Streptomyces flavinus solid fermentation medium, preparation method and fermentation method thereof

A technology of Streptomyces flavinus and solid medium, applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of less proliferation and less spore production of Streptomyces flavinus, and achieve the growth rate and The effect of increasing spore production and increasing air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

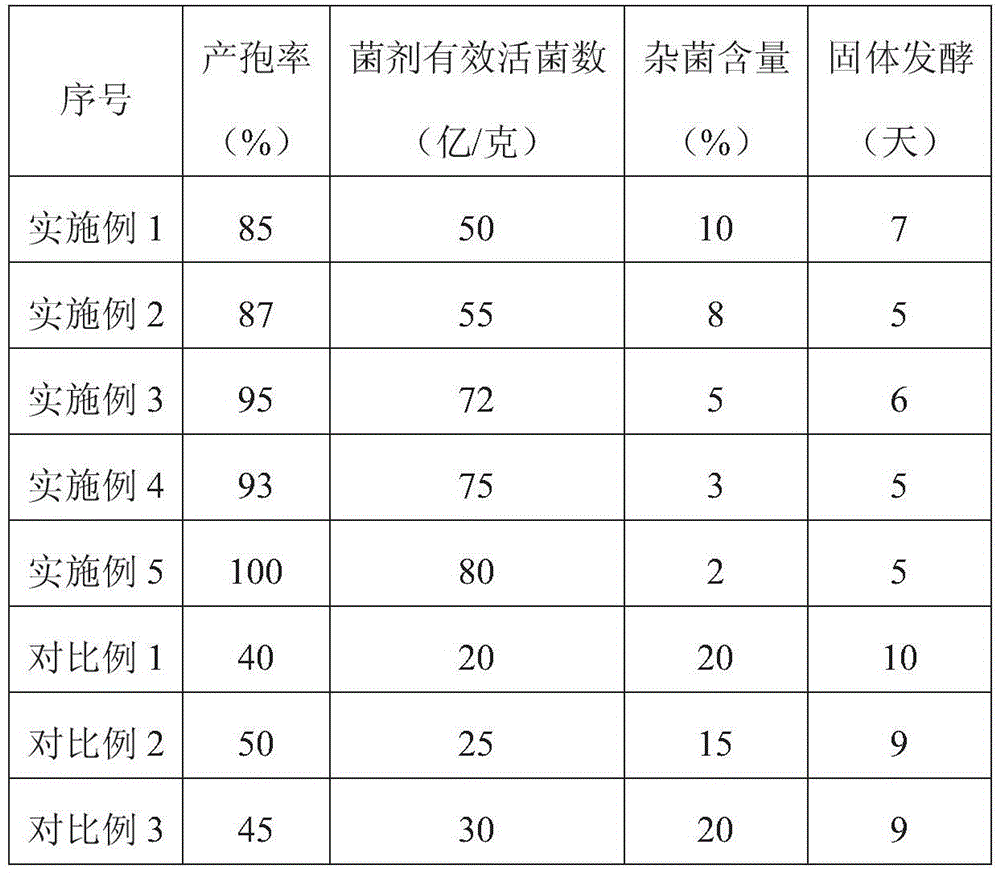

Examples

preparation example Construction

[0027] The present invention also provides a kind of preparation method of streptomyces flavinus solid culture medium on the other hand, comprises the following steps:

[0028] 1) Weighing corn flour, rice bran, sand and soil according to the above-mentioned ratio and mixing to obtain the mixture;

[0029] 2) Adding nutrient solution to the mixture, adjusting the pH value to 7.5-8.5, and sterilizing to obtain a solid medium.

[0030] Mix the corn flour, rice bran, and sand weighed according to the above ratio evenly, and adjust the pH value of the mixture to 7.5-8.5 after adding the nutrient solution. Adjusting the pH can be selected according to the pH of the resulting mixture. It is sufficient to avoid the introduction of acid or alkali that stimulates or poisons the growth of bacteria. Lime is preferably used, which is cheap, easy to obtain, and has little toxic effect on bacteria. The nutrient solution is preferably Gao's No. 1 culture solution.

[0031] Sterilization ...

Embodiment 1

[0047] Preparation method of culture medium:

[0048] 1) Weigh 30 parts by weight of corn flour, 10 parts by weight of rice bran, 30 parts by weight of sand and 15 parts by weight of peanut shells, wherein the sand is composed of fine soil and sand in a weight ratio of 3:1. The particle size of the fine soil is -60 mesh, and the particle size of the sand is -40 mesh. Mix the substances evenly;

[0049] 2) Add 25 parts by weight of potato sucrose culture solution, adjust the pH value to 7.5 with lime water, and apply 1.5kg / cm2 at 128°C 2 Pressure for 90 minutes to obtain a solid medium.

[0050] Fermentation method of Streptomyces luteus powder:

[0051] 1) Add appropriate amount of sterile water to the slant spores, the spores are evenly dispersed in the sterile water without agglomeration, and the spore suspension is made,

[0052] 2) Liquid fermentation: the bacterial suspension was inoculated into Gao's No. 1 culture medium, the inoculation amount was 8% of the volume o...

Embodiment 2

[0056] Preparation method of culture medium:

[0057] 1) Weigh 60 parts by weight of corn flour, 20 parts by weight of rice bran, 50 parts by weight of sand and 20 parts by weight of bean cake flour, wherein the sand is composed of fine soil and sand in a weight ratio of 5:1. The particle size of the fine soil is -60 mesh, and the particle size of the sand is -40 mesh. Mix the substances evenly;

[0058] 2) Add 25 parts by weight of potato sucrose culture solution, adjust the pH value to 8.5 with lime water, and apply 3kg / cm2 at 135°C 2 Pressure for 60 minutes to obtain a solid medium.

[0059] Fermentation method of Streptomyces luteus powder:

[0060] 1) Add appropriate amount of sterile water to the slant spores, the spores are evenly dispersed in the sterile water without agglomeration, and the spore suspension is made,

[0061] 2) liquid fermentation: the bacterial suspension was inoculated into Gao's No. 1 culture medium, the inoculation amount was 12% of the volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com