A cold extrusion molding die for power battery aluminum case and molding method thereof

A power battery and forming method technology, applied in the direction of metal extrusion dies, etc., can solve the problems of low operating safety factor, long process, low production efficiency, etc., and achieve the effects of reducing manufacturing costs, dense grain structure, and good plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are only used to illustrate the present invention, but not to limit the protection scope of the present invention.

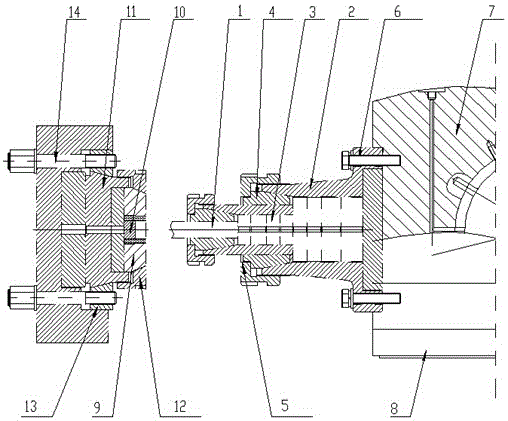

[0018] figure 1 As shown in , a power battery aluminum shell of the present invention is formed by cold extrusion. The mold is divided into two parts: an upper mold and a lower mold. Tight sleeve 4, clamping nut 5 and fixing bolt 6, the lower mold part includes lower mold 9, cushion head 10, die base 11, die nut 12, 4 clamping blocks 13 and 4 bolts 14, the upper die punches The rod 1 is installed on the front side of the upper die base 2, and the spacer 3 is used to adjust the distance in the middle. The clamping sleeve 4 clamps the upper die punch rod, and the clamp nut 5 clamps the upper die punch rod and installs it on the upper die base. 2, the upper mold base 2 is installed and fixed on the front end of the slider 7 through the fixing bolt 6, and the slider 7 is set on the guide rail 8; the lower mold 9 is installed in the die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com