Propolis extraction method

A technology for propolis and extraction liquid, applied in the field of edible alcohol and water extraction of propolis, can solve the problems of lack of extraction steps of propolis water-soluble substances, unsatisfactory lead removal effect, potential safety hazard, etc., so as to improve production efficiency and materials. Effectiveness of utilization rate, improved food safety, improved safety and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Low-temperature crushing and sieving

[0039] Put 100kg of wool gum purchased from a beekeeping cooperative into a low-temperature pulverizer, pulverize at -5°C to 10-mesh particles, and pass through a 5-mesh stainless steel screen to obtain hair glue particles.

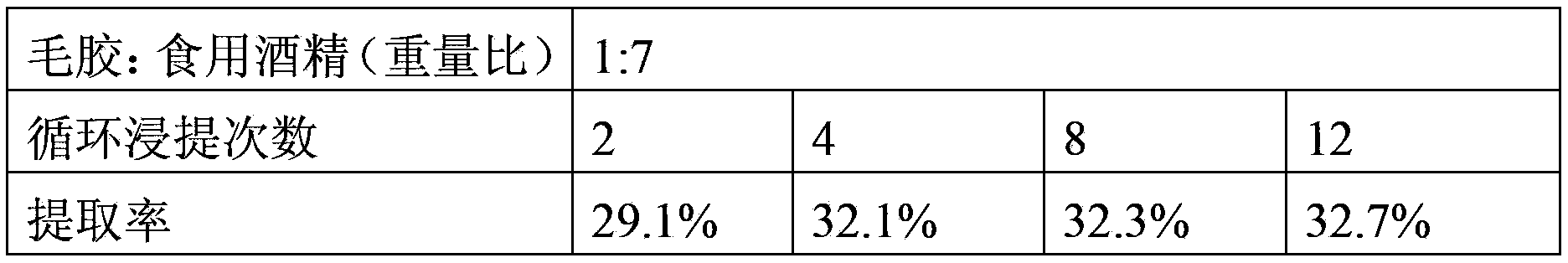

[0040] (2) Loop extraction

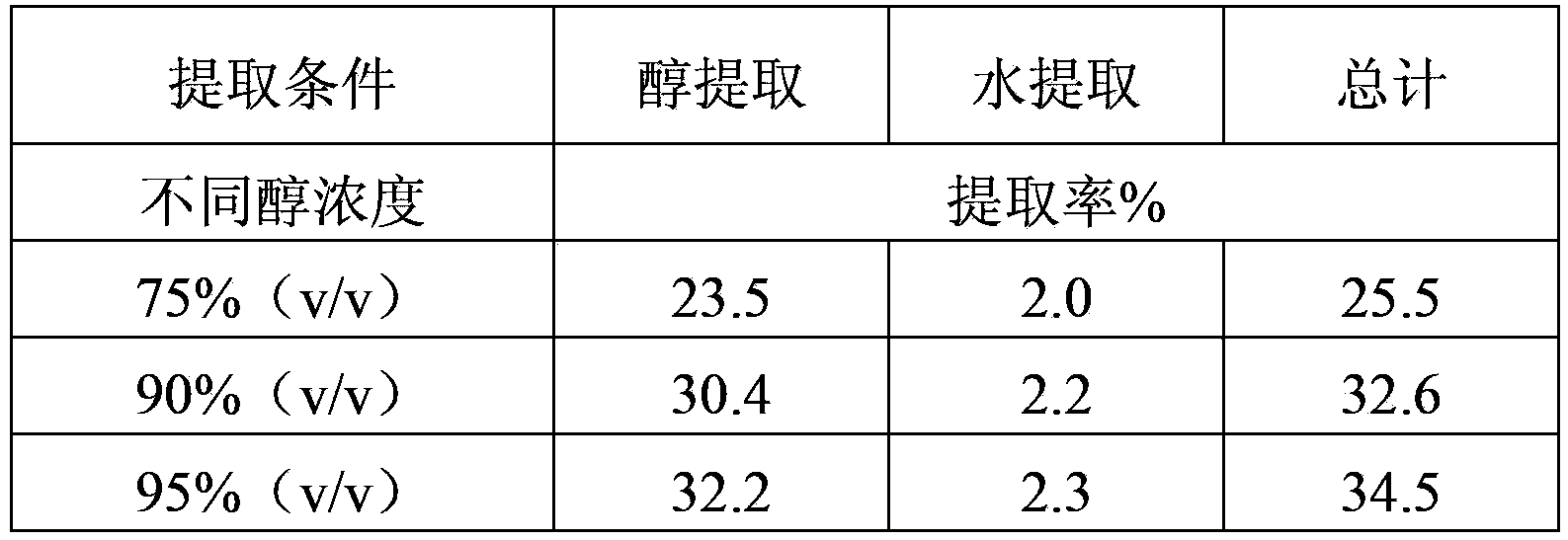

[0041] At 20°C, add 700kg of 90% (v / v) edible alcohol to the above rubber particles as the first extraction solution, mix and stir in the reaction kettle for 24 hours, let stand for 6 hours, and take the supernatant as one time The extract is filtered through a 100-mesh filter and pumped into a mixing tank for use.

[0042] Put 700kg of 95% (v / v) edible alcohol into the reaction kettle containing the remaining materials, mechanically mix and stir in the reaction kettle for 24 hours at 20°C, and let it stand for 6 hours to take the supernatant as the second extraction , by the above-mentioned same method, in the second batch of pulverized 100kg wool gum particles, add the extr...

Embodiment 2

[0060] (1) Low-temperature crushing and sieving

[0061] Put 100kg of wool gum purchased from a beekeeping cooperative into a low-temperature pulverizer, pulverize at -10°C to 30-mesh particles, and pass through a 20-mesh stainless steel screen to obtain hair glue particles.

[0062] (2) Loop extraction

[0063] At 20°C, mix 700kg, 85% (v / v) edible alcohol and (1) fur rubber particles in the reaction kettle for 24 hours and let it stand for 6 hours. After being filtered through the mesh filter, it is pumped into the mixing tank for use.

[0064] Put 700kg of 95% (v / v) edible alcohol into the reaction kettle containing the remaining materials, mechanically mix and stir in the reaction kettle for 24 hours at 20°C, and let it stand for 6 hours to take the supernatant as the second extraction , by the above-mentioned same method, in the second batch of pulverized 100kg wool gum particles, add the extracting solution for the second time as the first extraction and extract, and th...

Embodiment 3

[0073] (1) Low-temperature crushing and sieving

[0074] Put 100kg of wool gum purchased from a beekeeping cooperative into a low-temperature pulverizer, pulverize at -10°C to 30-mesh particles, and pass through a 20-mesh stainless steel screen to obtain hair glue particles.

[0075] (2) Loop extraction

[0076] At 20°C, mix 700kg, 95% (v / v) edible alcohol and fur rubber particles in the reaction kettle for 24 hours, let it stand for 2 hours, take the supernatant, which is the extract, and filter it through a 100-mesh filter Then pump it into the mixing tank for use.

[0077] Put 700kg of 95% (v / v) edible alcohol into the reaction kettle containing the remaining materials, mechanically mix and stir in the reaction kettle for 24 hours at 20°C, and let it stand for 6 hours to take the supernatant as the second extraction , by the above-mentioned same method, in the second batch of pulverized 100kg wool gum particles, add the extracting solution for the second time as the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com