A kind of preparation method of modified nano cotton oil-absorbing material

A technology of oil-absorbing materials and nano-cotton, which is applied in the fields of oil-absorbing materials and environmental protection, can solve the problems of less work reports, and achieve the effects of improved oil-absorbing selectivity, mild reaction conditions, and excellent oil-absorbing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 50 mL of water and 0.675 g of polyvinyl alcohol into the reaction vessel, raise the temperature to about 60° C. and stir to completely dissolve the polyvinyl alcohol. Add 0.45g block nano wool and stir. Raise the temperature to 80°C, add 5mL (4.5g) of butyl acrylate, 0.225g of benzoyl peroxide, and 0.2g of N,N-methylenebisacrylamide after the temperature stabilizes, and stop the reaction after stirring for 6h. The product was taken out, washed several times with water, and dried in vacuum until constant weight.

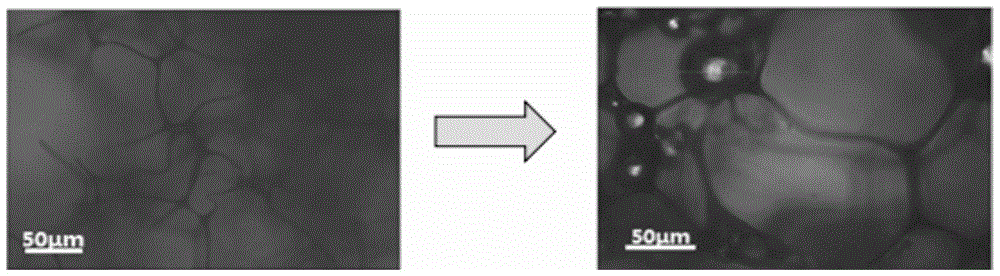

[0027] Such as figure 1 As shown, the left picture is the optical microscope image of the blank nano-cotton, the nano-cotton has a porous network structure. The picture on the right is an optical microscope image of the modified nano-cotton. It can be seen that there are some polyacrylate oil-absorbing resin particles in the network structure, which improves its oil-absorbing performance and oil-absorbing selectivity while retaining the porosity of the na...

Embodiment 2

[0029] Add 50mL of water and 1g of polyvinyl alcohol into the reactor, raise the temperature to about 60°C and stir to completely dissolve the polyvinyl alcohol. Add 0.55g block nano wool and stir. The temperature was raised to 85°C, and after the temperature stabilized, 10 mL (9 g) of butyl acrylate, 0.18 g of benzoyl peroxide, and 0.45 g of N,N-methylenebisacrylamide were added, and the reaction was stopped after stirring for 4 hours. The product was taken out, washed several times with water, and dried in vacuum until constant weight.

Embodiment 3

[0031] Add 50mL of water and 1g of polyvinyl alcohol into the reactor, raise the temperature to about 60°C and stir to completely dissolve the polyvinyl alcohol. Add 0.3g block nano wool and stir. The temperature was raised to 90°C, and after the temperature stabilized, 15 mL (13.5 g) of butyl acrylate, 0.27 g of benzoyl peroxide, and 0.135 g of N,N-methylenebisacrylamide were added, and the reaction was stopped after stirring for 8 hours. The product was taken out, washed several times with water, and dried in vacuum until constant weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com