Central vacuumizing impregnation system and control method thereof

A central control system and vacuum pumping technology, which is applied in the direction of drying/impregnating machines, electrical components, electrolytic capacitors, etc., can solve the problems of uneven dipping quality of capacitor cores, low production efficiency, and affecting the dipping quality of capacitor cores, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

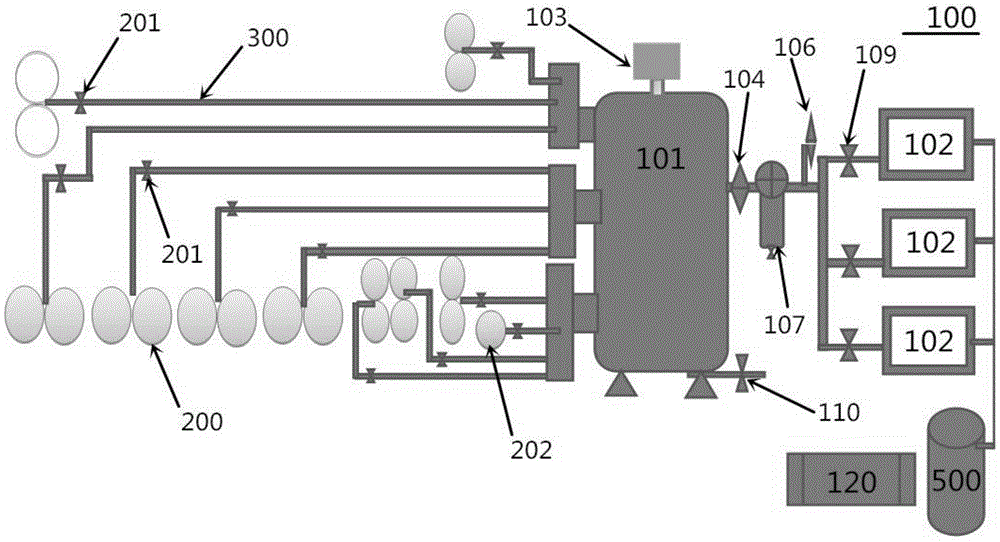

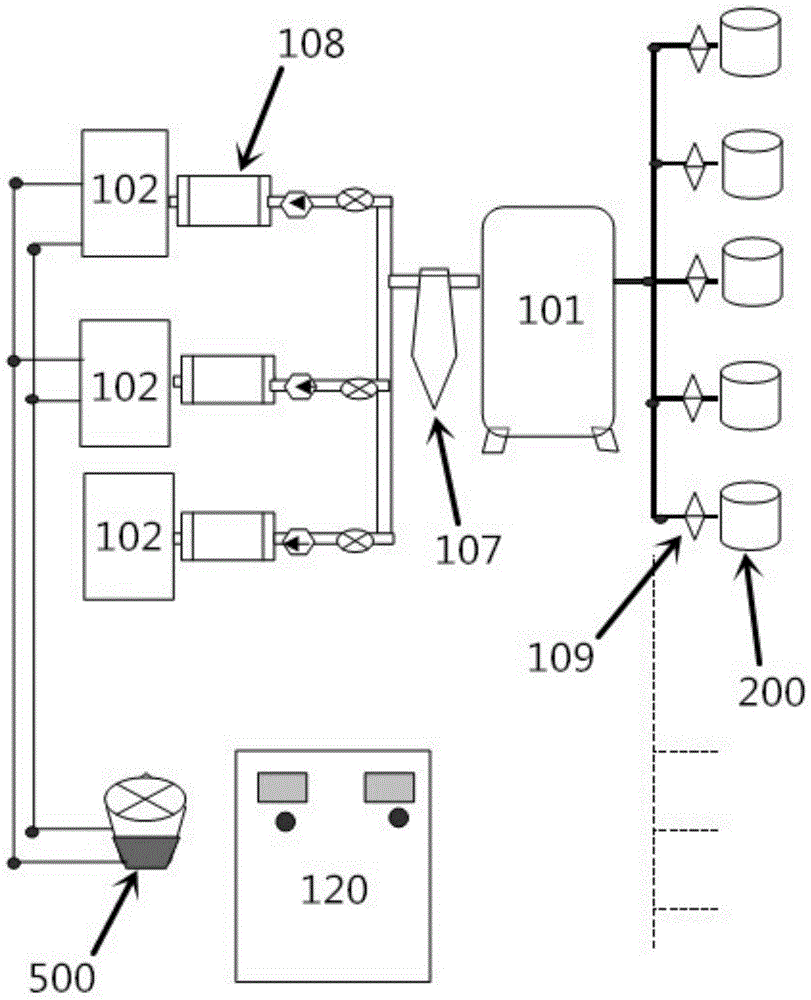

[0029] Such as figure 1 As shown, a central vacuum impregnation system includes a central control system 100 and several impregnation machines 200. The central control system 100 includes a vacuum storage cylinder 101, a vacuum machine 102, an electric control box 120, and a vacuum monitor 103. The electric control box 120 is provided with a PLC control module (not shown in the figure), and the vacuum monitor 103 is installed on the vacuum storage cylinder 101 and can monitor the internal vacuum level of the vacuum storage cylinder 101, specifically the vacuum value or air pressure value. Each impregnation machine 200 is independently connected to the vacuum storage cylinder 101 through pipelines, and the pipelines between each impregnation machine 200 