A kind of colorful ultra-thin rock flake synthetic water-in-water colorful paint and its production process

A colorful paint, a colorful technology, applied in the field of paint application, can solve the problems of easy breakage of water-in-water ideas, construction colors, and easy destruction of water-in-water watercolor spots, etc., and achieve excellent water resistance and water whitening resistance, particle size, etc. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

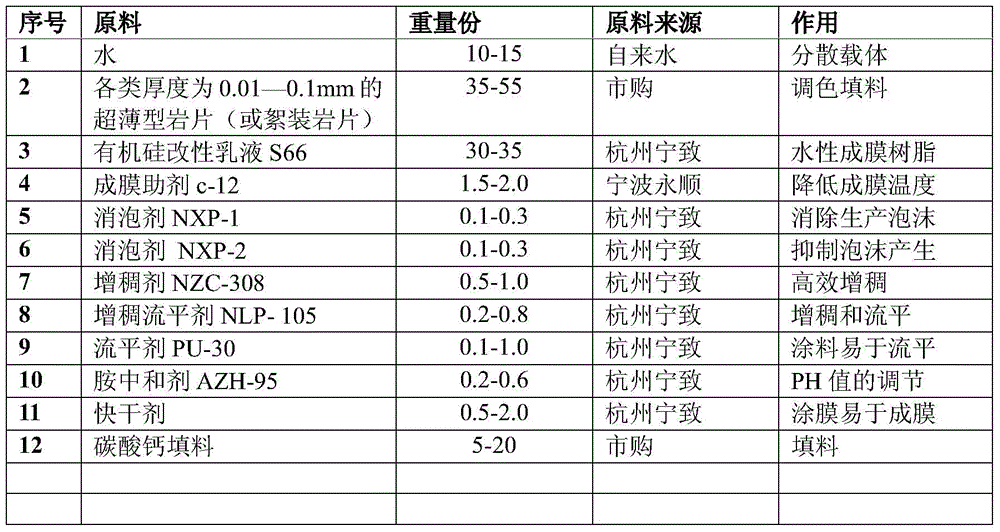

[0037] Embodiment 1: this multicolored ultra-thin rock flake of the present invention synthesizes water-in-water multicolored paint (marble: Chinese black), and each raw material is as follows according to the proportioning of weight: 10 parts of water, thickness are 0.01-0.1mm super Thin rock slices: 35 parts (15 parts of black flocculent rock flakes, 20 parts of white flocculent rock flakes), silicone modified emulsion S66: 30 parts, film-forming aid c-12: 1.5 parts, defoamer NXP-1: 0.1 part, defoamer NXP-2: 0.1 part, thickener NZC-308: 0.5 part, leveling thickener NLP-105: 0.2 part, leveling agent PU-30: 0.1 part, amine neutralizer AZH -95: 0.2 parts, 0.5 parts of quick-drying agent, 5 parts of calcium carbonate filler. The quick-drying agent is prepared by proportioning the following raw materials according to parts by weight: 40 parts of ethanol, 30 parts of dimethyl carbonate, and 5 parts of propylene glycol butyl ether.

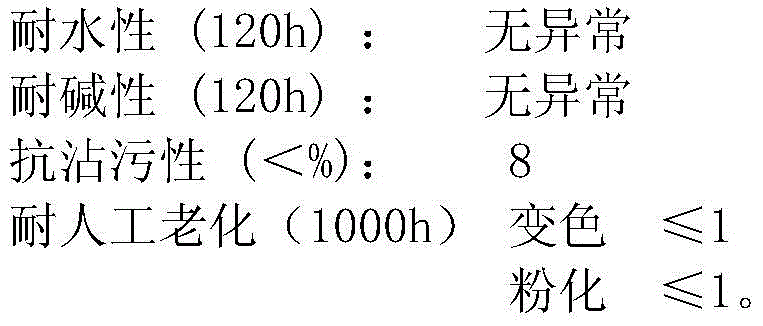

[0038] Performance:

[0039]

Embodiment 2

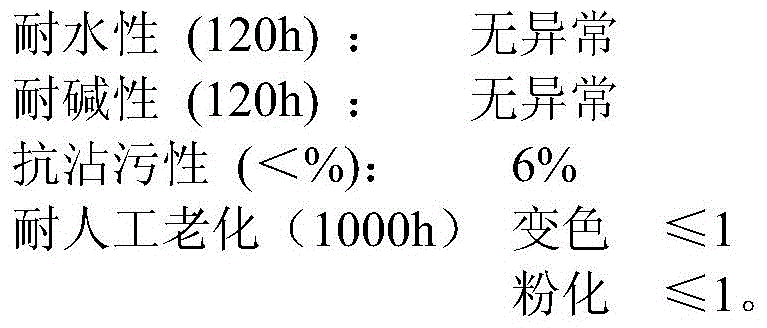

[0040] Embodiment 2: this colorful ultra-thin rock flakes of the present invention synthesizes water-in-water multicolored coatings, each raw material is as follows according to weight ratio: 15 parts of water, the ultrathin rock flakes that thickness is 0.01-0.1mm: 55 parts, Silicone modified emulsion S66: 35 parts, coalescent c-12: 2.0 parts, defoamer NXP-1: 0.3 parts, defoamer NXP-2: 0.3 parts, thickener NZC-308: 1.0 parts , Leveling thickener NLP-105: 0.8 parts, leveling agent PU-30: 1.0 parts, amine neutralizer AZH-95: 0.6 parts, quick-drying agent 2.0 parts, calcium carbonate filler 20 parts. The quick-drying agent is prepared by proportioning the following raw materials in parts by weight: 60 parts of ethanol, 50 parts of dimethyl carbonate, and 15 parts of propylene glycol butyl ether.

Embodiment 3

[0041] Embodiment 3: this colorful ultra-thin type rock flakes of the present invention synthesizes water-in-water multicolored coatings, each raw material is as follows according to weight ratio: water 12 parts, thickness is the ultrathin rock flakes of 0.01-0.1mm: 40 parts, Silicone modified emulsion S66: 32 parts, film-forming aid c-12: 1.8 parts, defoamer NXP-1: 0.2 parts, defoamer NXP-2: 0.2 parts, thickener NZC-308: 0.8 parts , Leveling thickener NLP-105: 0.5 parts, leveling agent PU-30: 0.5 parts, amine neutralizer AZH-95: 0.4 parts, quick-drying agent 1.0 parts, calcium carbonate filler 15 parts. The quick-drying agent is prepared by proportioning the following raw materials according to parts by weight: 50 parts of ethanol, 40 parts of dimethyl carbonate, and 10 parts of propylene glycol butyl ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com