Method for synthesizing thymalfasin

A new thymus method, -asp technology, applied in the new field of synthetic thymus method, can solve the problems of high production cost, difficult separation and purification, and low total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

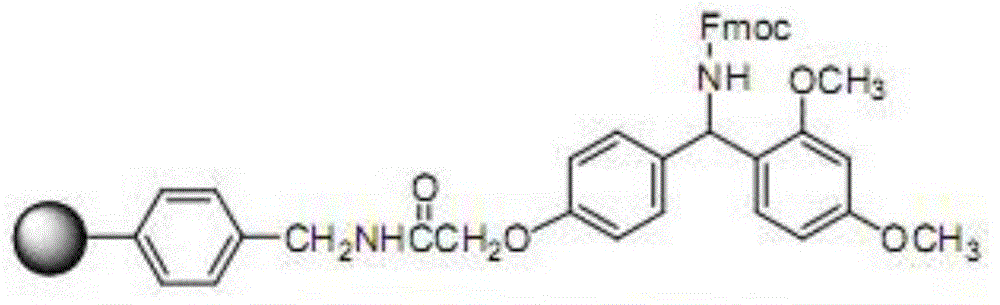

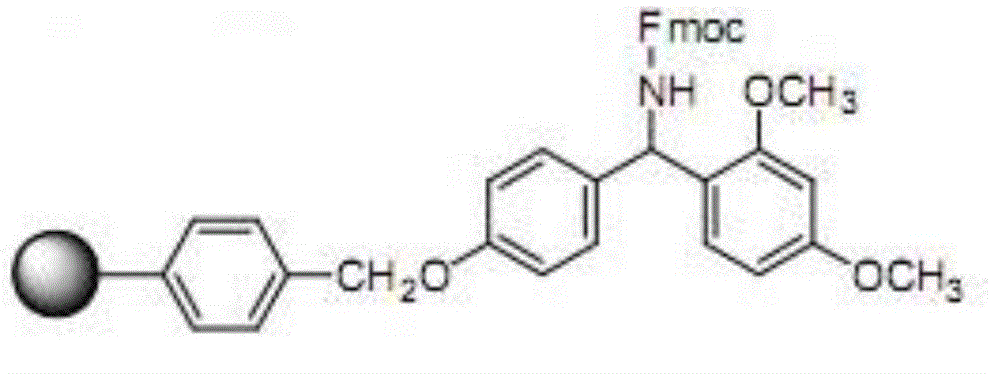

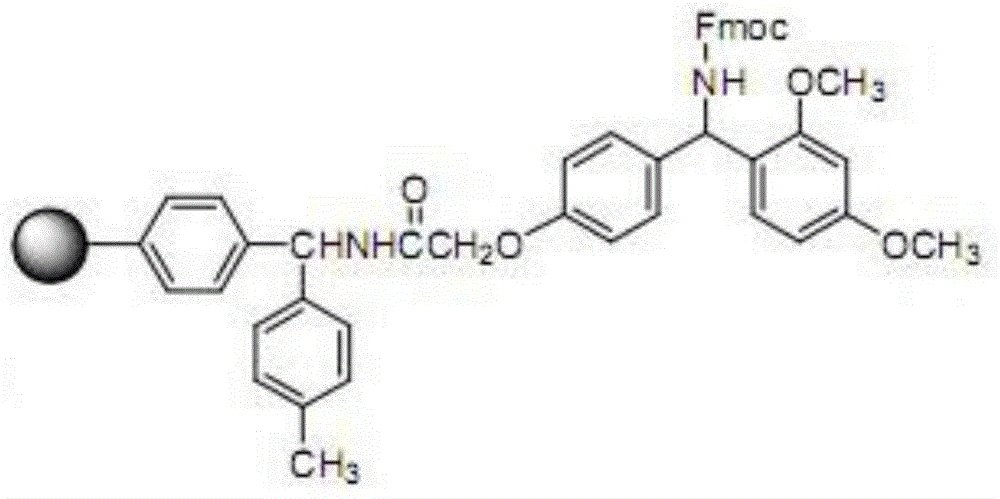

Method used

Image

Examples

Embodiment 1

[0098] Example 1: Synthesis of Polypeptide Fragment 1

[0099] Take by weighing the 2-CTC resin 0.5Kg that substitution degree is 0.6mol / g, join in the solid-phase synthesizer reactor, wash 2 times with DMF, drain after 30 minutes with DMF swelling resin, get 0.6mol Fmoc-Glu ( OtBu)-OH was dissolved in DMF, added to the above-mentioned reaction column equipped with resin, then added 1.2mol DIPEA, dried after 2 hours of reaction, added DMF solution containing 1.2mol of anhydrous methanol, stirred and reacted for 1 hour, washed with DMF 6 times to obtain Fmoc-Glu(OtBu)-2-CTC resin.

[0100] Use 10 mL of 20% piperidine / DMF solution per gram of resin to remove the Fmoc protecting group in the Fmoc-Glu(OtBu)-2-CTC resin for 20 minutes, then wash 6 times with DMF to obtain H-Glu(OtBu)-2-CTC resin.

[0101] Take 0.9mol Fmoc-Lys(Boc)-OH and 0.9mol HOBt, dissolve with DMF, add 0.9mol DIC under stirring, continue to stir and react for 1 hour, add to the reactor of solid-phase synthesi...

Embodiment 2

[0106] Embodiment 2: the synthesis of polypeptide fragment 1

[0107] Take by weighing the 2-CTC resin 0.5Kg that substitution degree is 0.6mol / g, join in the solid-phase synthesizer reactor, wash 2 times with DMF, drain after 30 minutes with DMF swelling resin, get 0.6mol Fmoc-Glu ( OtBu)-OH was dissolved in DMF, added to the above-mentioned reaction column equipped with resin, then added 1.2mol DIPEA, dried after 2 hours of reaction, added DMF solution containing 1.2mol of anhydrous methanol, stirred and reacted for 1 hour, washed with DMF 6 times to obtain Fmoc-Glu(OtBu)-2-CTC resin.

[0108] Use 10 mL of 20% piperidine / DMF solution per gram of resin to remove the Fmoc protecting group in the Fmoc-Glu(OtBu)-2-CTC resin for 20 minutes, then wash 6 times with DMF to obtain H-Glu(OtBu)-2-CTC resin.

[0109] Take 0.9mol Fmoc-Lys(Boc)-OH and 0.9mol HOBt, dissolve in DMF, add 0.86mol HBTU under stirring, continue to stir for 1 hour, then add 1.3mol DIPEA, mix well and add to th...

Embodiment 3

[0114] Embodiment 3: the synthesis of polypeptide fragment 2

[0115] Weigh 0.2Kg of Rink MBHA resin with a degree of substitution of 0.5mol / g, add it to the reactor of a solid-phase synthesizer, wash it twice with DMF, swell the resin with DMF for 30 minutes, and drain it, and use 10mL of 20% piperidine per gram of resin / DMF solution to remove the Fmoc protecting group in the resin for 20 minutes, and then wash 6 times with DMF to obtain the deprotected Rink MBHA resin.

[0116] Take 0.3mol Asp(α-OtBu)-OH and 0.3mol HOBt, dissolve with DMF, add 0.3mol DIC under stirring, continue to stir and react for 1 hour, add it to the reactor of solid-phase synthesizer, and react at room temperature for 2h (reaction end point is indene The triketone method is used for detection, if the resin is colorless and transparent, the reaction is complete, and the resin develops color, indicating that the reaction is incomplete, and the coupling reaction time needs to be prolonged) to obtain Fmoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com