and the vacuum storage cylinder 101 are respectively provided with valves 201 . The vacuum storage cylinder 101 is connected to the suction end of the vacuum machine 102 through a pipeline, and the pipeline between the vacuum st...

Embodiment 2

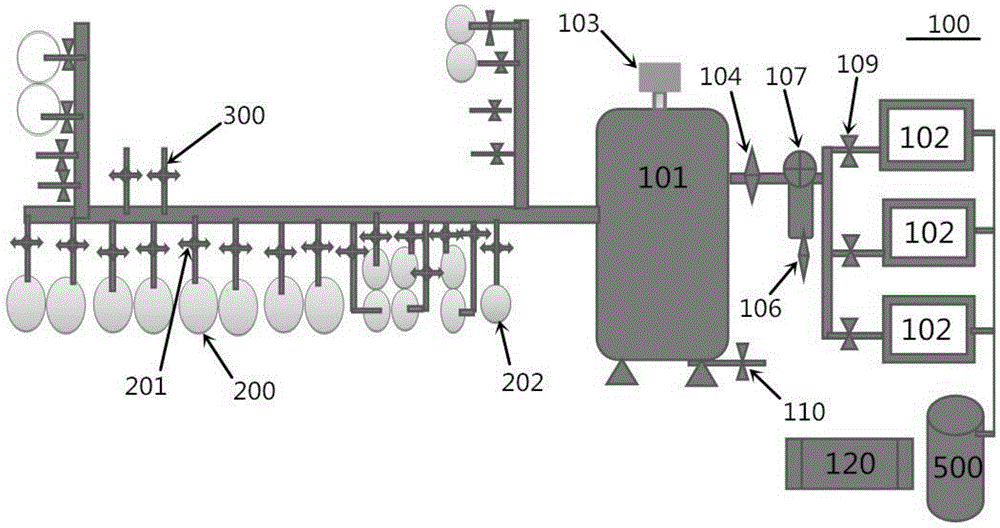

[0040] This embodiment is similar to Embodiment 1, the difference is that, as image 3 As shown, the vacuum storage cylinder 101 is externally connected to a central pipeline 400 with a larger diameter, each impregnation machine 200 is connected to the central pipeline 400 through a pipeline 401 with a smaller diameter, and each valve 201 is respectively set on each pipeline 401. In addition, the air vent 105 is arranged on the exhaust port of the liquid-gas separator 107 , and the second control valve 106 is installed on the exhaust port of the liquid-gas separator 107 . Parts not mentioned in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0041] A control method based on the central vacuum impregnation system of the present invention comprises the following steps:

[0042] S1: Preset the upper limit and lower limit of the vacuum value in the vacuum monitor 103, so that the vacuum detector 103 when the vacuum value of the vacuum stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com