown) to be resin-sealed from the previous step. The molding unit 2 forms a resin sealed body by resin-sealing the body to be sealed received from the carry-in unit 1 . The carry-out unit 3 performs specific post-processing on the sealed resin body received from the molding unit 2 to complete individual packages, and sends these packages out.

[0059] The carrying-in unit 1 includes: a receiving unit 4, which receives the body to be sealed; a preheating unit 5, which preheats the body to be sealed; a tray cooling unit 6, which cools the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com