Passive braking system of mining transportation equipment

A technology for transportation equipment and braking systems, applied in mechanical equipment, brake types, brake actuators, etc., can solve the problems of short safe operation time, increased equipment maintenance, troublesome maintenance personnel, etc., to extend safe operation time, The effect of reduced maintenance difficulty and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

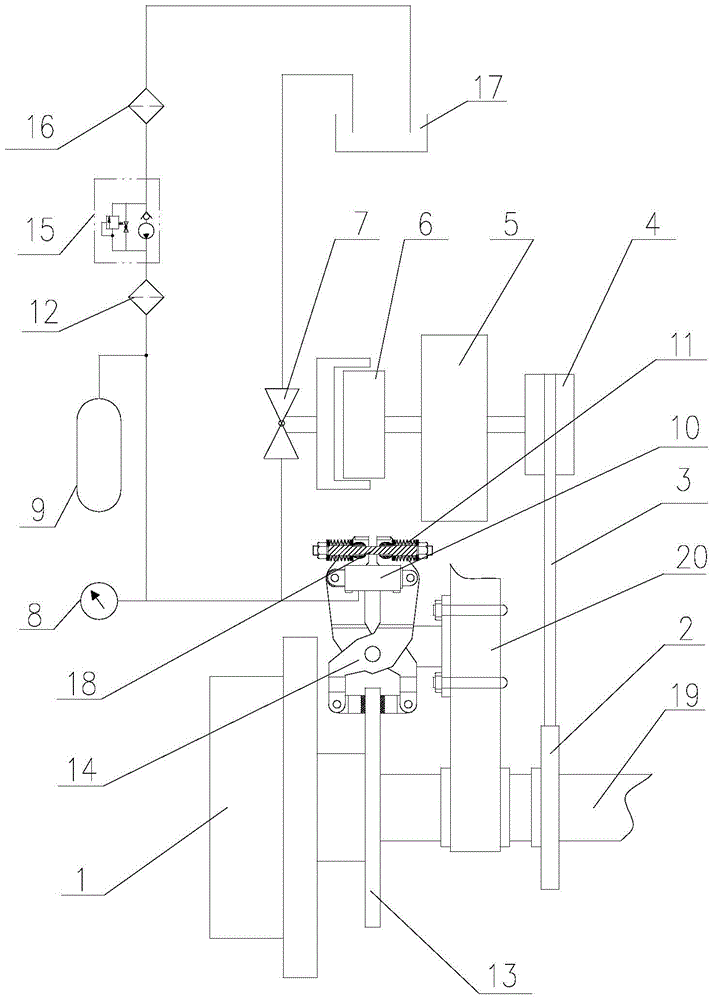

[0009] Such as figure 1 As shown, a passive braking system for mining transportation equipment includes a driving wheel 1, a main sprocket 2 and a brake disc 13 are installed on the driving shaft 19 of the driving wheel 1, and a caliper brake 14 is installed on the vehicle frame 20, the main sprocket 2 is connected to the secondary sprocket 4 through the chain 3, the secondary sprocket 4 is connected to the centrifugal clutch 6 through the speed increaser 5, the centrifugal clutch 6 is connected to the shut-off valve 7, and one end of the shut-off valve 7 is connected to the brake cylinder 10. The other end is connected to the oil tank 17, and the brake cylinder 10 is installed on the handle end of the caliper brake 14, and the final shaft 18 is installed on the handle end of the caliper brake 14, and the disc spring 11 is installed on the final shaft 18; the manual pump 15 The oil inlet pipe is connected to the oil tank 17, the oil outlet pipe is connected to the brake cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com