Material complex permittivity testing system and method with perforated short circuit plate

A complex dielectric constant and testing system technology, which is applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of easy damage of screws, damage of waveguide and short circuit board, inconvenience of sample insertion, etc., to achieve Easy to use, reduce system error, and facilitate the effect of vacuuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

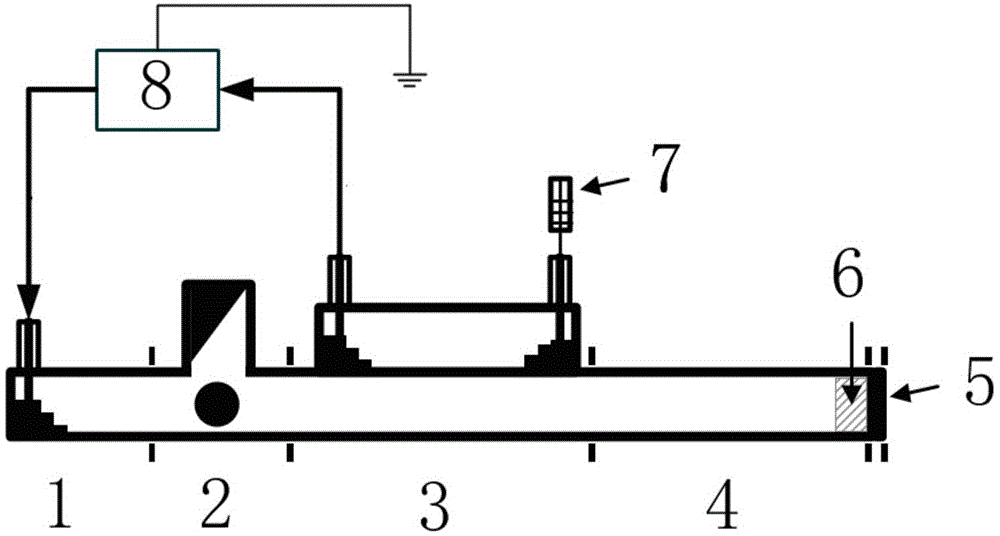

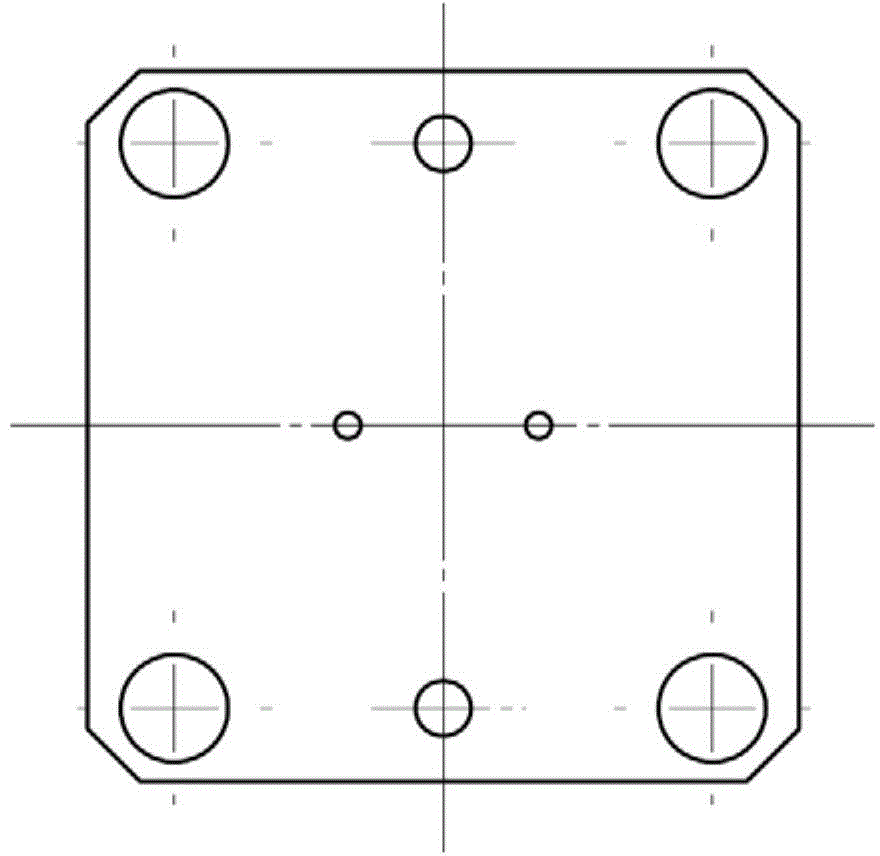

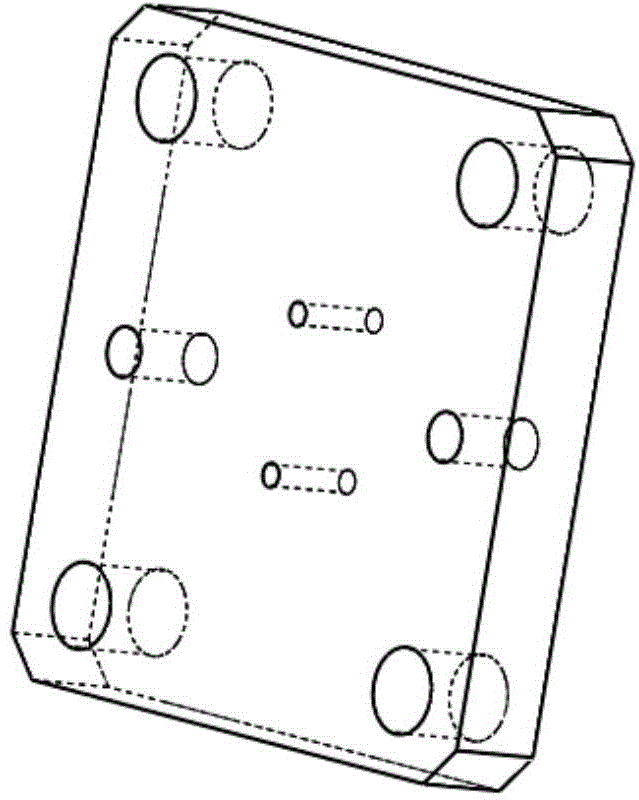

[0019] Material complex permittivity test system with open-hole short-circuit board, such as figure 1 As shown, it includes a sequentially connected coaxial cable to a rectangular waveguide conversion joint 1, an isolator 2, a bidirectional coupler 3, a rectangular waveguide 4 and a short circuit board 5; it also includes a vector network analyzer 8, and the output of the vector network analyzer 8 The test signal of the test signal is connected to the conversion joint 1 from the coaxial cable to the rectangular waveguide through the signal input coaxial cable, and the coupling end output test signal of the bidirectional coupler 3 away from the short circuit board 5 is input to the vector network analyzer 8 through the signal output coaxial cable, The coupling end of the bidirectional coupler 3 close to the short circuit board 5 is connected with a matching load 7; the middle area of the short circuit board 5 has a through hole.

[0020] Further, in the above-mentioned materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com