Heat-preservation die and heat-preservation construction method for ultra-low temperature pipeline

A technology of pipeline thermal insulation and construction method, applied in pipeline protection, chemical instruments and methods, thermal insulation, etc., can solve the problems of pipeline frosting, falling off, asynchronous shrinkage and expansion rate of thermal insulation layer and pipeline, etc., to ensure integrity, guarantee The effect of synchronicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

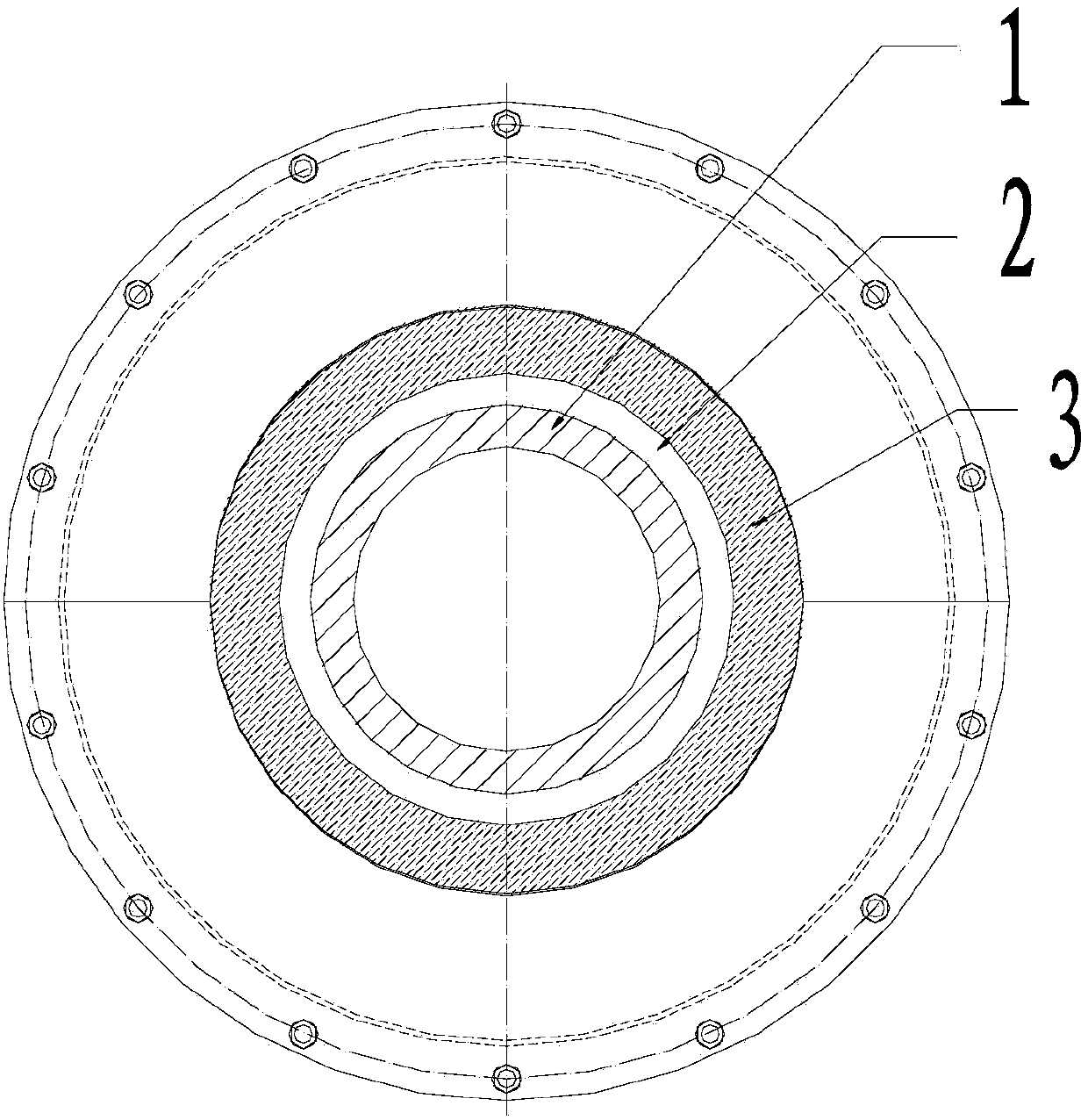

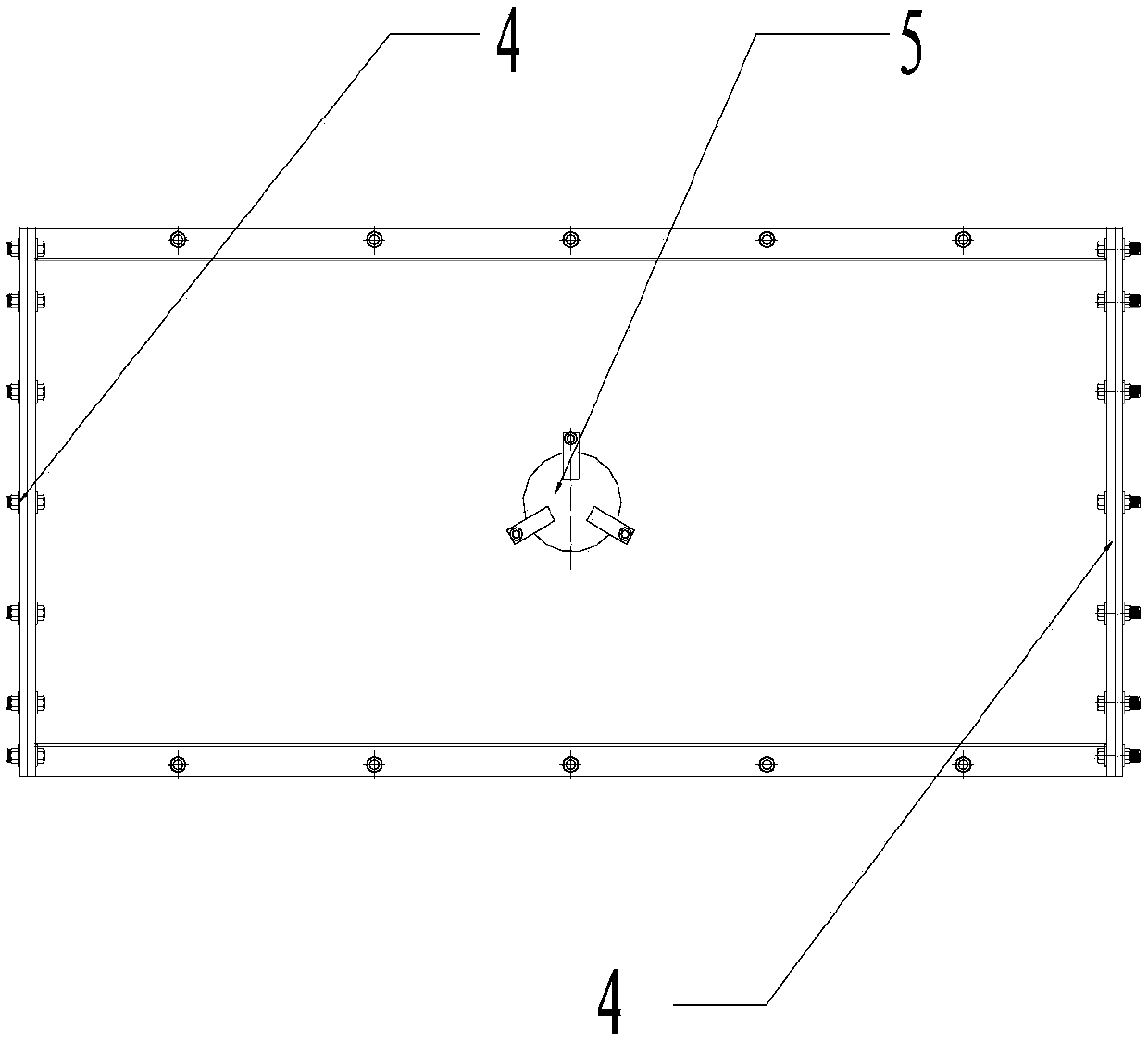

[0025] Such as figure 1 As shown, the ultra-low temperature pipeline 1 insulation mold of the present invention includes a mold body and a flange 4, the mold body is cylindrical, the flange 4 is arranged at both ends of the mold body, and a grouting port is also provided on the mold body 5.

[0026] During the specific implementation, according to the actual situation of the pipeline site, carefully review the pipeline size, distribute the mold length according to the appropriate distance, split it into several sections, and process the mold with thin steel plate according to the thickness of the outermost layer of heat preservation and the size of the pipeline, and use two pieces In the way of combining into pipelines, angle steel is welded into the style of flange 4 around each piece, and 10mm bolt holes are drilled at a distance of 100mm on the angle steel. The inner d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com