A preparation method of melamine foam oil-absorbing material with improved toughness

A technology of melamine and oil-absorbing material, applied in the fields of oil-absorbing material and environmental protection, can solve problems such as high price and increase cost, and achieve the effects of improving tensile capacity, facilitating recycling and reuse, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Press the polypropylene into thin slices and cut it into small pieces, put it in toluene and heat it under reflux to dissolve it, then put it into the melamine foam, heat it under reflux and impregnate it for 30 minutes, then take out the melamine foam, remove the toluene solution in it, and put it in a dry box for 120 °C to constant weight. The mass percentage of polypropylene to toluene is 1%, and the mass ratio of polypropylene to melamine foam is 20:1.

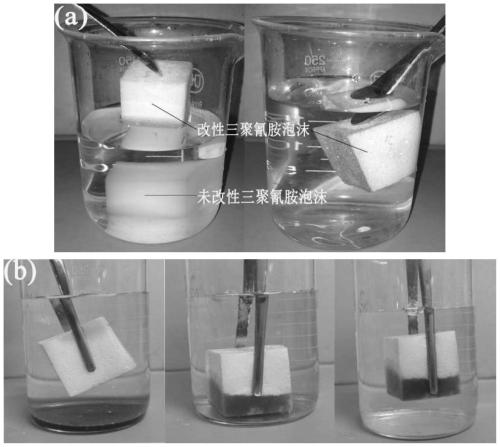

[0024] figure 1 (a) It can be seen that the melamine foam sinks to the bottom of the water, and the modified melamine foam obtained in Example 1 floats on the water surface, and the surface of the modified melamine foam is pressed into the water to have a phenomenon similar to a "silver mirror", and the foam is wrapped in water but does not absorb water. figure 1 (b) is the selective absorption test of the modified melamine foam obtained in Example 1 to the oil-water mixture. It can be seen from the figure that the...

Embodiment 2

[0027] Press the polypropylene into thin slices and cut into small pieces, put it in toluene and heat it under reflux to dissolve it, then put it into the melamine foam, heat it under reflux and soak it for 1 hour, then take out the melamine foam, remove the toluene solution in it, and put it in a dry box for 120 °C to constant weight. The mass percentage of polypropylene to toluene is 2%, and the mass ratio of polypropylene to melamine foam is 40:1.

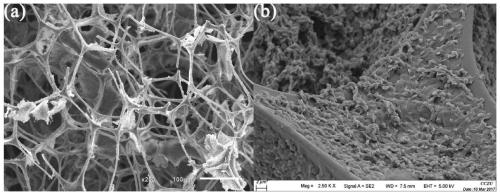

[0028] image 3 The scanning electron micrograph of the surface of the modified melamine foam prepared in Example 2. It can be seen from the figure (a) that the melamine foam still has a three-dimensional network structure, and polypropylene is adsorbed in its skeleton and pores. It can be seen from the figure (b) that the polypropylene adsorbed on the skeleton forms micron and nanoscale small protrusions, which makes the modified melamine foam have hydrophobic and lipophilic properties.

Embodiment 3

[0030] Press the polypropylene into thin slices and cut into small pieces, put it in xylene and heat it under reflux to dissolve it, then put it into the melamine foam, heat it under reflux and impregnate it for 45 minutes, then take out the melamine foam, remove the xylene solution in it, and put it in a dry box Dry at 120°C until constant weight. The mass percentage of polypropylene in xylene is 1.5%, and the mass ratio of polypropylene to melamine foam is 30:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com