Refrigerating machine oil

A technology for refrigerating machine oil and fatty acid, applied in the direction of lubricating composition, etc., can solve problems such as obstruction and poor compatibility, and achieve the effect of good compatibility and high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

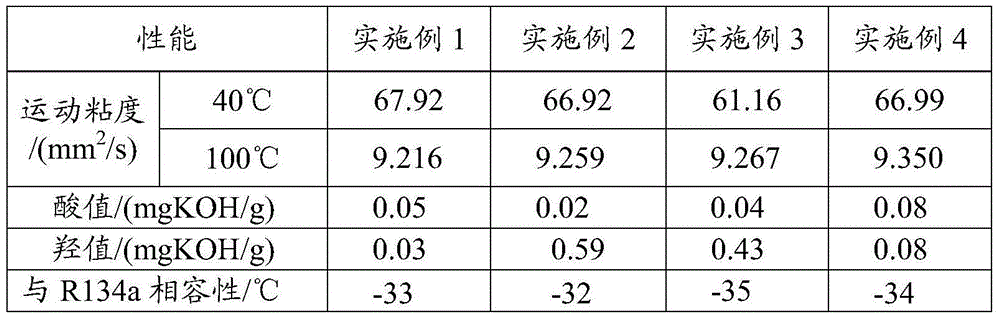

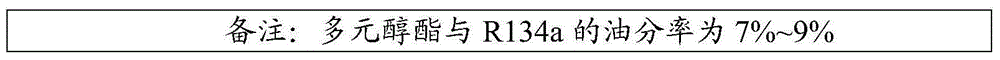

Examples

preparation example Construction

[0056] The preparation method of refrigerating machine oil provided by the invention is preferably:

[0057] The antioxidant, anticorrosion agent, antiwear agent, defoamer and polyol ester described in the above technical scheme are mixed to obtain the refrigerating machine oil.

[0058] The method of mixing the antioxidant, anti-corrosion agent, anti-wear agent, defoamer and polyol ester is not particularly limited in the present invention, and a mixing technical solution well known to those skilled in the art can be adopted. In the present invention, the consumption of described antioxidant, anticorrosion agent, antiwear agent, defoamer and polyol ester is the same as that of antioxidant, anticorrosion agent, antiwear agent, defoamer and polyol described in above-mentioned technical scheme The amount of ester is the same, and will not be repeated here.

[0059] In the present invention, the mixture of antioxidant, anticorrosion agent, antiwear agent, defoamer and polyol est...

Embodiment 1

[0066] 57.12g of monopentaerythritol, 71.12g of dipentaerythritol, valeric acid of 118.39g, heptanoic acid of 116.70g and nonanoic acid of 269.03g are added in the three-necked flask and mixed, and 25.29g of mass percentage concentration is 10% of After the sulfuric acid aqueous solution is stirred, the first heating is carried out for 5 hours under a vacuum of -0.07MPa, so that the temperature of the reaction system reaches 180°C to carry out the esterification reaction, and the esterification reaction product is obtained;

[0067] The above-mentioned esterification reaction product is subjected to a second heating for 4 hours under a vacuum of -0.08MPa, so that the temperature of the reaction system reaches 220°C to continue the esterification reaction;

[0068] After the esterification reaction is completed, the obtained reaction solution is evacuated to -0.093MPa for deacidification treatment, and the deacidification-treated reaction solution is filtered to obtain crude pol...

Embodiment 2

[0073] 147.68g of monopentaerythritol, 124.02g of 3-methylbutyric acid, 122.26g of 2-ethylpentanoic acid and 281.85g of 3,5,5-trimethylhexanoic acid were added to the three-necked flask and mixed, and the obtained After adding 51.24g of sulfuric acid aqueous solution with a mass percentage concentration of 5% in the mixture and stirring, the first heating was carried out for 3 hours under a vacuum of -0.05MPa, so that the temperature of the reaction system reached 170°C to carry out the esterification reaction, and the esterification reaction product was obtained ;

[0074] The above-mentioned esterification reaction product is subjected to the second heating for 2 hours under a vacuum of -0.06MPa, so that the temperature of the reaction system reaches 210°C to continue the esterification reaction;

[0075] After the esterification reaction, vacuumize the obtained reaction solution to -0.09MPa for deacidification treatment, filter the deacidification-treated reaction solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com