Power conversion device

A power conversion device and voltage technology, which is applied in the direction of circuit devices, emergency protection circuit devices, emergency protection devices with automatic disconnection, etc., can solve the problems of increased relay volume and resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The present invention will be described below using the drawings. In addition, the same reference numerals are attached to the common structures in each figure. In addition, this invention is not limited to the example shown in figure.

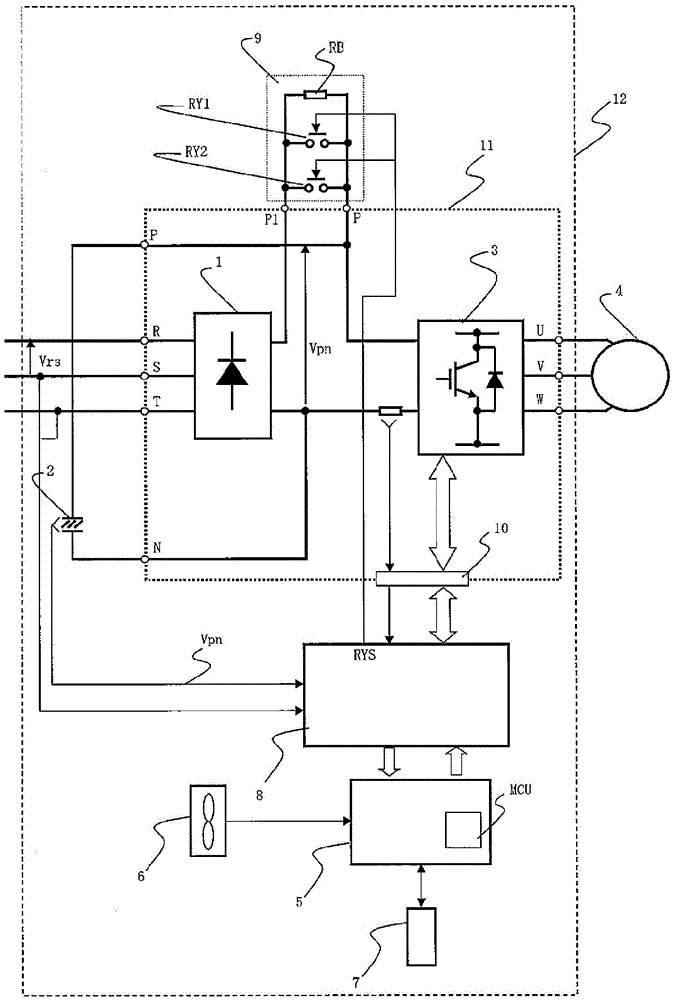

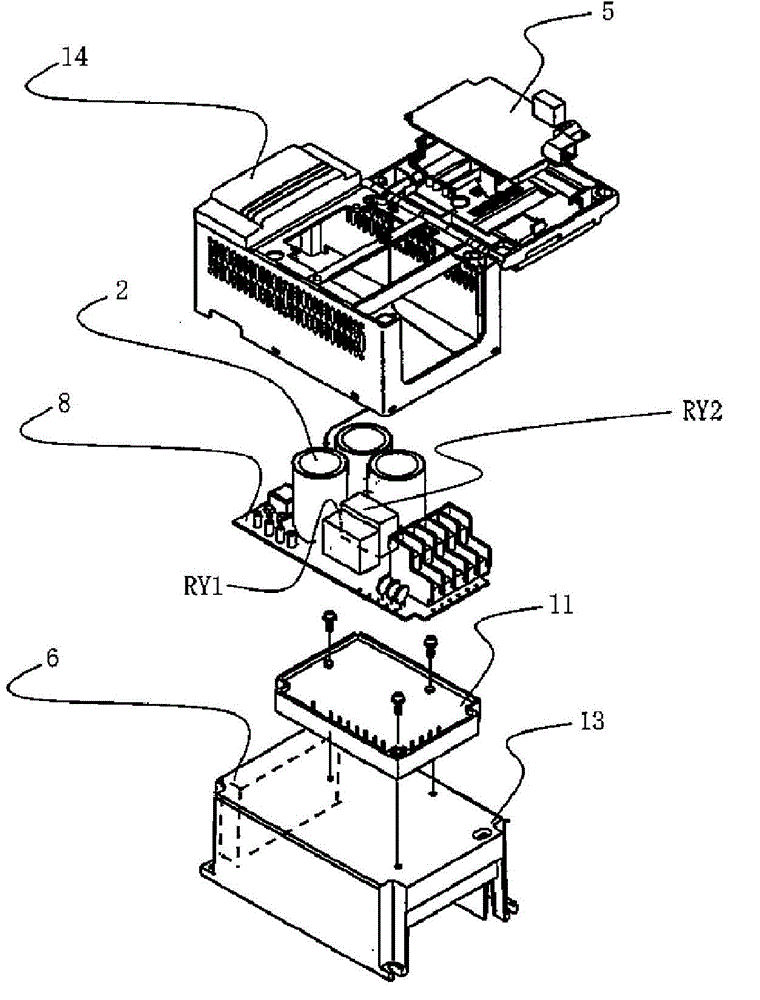

[0057] figure 1 A configuration diagram of a main circuit of the power conversion device 12 of the present embodiment is shown. 1 is a rectifier for converting AC power to DC power, 2 is a smoothing capacitor, 3 is an inverter for converting DC power to AC power of an arbitrary frequency, and 4 is an AC motor. 6 is a cooling fan for cooling the power semiconductor module 11 having the rectifier 1 and the inverter 3 .

[0058] 7 is a digital operation panel for setting and changing various control data of the power conversion device 12 and displaying abnormalities. The MCU, which is a microcomputer mounted in the control circuit 5 , performs calculations based on information stored in a storage unit storing various control data, and ...

