Method for monitoring environment of textile workshop

A technology of environmental monitoring and workshop, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of managers who are exhausted, prone to pharyngitis, skin diseases, and high dust concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

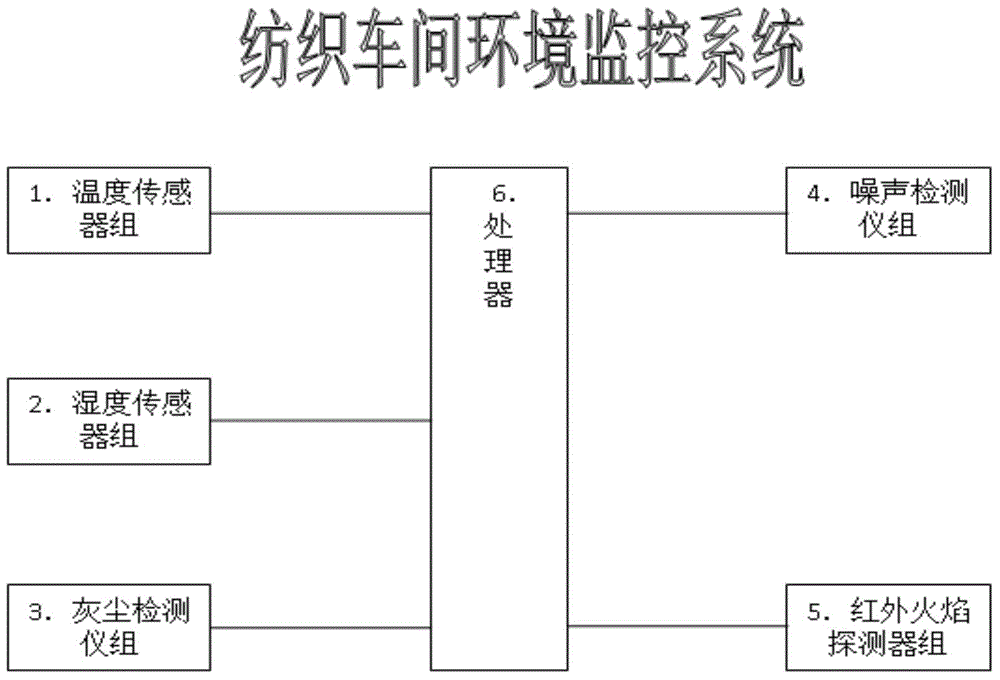

[0015] The implementation of the textile workshop environment monitoring system of the present invention will be described in detail below with reference to the accompanying drawings.

[0016] A textile workshop refers to a workshop that uses machinery to manufacture means of production or means of living, and is a place where textile raw materials are processed and manufactured. Due to the particularity of the industry, textile workshops need to monitor a variety of parameters, some of which are related to the health of textile workers, such as noise, dust concentration, temperature and humidity. Naturally, dust concentration is also related to the qualified rate of textiles. Some monitoring objects are related to workshop equipment maintenance, for example, flame detection and so on. Ineffective monitoring of noise, dust concentration, temperature and humidity can easily cause textile workers to suffer from occupational diseases such as itchy throat and skin diseases, and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com