Wind power generator gearbox damper and damping protection method thereof

A technology for wind turbines and gearboxes, which is applied to wind turbine components, wind turbines, shock absorbers, etc., to achieve the effect of good vibration reduction and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

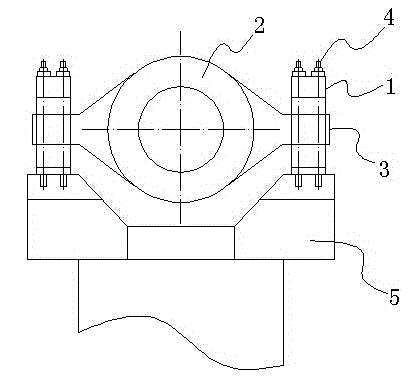

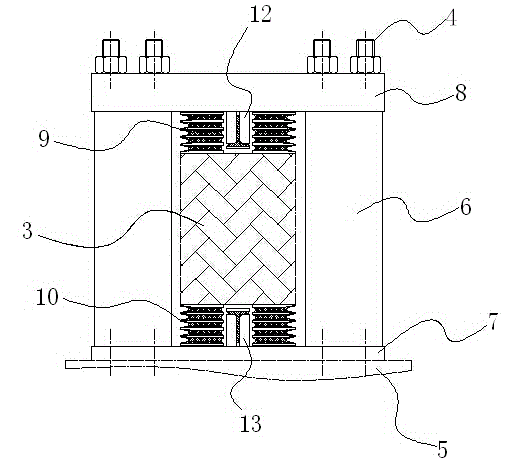

[0047] Embodiment 1: as figure 2 As shown, a wind turbine gearbox shock absorber 1 includes a main frame, and the main frame includes support columns 6 on both sides, a backing plate 7 arranged at one end of the support columns 6 on both sides, and a backing plate 7 arranged on the The beam 8 at the other end of the support column 6 on both sides; the upper laminated spring 9 and the lower laminated spring 10, which are respectively arranged on the opposite surfaces of the beam 8 and the backing plate 7; the screw rod 4 passes through the The crossbeam 8, the support columns 6 on both sides, the backing plate 7 and the generator set main frame 5 are connected to the generator set main frame 5, and the upper laminated spring 9 and the lower laminated spring 10 are both opened. There is a cavity 11, and the wind power generator gearbox shock absorber 1 also includes an upper buffer pad 12 and a lower buffer pad 13, which are respectively arranged on the opposite surfaces of ...

Embodiment 2

[0056] Embodiment 2: as Figure 7 As shown, compared with Embodiment 1, the wind turbine gearbox damper in this embodiment is different in that: the cavities 11 of the upper laminated spring 9 and the lower laminated spring 10 are blind holes One end of the upper buffer pad 12 and the lower buffer pad 13 is respectively arranged on the opposite surface of the crossbeam 8 and the backing plate 7 by screws, and the other end is connected with the hollow space of the upper laminated spring and the lower laminated spring respectively. There is a gap 20 at the bottom of the cavity 11, and the gap 20 here can also be designed according to actual working conditions. In this way, the rigidity of the laminated spring is relatively large, which is suitable for units or working conditions with relatively large rated loads.

[0057] When the load transmitted by the torque arm of the gearbox ≤ the rated load, there is no gap between the top plate 17 of the upper buffer pad and the bottom ...

Embodiment 3

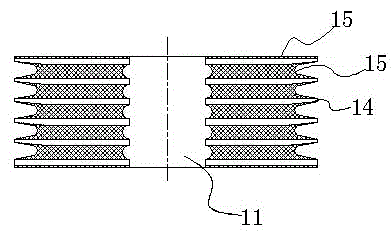

[0062] Embodiment 3: as Figure 8 As shown, compared with Embodiment 2, the wind power generator gearbox shock absorber in this embodiment differs in that: the upper laminated spring 9 and the lower laminated spring 10 are both tapered, and the upper laminated spring 9 The dividing plate 14 in the layer spring 9 and the lower layer spring 10 is a tapered spacer. This structure enables the shock absorber to obtain greater lateral stiffness while having greater vertical stiffness, thereby providing lateral stability of the shock absorber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com