Built-in detection system for sulfur hexafluoride gas humidity

A technology of sulfur hexafluoride gas and detection system, applied in the direction of material water content, etc., can solve the problems of increased probability of flashover failure of insulators, low measurement accuracy, increased water content, etc., and achieve good measurement repeatability and stability. , High detection accuracy, high accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

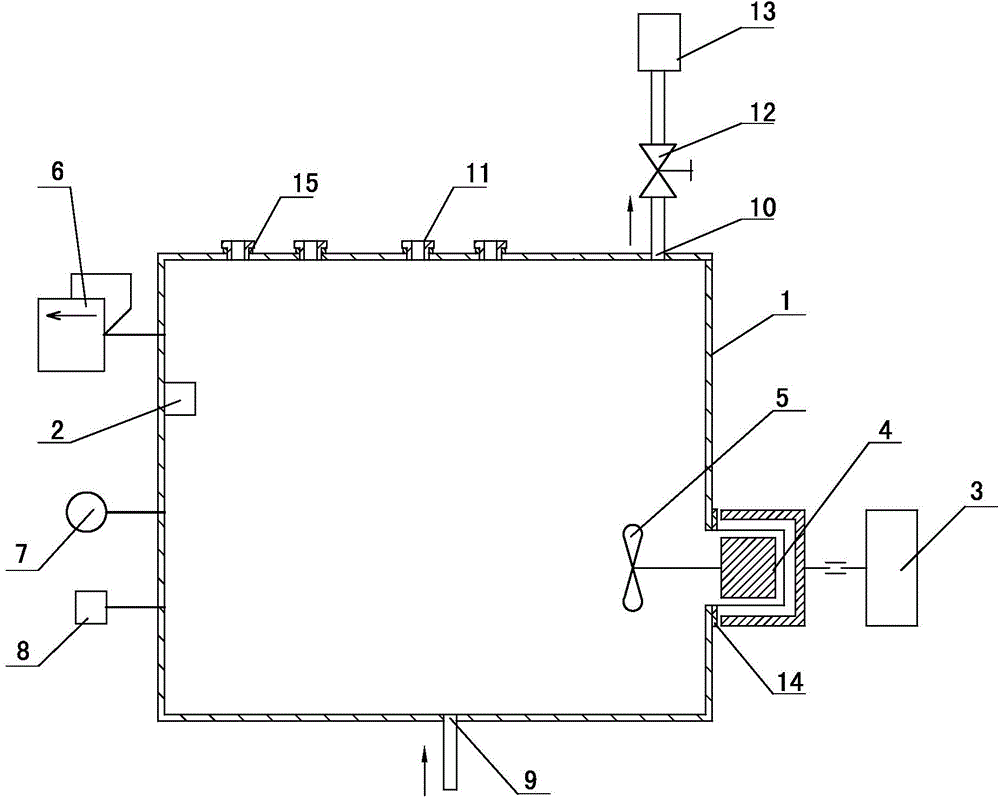

[0014] exist figure 1 In the shown embodiment: it includes a tank body 1, a mirror surface type sulfur hexafluoride humidity density sensor 2, a motor 3, a magnetic coupling 4 and a fan 5 arranged in the tank body 1, wherein the tank body 1 is provided with a safety Valve 6, pressure gauge 7, vacuum gauge 8, air inlet 9, air outlet 10 and 4 adapters 11 for installing the sulfur hexafluoride humidity sensor to be detected, and the mirror surface sulfur hexafluoride humidity density sensor 2 is installed on On the inner wall of the tank body 1, the air outlet 10 is connected to the dew point meter 13 through the valve 12, the magnetic coupling 4 is embedded in the tank body 1, the outer rotor of the magnetic coupling 4 is connected to the output shaft of the motor 3, and the inner rotor is connected to the fan 5 fixed connections. The connecting end of the adapter 11 and the tank body 1 is provided with an external thread, and the two are threaded through the gasket 15, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com