Stirring feeding trolley

A locomotive and feeder technology, applied in the field of mixing and feeding vehicles, can solve the problems of difficult control of processing accuracy, insufficient power output, low feeding efficiency, etc., and meet the requirements of favorable feeding efficiency, stable discharge movement, and coaxiality. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

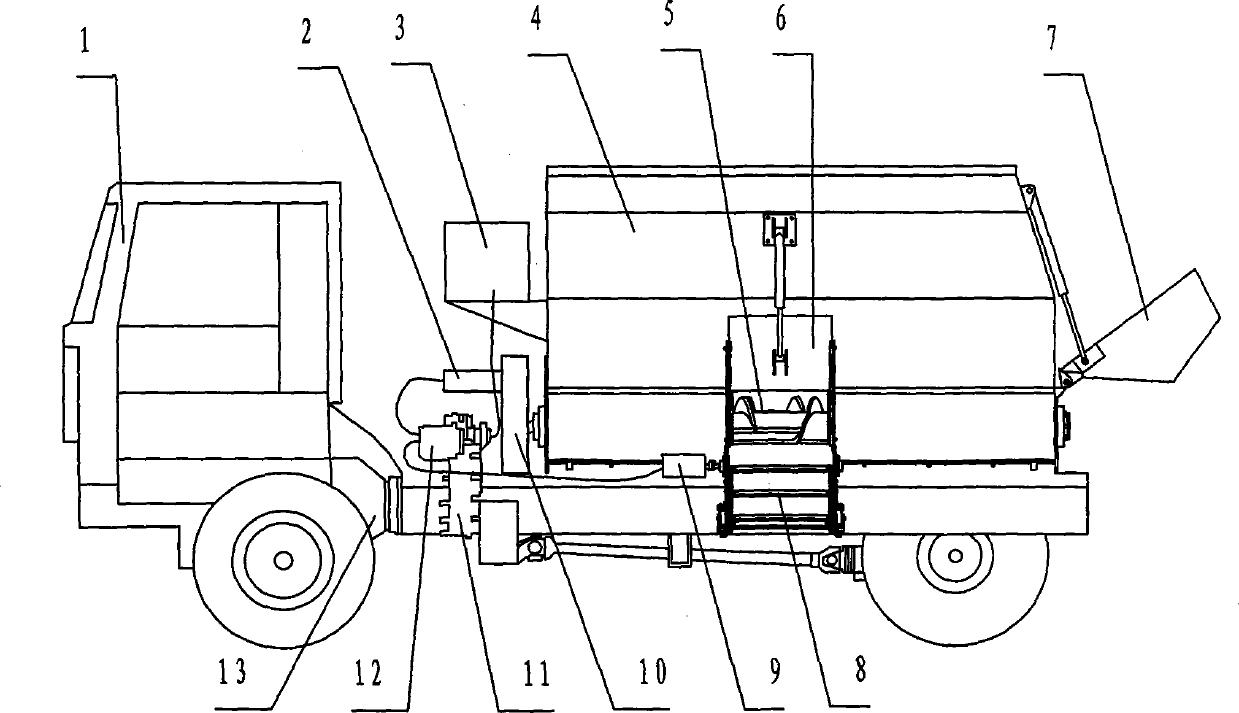

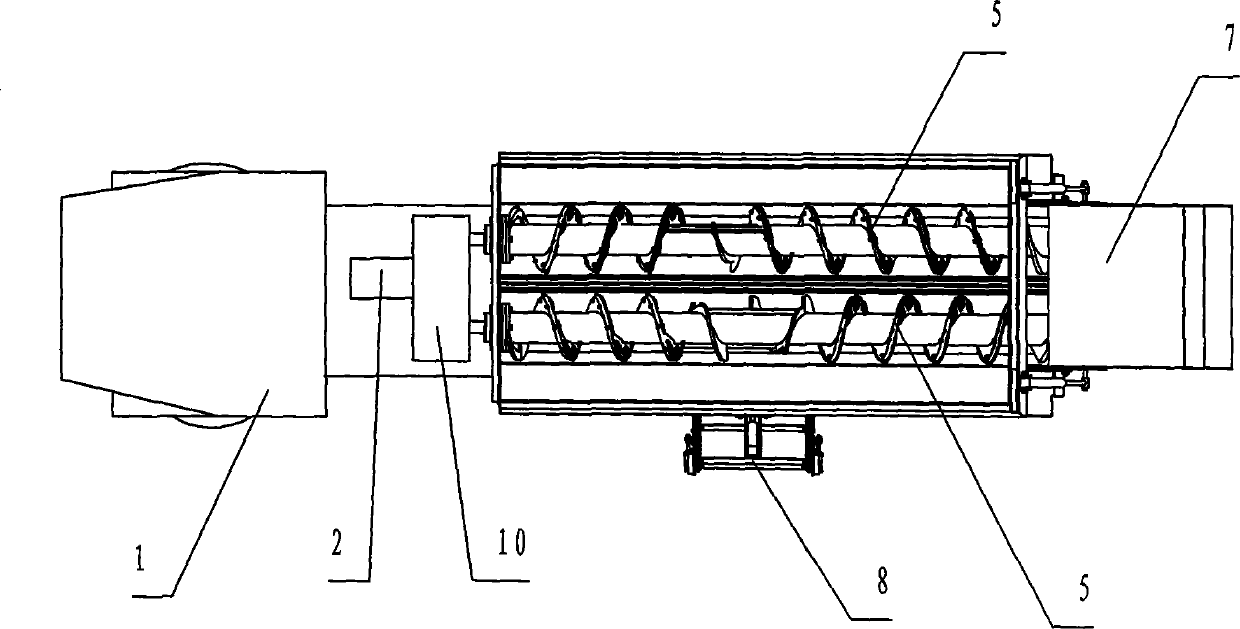

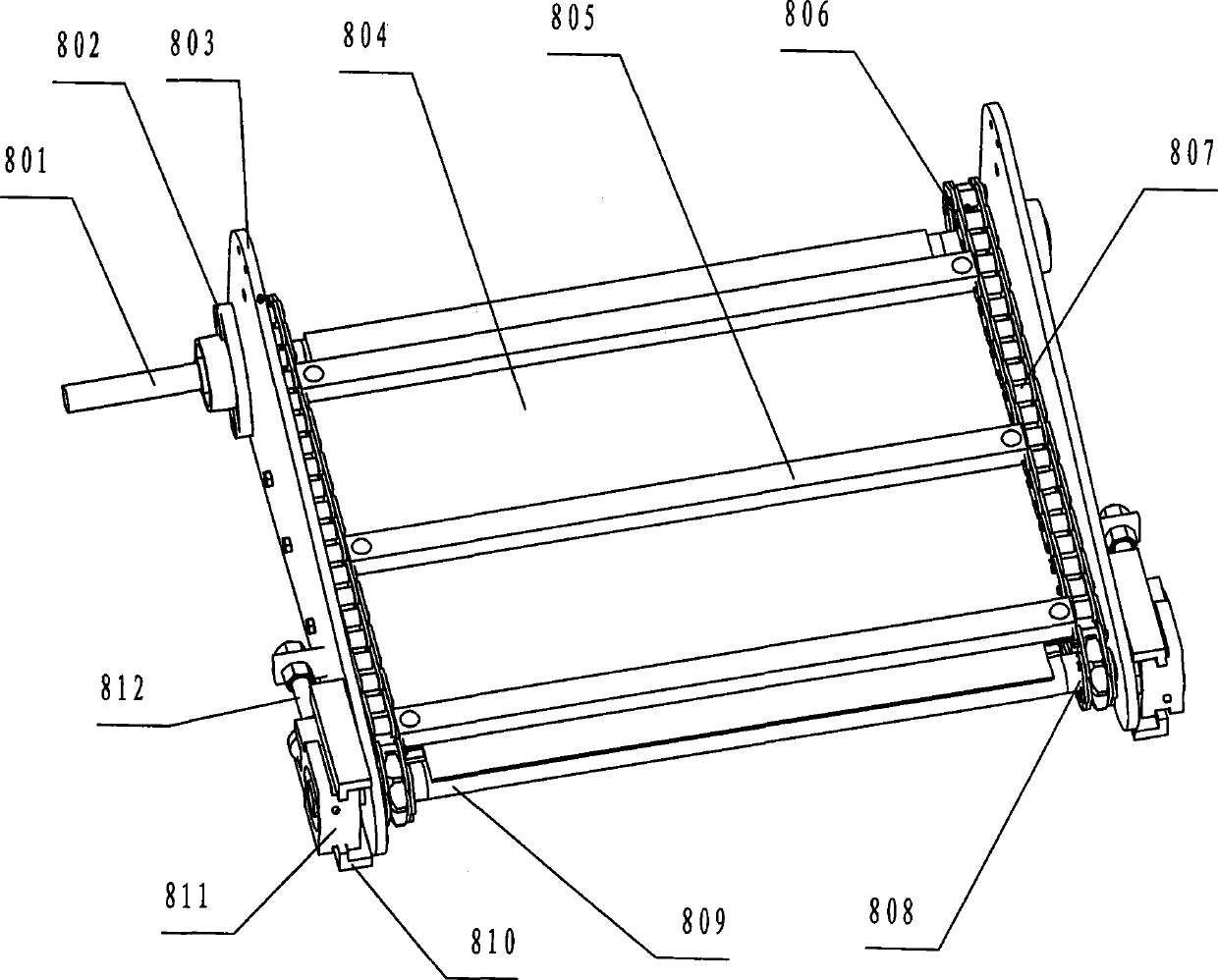

[0017] Embodiment: refer to attached Figure 1~3 , including a power locomotive 1, the power locomotive 1 is provided with a feed box 4, a pair of auger 5 for stirring feed is provided in the feed box 4, a feed hopper 7 is provided at the rear of the feed box 4, and a feed hopper 7 is provided at one side of the feed box 4. There is a discharge port, the discharge port is provided with a discharge port baffle 6, and a discharge hopper 8 is arranged under the discharge port baffle, and a sandwich force is provided between the engine 13 of the power locomotive 1 and the rear axle drive shaft 11, a hydraulic pump 12 is provided on the sandwich power take-off 11, a reduction box 10 is provided at one end of the auger 5, a hydraulic motor A2 is provided on the reduction box 10, and a hydraulic motor B9 is provided on one side of the discharge hopper 8 to obtain power. The material box 4 is provided with a hydraulic oil tank 3, and the hydraulic oil tank 3 stores the hydraulic oil r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com