A breeding and feeding system for feed processing and production

A matching and feed technology, applied in the field of animal husbandry, can solve the problems of not being able to meet the market demand, slow growth rate, and not meeting the purchasing power, etc., and achieve the effect of realizing small profits but quick turnover, keeping intact, and expanding the scale of pig farming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

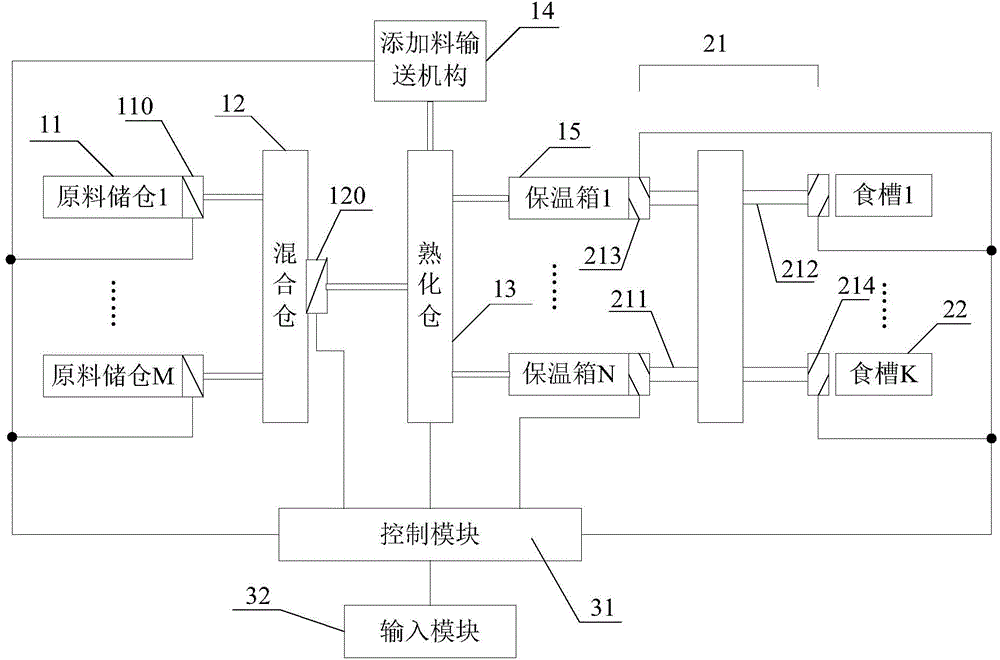

[0021] refer to figure 1 , a pig feed processing and production supporting breeding feeding system proposed by the present invention includes a feed production mechanism, a feed feeding mechanism and a control mechanism.

[0022] The feed production mechanism includes M raw material storage bins 11, a mixing bin 12, a maturing bin 13, an additive conveying mechanism 14 and N incubators 15.

[0023] Each raw material storage bin 11 is provided with a raw material discharge valve 110, and the M raw material storage bins 11 are connected to the mixing bin 12 through the raw material discharging valve 110, and the mixing bin 12 is provided with a mixed material discharging valve 120 and passes the mixed material The discharge valve 120 is connected to the curing bin 13, the feeding material conveying mechanism 14 is connected to the curing bin 13, and the curing bin 13 is connected to N incubators respectively.

[0024] The M raw material storage bins 11 are respectively used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com