Preparation method of cassava starch type high-water absorbency and oil-oil absorbency resin by cross-linked grafting technology

A technology of cassava starch and cross-linking grafting, which is applied in the field of preparation of cross-linking and grafting tapioca starch-type superabsorbent and oil-absorbing resins, can solve problems such as not being able to meet actual needs, achieve improved water-absorbing capacity and oil-absorbing capacity, and strong water-retaining performance and the effect of oil retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

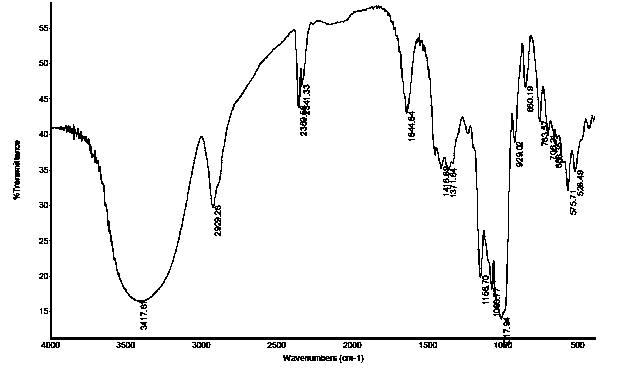

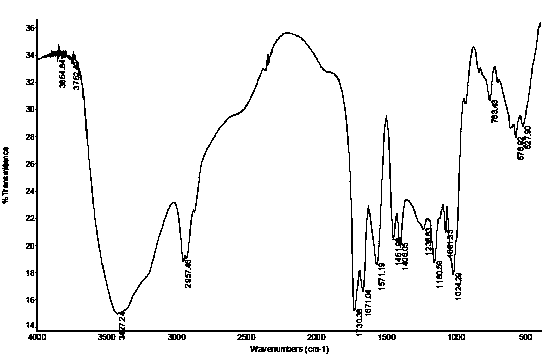

Image

Examples

Embodiment 1

[0037] (1) Dry 15 g of tapioca starch in a vacuum oven at 60°C to constant weight to obtain tapioca starch on a dry basis.

[0038] (2) Weigh 12g of dry base tapioca starch obtained in step (1) and 28mL of deionized water into a four-neck flask, start to heat up while stirring, stop heating when the temperature rises to 80°C, continue stirring for 20 minutes, and then start to cool down. Until the system temperature is 40°C, a gelatinized tapioca starch suspension with a mass fraction of 30% is obtained.

[0039] (3) Add 15g of solid sodium hydroxide and 35mL of deionized water into a 100mL beaker, stir and dissolve to obtain a 30% sodium hydroxide solution.

[0040] (4) Measure 11 mL of analytically pure acrylic acid and pour it into a beaker, gradually add the sodium hydroxide solution obtained in step (3) dropwise under stirring until the pH of the acrylic acid solution is 6; then add 15 mL of acrylamide with a mass fraction of 50% solution, stir well.

[0041] (5) Evenly...

Embodiment 2

[0048] (1) Dry 20 g of tapioca starch in a vacuum oven at 60°C to constant weight to obtain tapioca starch on a dry basis.

[0049] (2) Weigh 15g of dry base tapioca starch obtained in step (1) and 30mL of deionized water into a four-neck flask, start to heat up while stirring, stop heating when the temperature rises to 85°C, continue stirring for 30 minutes, and then start to cool down. Until the system temperature is 60°C, a gelatinized tapioca starch suspension with a mass fraction of 33.33% is obtained.

[0050] (3) Add 20g of solid sodium hydroxide and 30mL of deionized water into a 100mL beaker, stir and dissolve to obtain a sodium hydroxide solution with a mass fraction of 40%.

[0051] (4) Measure 12 mL of analytically pure acrylic acid and pour it into a beaker, gradually add the sodium hydroxide solution obtained in step (3) dropwise under stirring until the pH of the acrylic acid solution is 7; then add 20 mL of acrylamide with a mass fraction of 50% solution, stir w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com