Dedusting system of polishing chamber

A technology of dust removal system and grinding chamber, applied in the field of wood processing, can solve problems such as easy explosion, health hazards, danger, etc., and achieve the effects of avoiding physical health, reducing environmental pollution and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

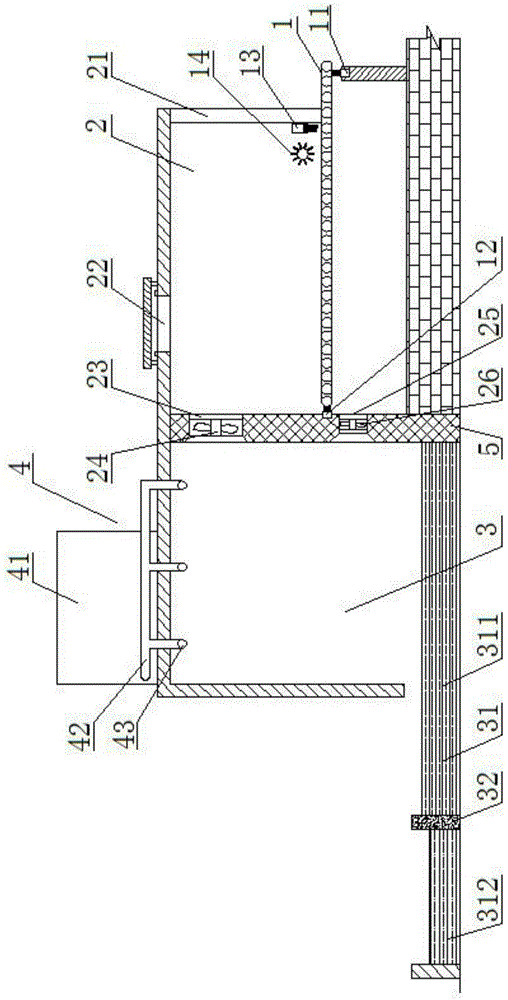

[0022] Such as figure 1 As shown, a grinding room dust removal system according to the present invention includes a conveyor belt 1, a grinding room 2, a dust removal room 3 and a partition wall 5, the dust removal room 3 and the grinding room 2 are separated by a partition wall 5, and the conveyor belt 1 Located in the middle and lower section of the grinding chamber 2, the top of the dust removal chamber 3 is provided with a spray system 4.

[0023] Described spray system 4 comprises reservoir 41, spray pipeline 42 and shower head 43, and reservoir 41 is positioned at the top of dedusting room 3, and spray pipeline 42 is communicated with reservoir 41, and shower nozzle is installed at outlet end of spray pipeline 42 43; the number of nozzles 43 is at least 3, and it can also be desi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com