Embodiment 2

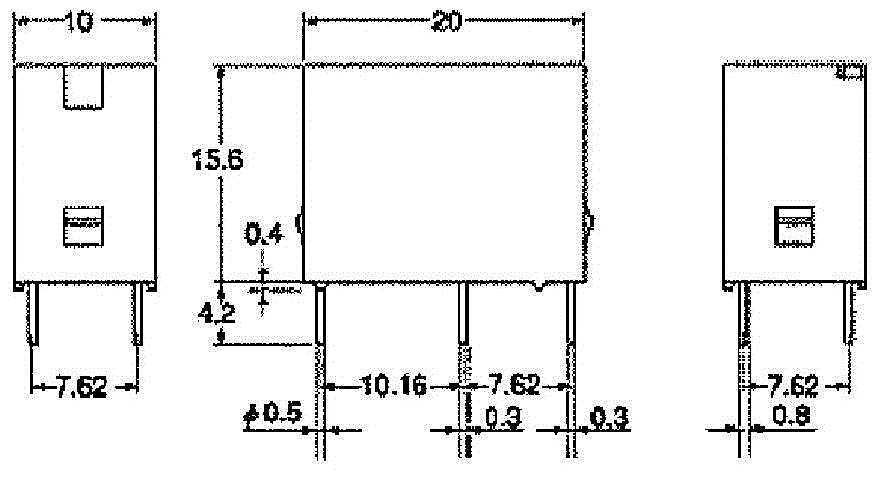

[0085] Fig. 6 is an example of a copper foil pattern on a substrate.

[0086] 6( a ) and ( b ) show enlarged parts where the relays are mounted among the components constituting the drive circuit 8 , and the bold black lines show copper foil patterns wired on the substrate, and current flows through the foil foil patterns.

[0087] An example is shown in which the lead terminals of the relays RY1 and RY2 are soldered through through holes provided on the substrate. Here, FIG. 6( a ) is an example of a copper foil pattern in which the distribution of the current flowing through the relays RY1 and RY2 connected in parallel is unbalanced.

[0088] The current I flowing through the relays RY1 and RY2 is inversely proportional to the impedance from the inflow point to the outflow point, that is, the wiring length of the copper foil pattern. If the cross-sectional area of the copper foil pattern is the same, the longer the wiring length, the higher the impedance and the smaller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com