A kind of efficient oil-water separation chitosan sponge and preparation method thereof

A technology of oil-water separation and chitosan, which is applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve the problem of less oil adsorption, and achieve the effects of strong oil retention capacity, low cost, and small environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Fully dissolve 2g of chitosan, 2mL of hydrochloric acid, and 100mL of deionized water under mechanical stirring (400r / min, stirring for 120min) to obtain a transparent chitosan solution; freeze the obtained chitosan solution at -20°C for 4h to form ice, and then freeze-dried at -56°C to obtain a chitosan porous sponge; the above 1cm 3 Soak the sponge in ethanol ammonia water mixture containing 0.2g tetramethoxysilane and 0.5g hexadecyltrimethoxysilane (9mL ethanol + 1mL ammonia water), carry out polymerization reaction at 50°C for 4h, and dry the sponge at 40°C for 12h , to obtain chitosan lipophilic hydrophobic sponge.

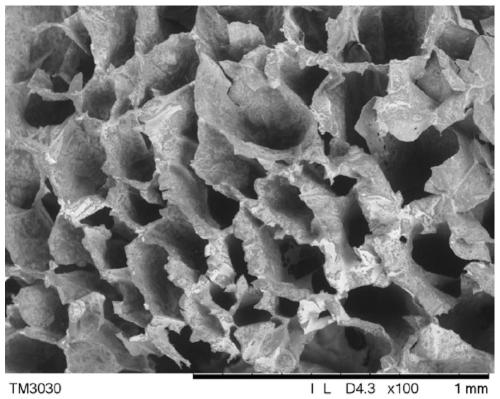

[0041] attached figure 1 It is the scanning electron micrograph of the chitosan porous sponge that embodiment 1 prepares. from figure 1 It can be seen that the pore structure is rich, and the pore size is between 250 and 500 μm, which is suitable for oil-water separation.

[0042] The obtained chitosan lipophilic and hydrophobic sponge was carried ...

Embodiment 2

[0044] Fully dissolve 1g of chitosan, 1.5mL of glacial acetic acid, and 100mL of deionized water under mechanical stirring (600r / min, stirring for 240min) to obtain a transparent chitosan solution; freeze the resulting chitosan solution at -40°C for 6h Freeze into ice, and then freeze-dry at -80°C to obtain a chitosan porous sponge; the above 1cm 3Soak the sponge in ethanol-ammonia water mixture containing 0.4g dimethylsiloxane and 0.6g vinyltrimethoxysilane (ethanol 8mL + ammonia water 2mL), polymerize at 60°C for 10h, dry the sponge at 60°C for 8h, Obtain chitosan lipophilic hydrophobic sponge.

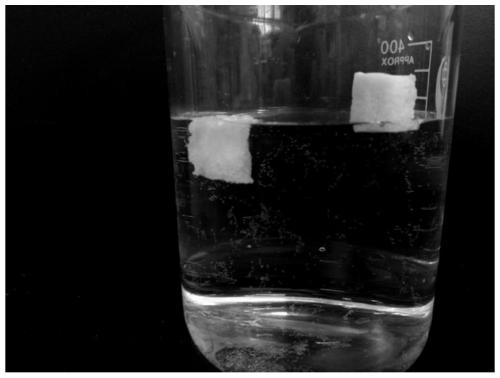

[0045] attached figure 2 The photos of the suspension situation in water before and after polysilane modification of the porous chitosan sponge prepared in Example 2. It can be seen that before modification, chitosan is hydrophilic and sinks into water. The modified chitosan sponge completely floated on the water surface, indicating its hydrophobic character.

[0046] The obtai...

Embodiment 3

[0048] Fully dissolve 0.5g chitosan, 1.5mL lactic acid, and 100mL deionized water under mechanical stirring (1000r / min, stirring for 480min) to obtain a transparent chitosan solution; freeze the obtained chitosan solution at -60°C for 8h Freeze into ice, and then freeze-dry at -80°C to obtain a chitosan porous sponge; the above 1cm 3 Soak the sponge in ethanol ammonia water mixture containing 0.5g propyltrimethoxysilane and 0.5g tetramethoxysilane (9.5mL ethanol + 0.5mL ammonia water), carry out polymerization reaction at 80°C for 5h, and dry the sponge at 80°C for 4h , to obtain chitosan lipophilic hydrophobic sponge.

