Waste gasification melting furnace

A technology of gasification, melting and waste, applied in incinerators, indirect carbon dioxide emission reduction, combustion methods, etc., can solve problems such as high operating costs and increased emissions, and achieve the effects of reducing consumption, reducing combustion load, and suppressing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Next, a waste gasification melting furnace according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings. However, the embodiments described below do not limit the technical scope of the present invention.

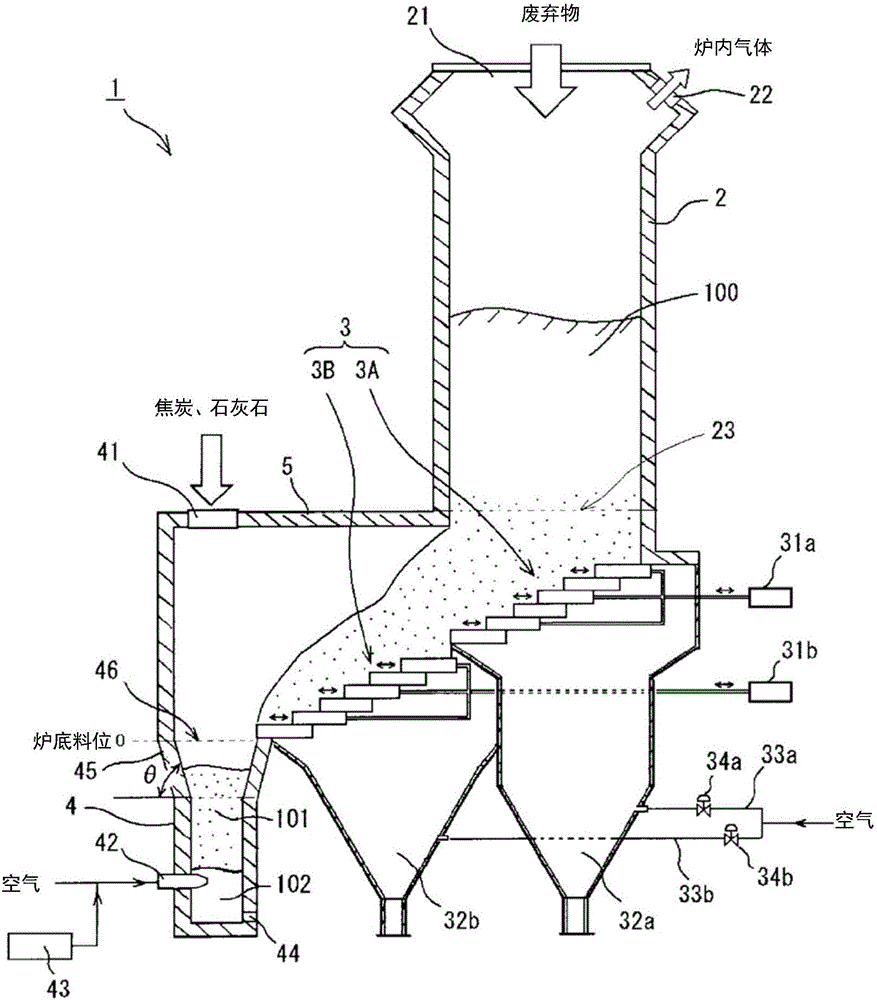

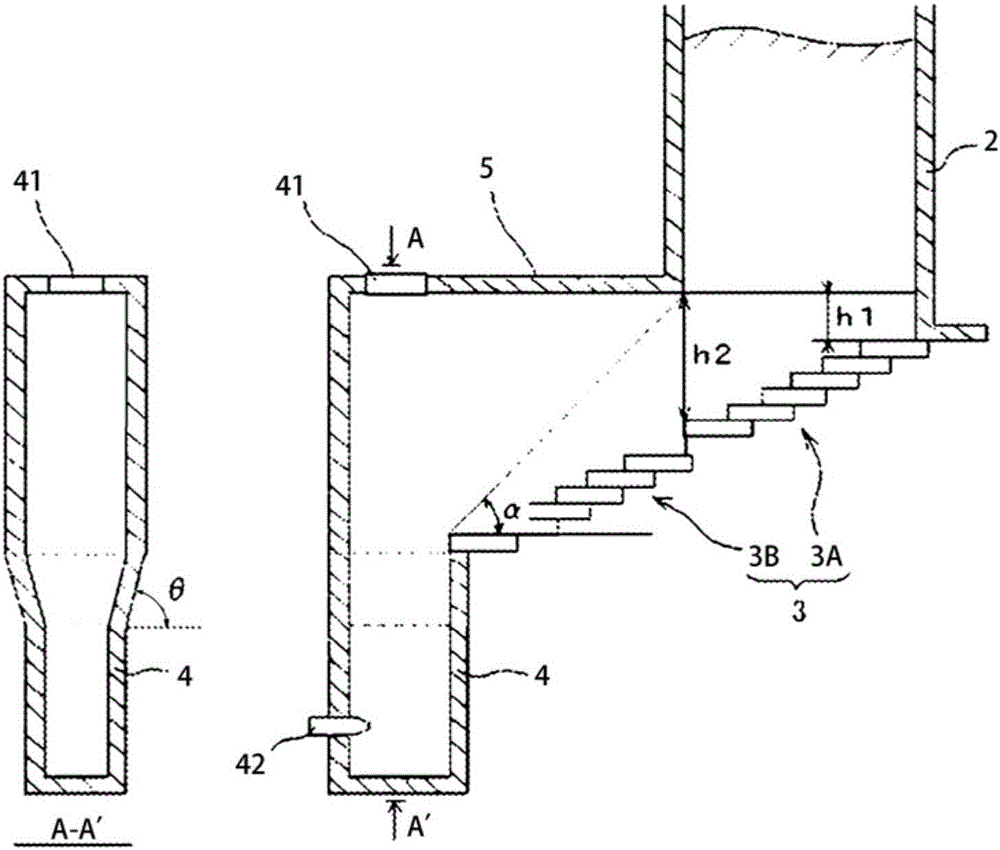

[0050] figure 1 A longitudinal sectional view showing the waste gasification melting furnace of this embodiment. The waste gasification melting furnace 1 includes, for example, a vertical shaft part 2 for drying / thermally decomposing waste in a reducing atmosphere; a carbonization furnace grate part 3 for further thermally decomposing the dried / thermally decomposed waste and generating carbonized waste; The melting furnace section 4 further burns / melts the charred waste. The shaft part 2 and the melting furnace part 4 are offset relative to the furnace core in the lateral direction, and the bottom side opening of the shaft part 2 and the upper side opening of the melting furnace part 4 are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com