Method of repairing a pedestal surface

a pedestal and surface technology, applied in the field of pedestal surface repair, can solve the problems of leakage and something to be done, pedestal replacement at great expense, and take between two to three man-hours to repair a single pedestal, and achieve the effect of improving the pedestal repair process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The inventors have therefore sought a way of repairing the surface of the pedestal to remove the distortion, coatings or scratches to the top surface of the pedestal. They have developed a method as is now described.

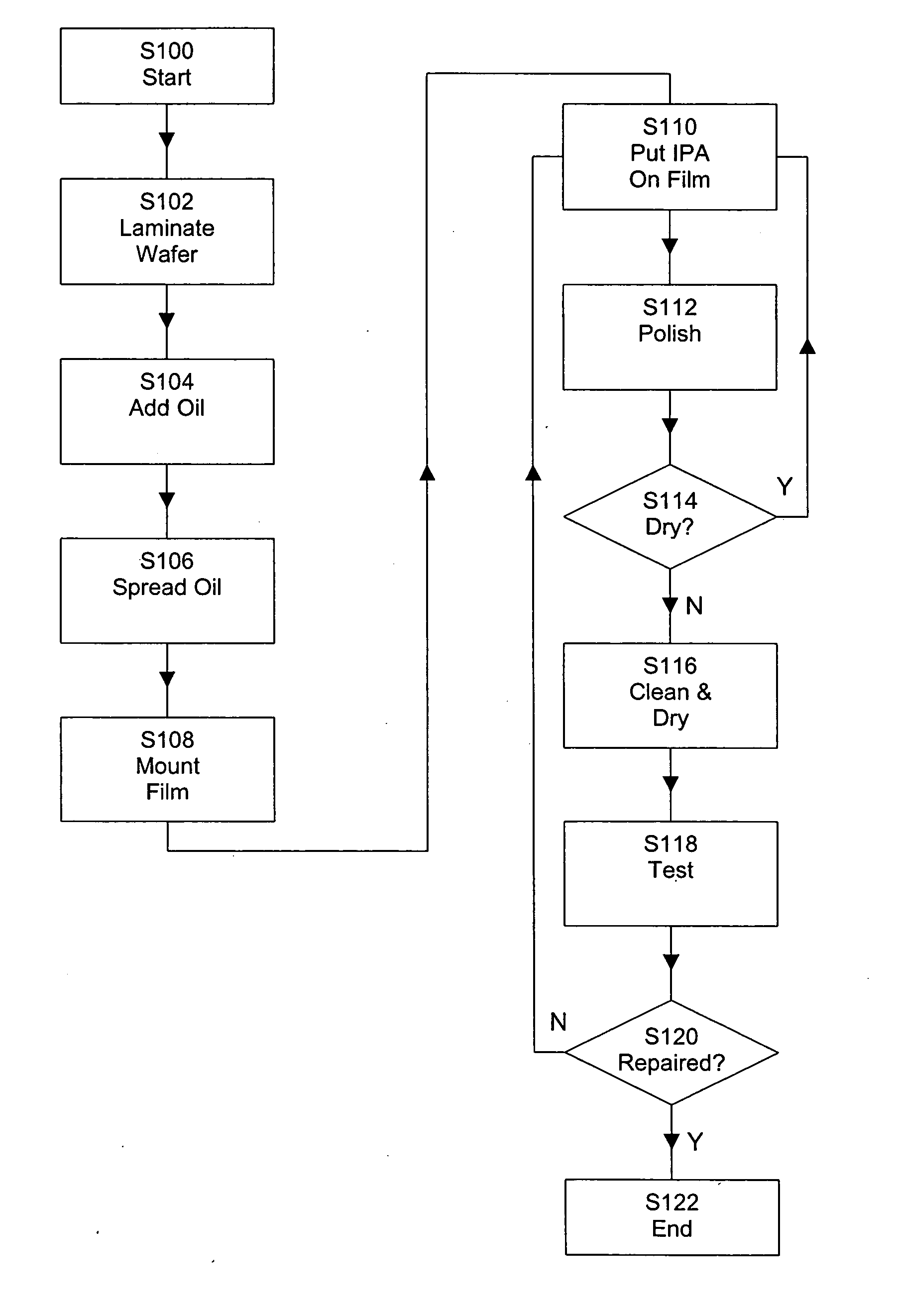

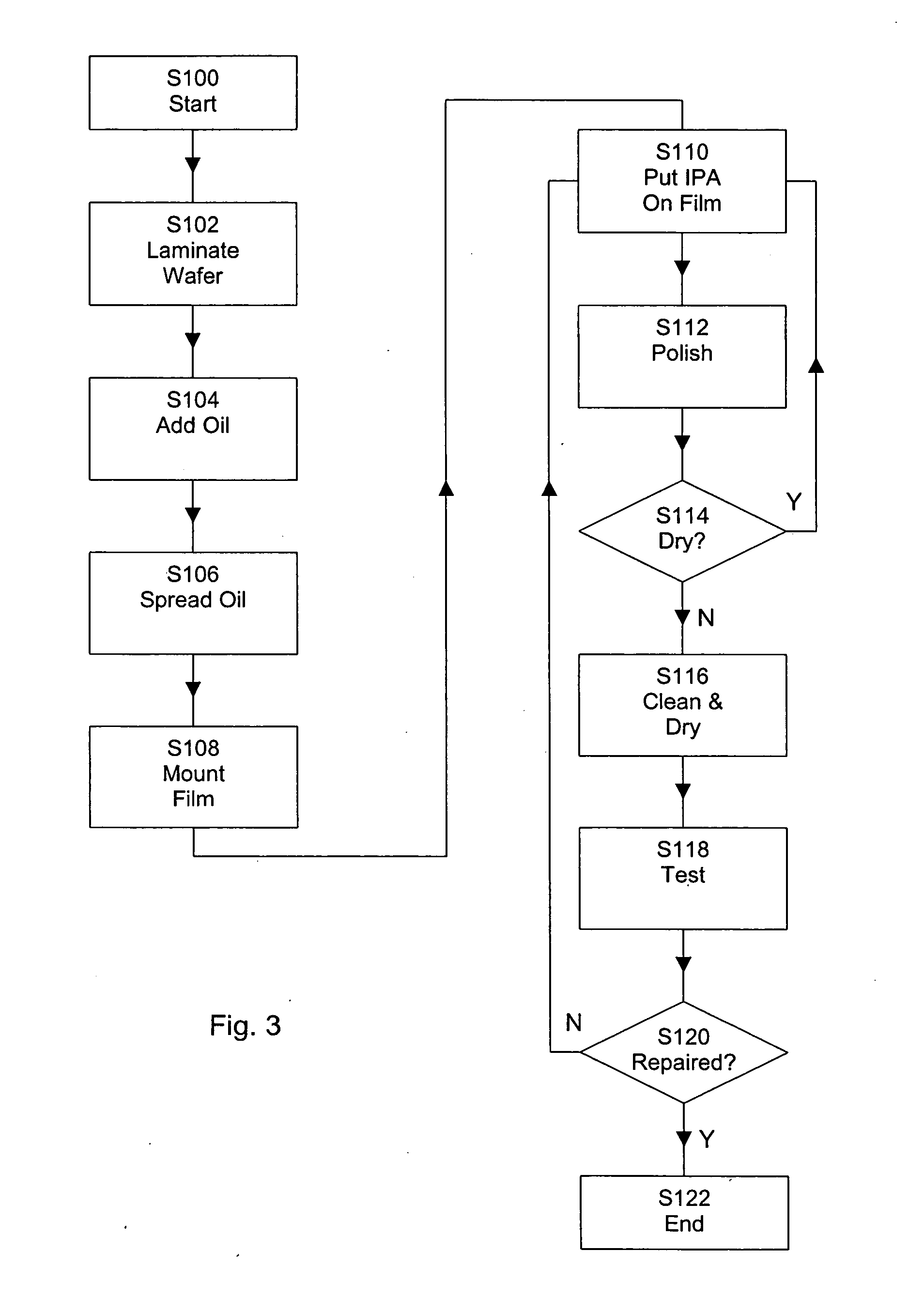

[0022] Firstly a polisher is prepared. At the start (S100), this involves laminating tape onto one surface of a wafer (S102), preferably the shining surface, the wafer ideally being blank. A plastic polymer tape will suffice. Silicon wafers break easily during the polishing process. This tape is used to hold up loose wafer chips when breakage occurs (reducing the number of particles). It can also prevent accidental cuts to a user's fingers as well as providing an improved grip.

[0023] A mineral oil is applied (S104) to the other side of the dummy wafer (that is the side without the tape on it). Preferably this mineral oil should be friendly to semiconductor parts and processes. For instance, the oil could be a fluorinated oil, such as perfluoroalkylether oil. It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com