Six-linkage shedding mechanism for driving six heald frames

A technology of opening mechanism and six-bar linkage, which is applied in the direction of cam opening mechanism, textile, textile and paper making, etc., can solve problems such as difficulties, and achieve the effect of simple structure, small secondary force and smooth force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

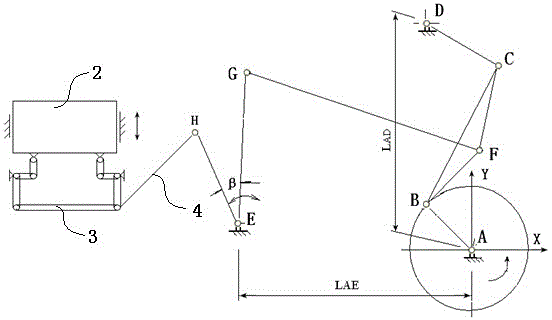

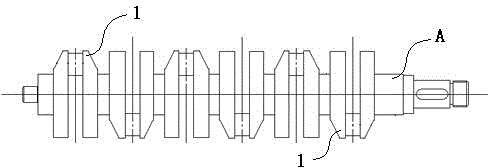

[0038] see figure 1 As shown, a six-link shedding mechanism for driving six-leaf heald frames is composed of a crankshaft A and six sets of six-link mechanisms with the same structure. The crankshaft A is provided with six gears with the same phase or with a difference of 180°. crank throw 1, the crankshaft A drives six sets of the six-link mechanism through the six crank throws 1, and each set of the six-link opening mechanism drives a heald frame through the middle rod 4 and the push rod group 3 2 up and down reciprocating motion;

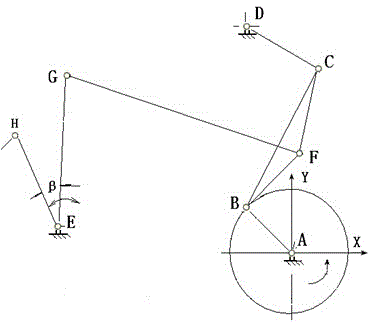

[0039] see figure 2 As shown, the six-bar linkage mechanism is composed of a crank-rocker mechanism ABCD and a double-rod assembly FGEH in series. The crank-rocker mechanism ABCD includes a crank AB, a connecting rod triangle BCF, and a rocker CD. One end of the crank AB Hinged on the crank throw 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com