Medium-speed coal mill with double-inlet structure

A double-entry coal pulverizer technology, applied in the field of medium-speed coal pulverizers, can solve the problems of insufficient unit variable load rate, ineffective effect, and no quantitative data support, so as to maintain uniform flow distribution, improve economic performance, Improve the effect of flow field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

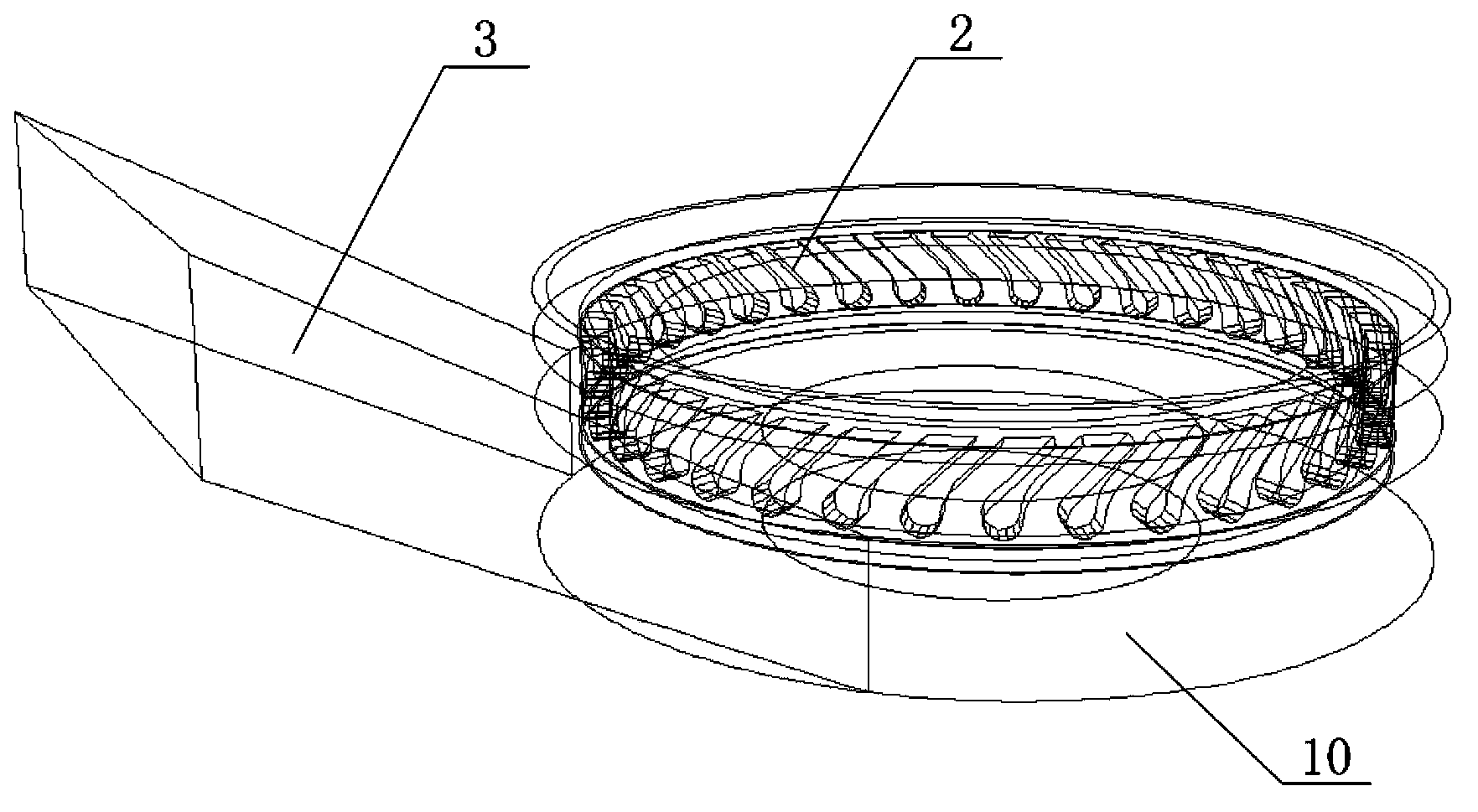

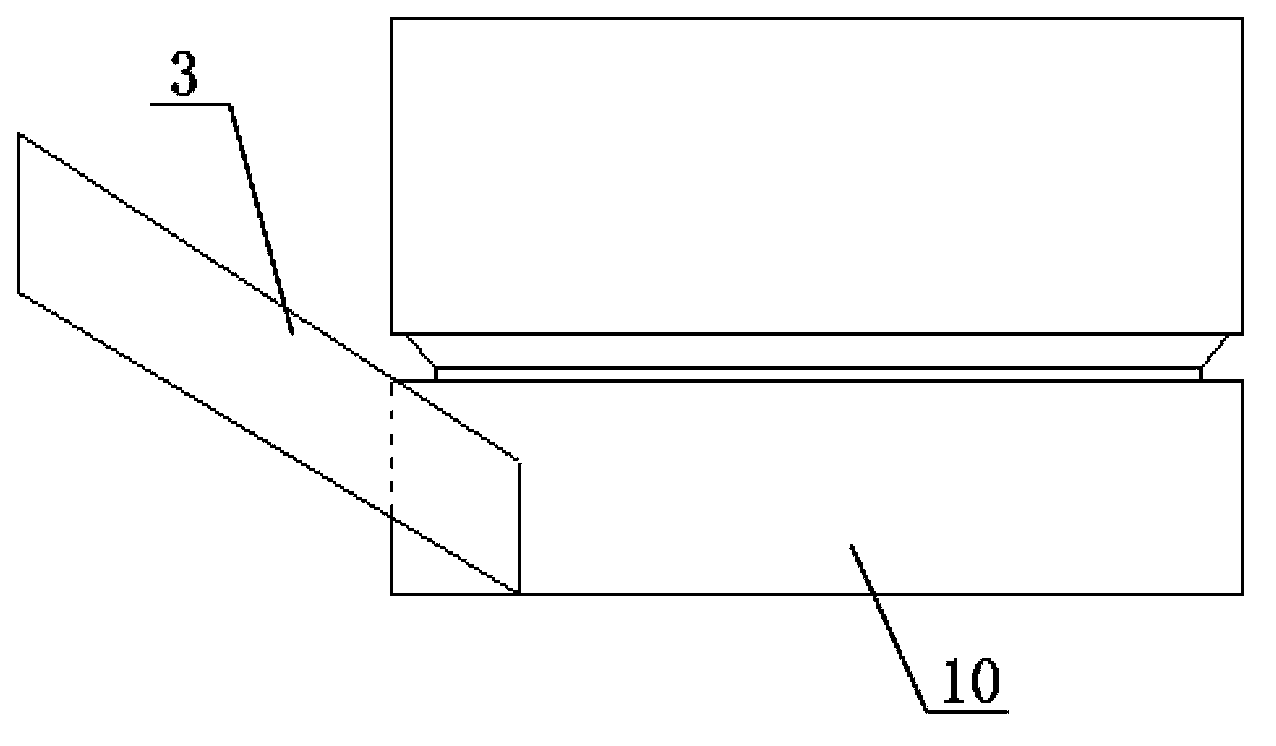

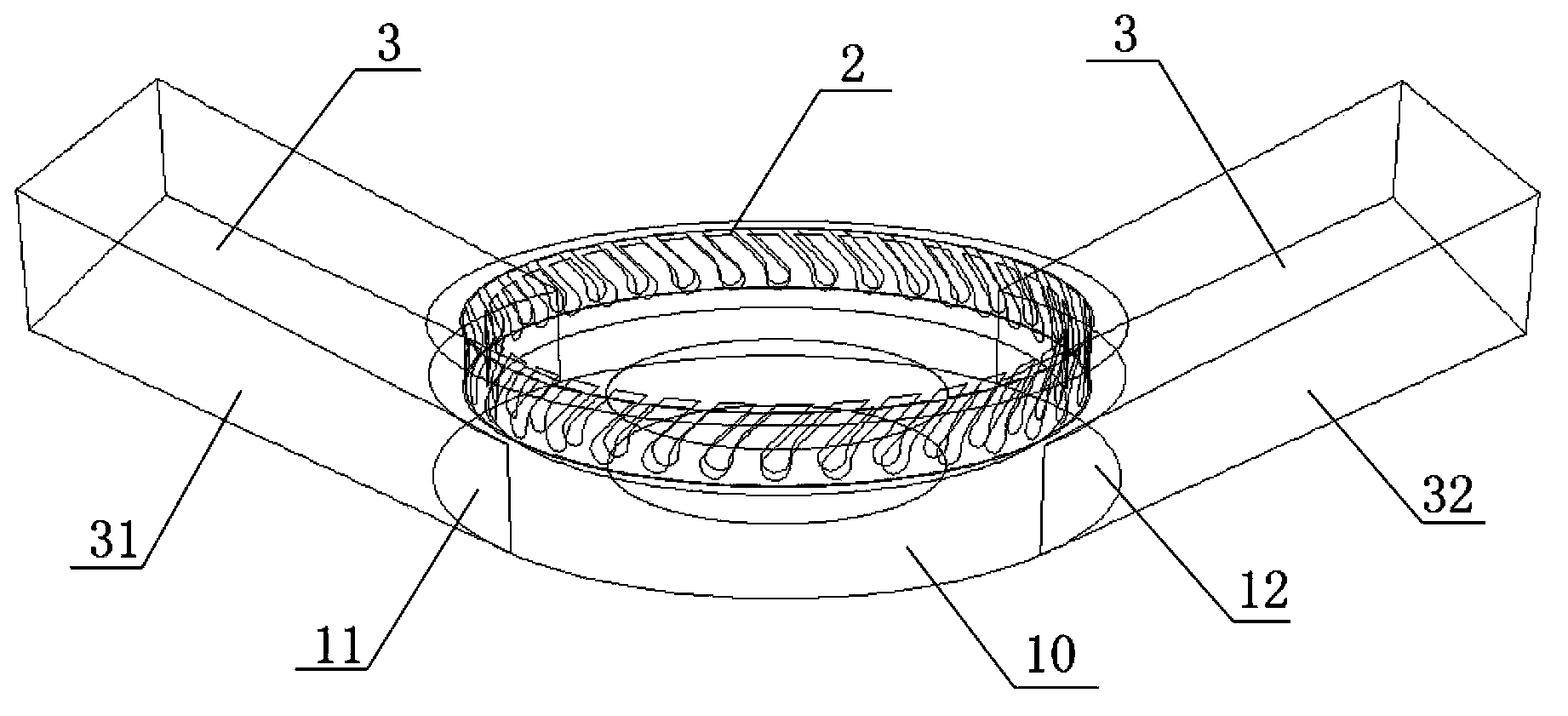

[0029] Please refer to image 3 , Figure 4 , are respectively the three-dimensional structure schematic diagram and the front view structure schematic diagram of Embodiment 1 of the medium-speed coal pulverizer with double inlet structure of the present invention. like image 3 , Figure 4 As shown, in the