Feed device, machine tool using the feed device and processing method thereof

A technology of feeding device and moving device, applied in the direction of driving device, feeding device, metal processing equipment, etc., can solve problems such as reducing processing efficiency, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

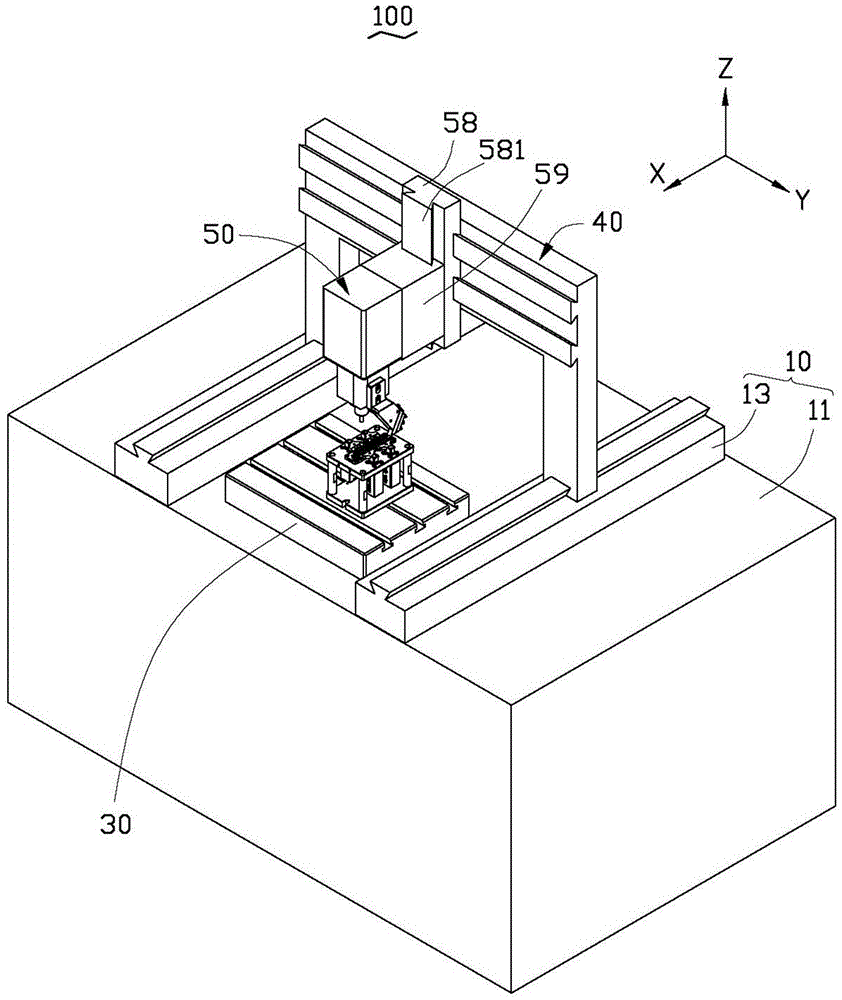

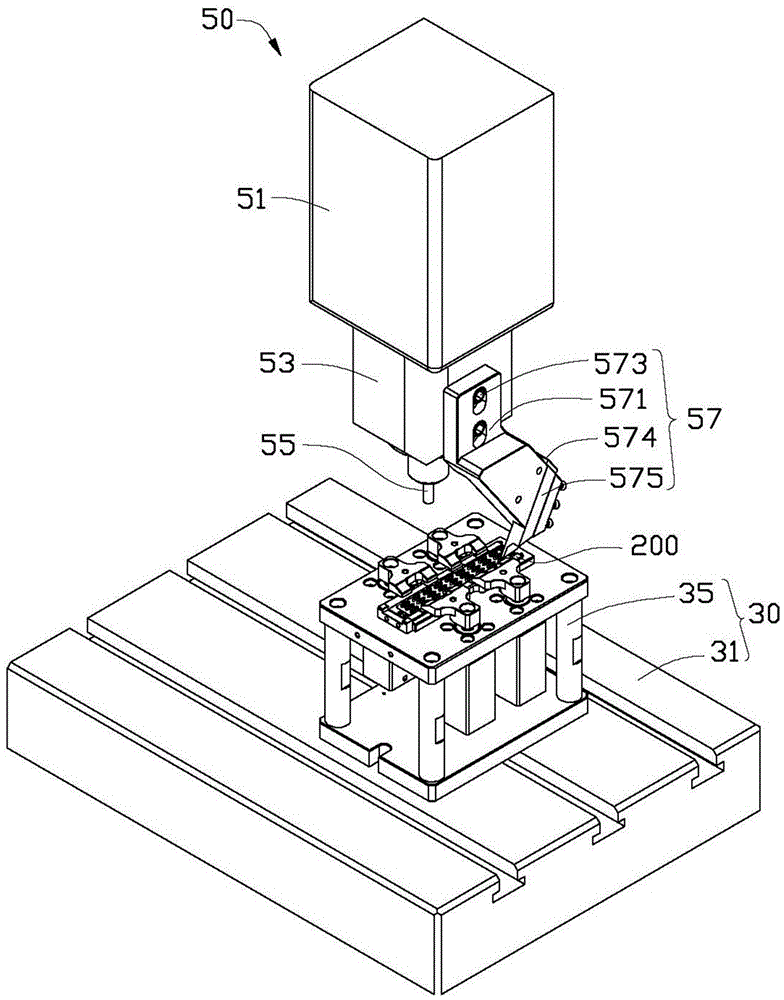

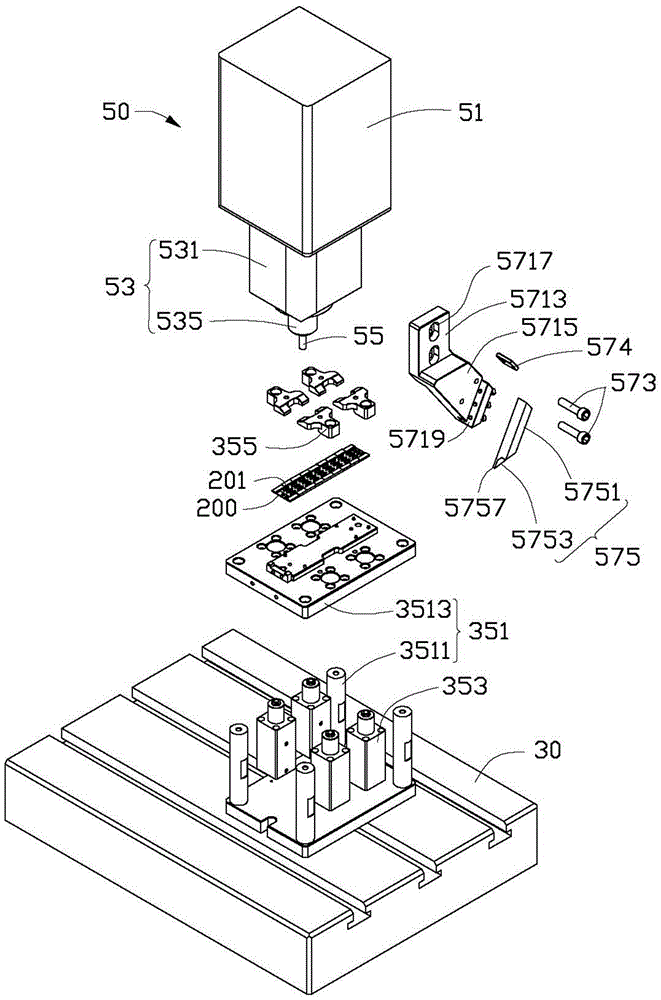

[0021] see figure 1 and figure 2 , the machine tool 100 according to the first embodiment of the present invention is used to perform combined milling and planing processing on a workpiece 200 . The machine tool 100 includes a machine table 10 , a table 30 , a moving device 40 and a feeding device 50 . The workbench 30 is arranged on the machine platform 10, the mobile device 40 is movably installed on the machine platform 10 along the first direction X, and the feeding device 50 is installed on the mobile device 40 and can move relative to the mobile device 40 along the second direction Y and slide in the third direction Z. Certainly, the machine tool 100 also includes other structures such as a controller, such as a driving device for driving the moving device 40 to move. In this embodiment, in order to save space, the description of other structures is omitted, and the omitted part does not affect the technical solution of the present invention.

[0022] Please combine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com