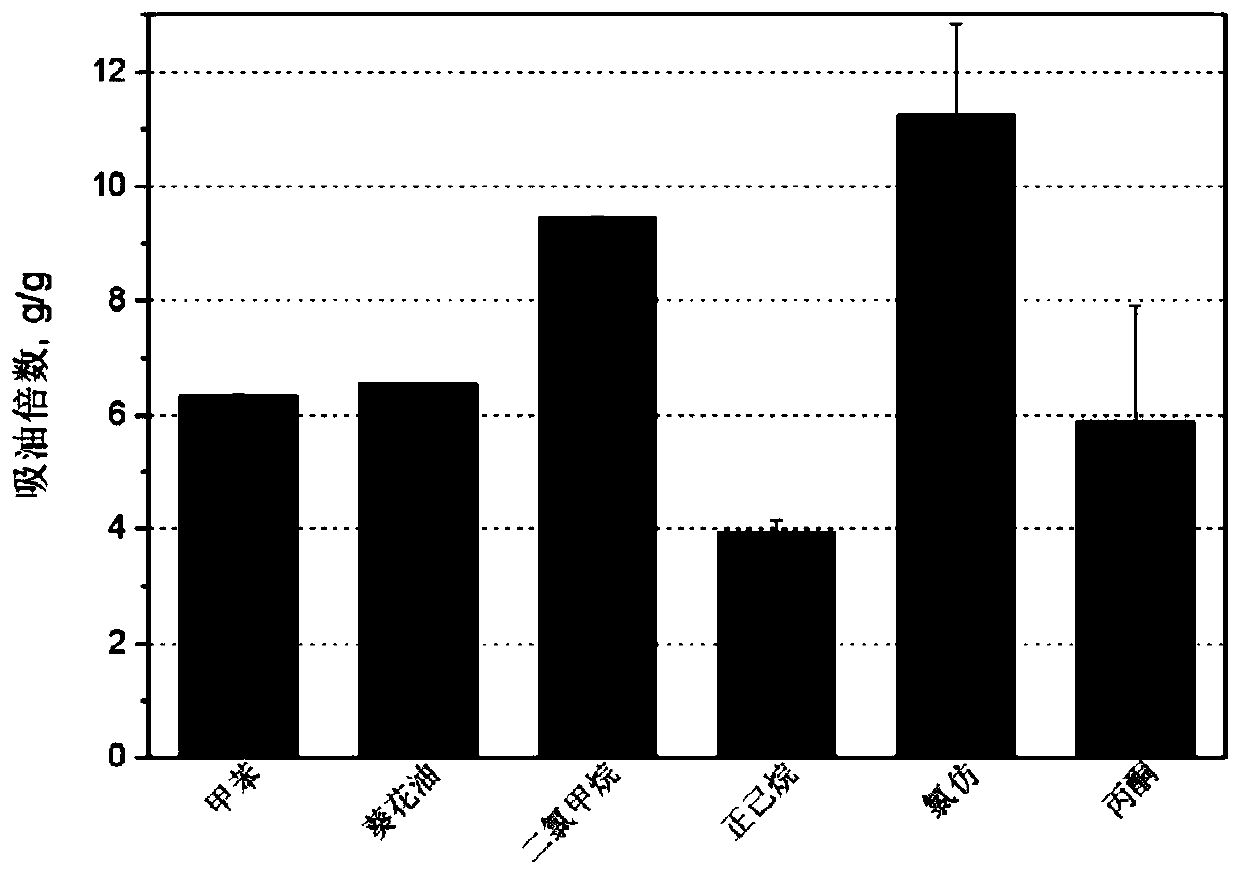

[0049] The obtained chitosan lipophilic hydrophobic sponge is carried out toluene, sunflower oil, dichloromethane, normal hexane, chloroform, the oil absorption multiple determination of acetone, the sponge is soaked in the above-mentioned liquid, after weighing the dry weight of contrast sponge and adsorption equilibrium the weight of.

[0050] attached i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com