medium-speed coal mill with double inlet structure of the present invention, an air ring 2 is installed above the air inlet at the bottom 10 of the medium-speed coal mill, and symmetrically arranged on both sides of the bottom 10 of the medium-speed coal mill. There are air inlets 11 and 12, and the air inlets 11 and 12 communicate with the circulation space on the upper part of the medium-speed coal mill. The two air inlets 11, 12 are respectively symmetrically inserted with air inlet troughs 31, 32 having air inlet channels 3, the air inlet troughs 31 and the air inlet troughs 32 are arranged symmetrically, the air inlet troughs 31, 32 The bottom surface of the medium...

Embodiment 2

[0031] As another preferred embodiment of the present invention, please refer to Figure 5 , Image 6 , are respectively the three-dimensional structure schematic diagram and the front view structure schematic diagram of Embodiment 2 of the medium-speed coal pulverizer with double inlet structure of the present invention. In this embodiment, components that are the same as those in Embodiment 1 use the same reference numerals.

[0032] like Figure 5 , Image 6 As shown, in the medium-speed coal mill with double inlet structure of the present invention, an air ring 2 is installed above the air inlet at the bottom 10 of the medium-speed coal mill, and symmetrically arranged on both sides of the bottom 10 of the medium-speed coal mill. There are air inlets 11 and 12, and air inlet troughs 31 and 32 with air inlets 3 are inserted symmetrically on the two air inlets 11 and 12 respectively, and the air inlet troughs 31 and 32 are arranged symmetrically. Wherein, the air inlet g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com