A fiber grating temperature compensation method and ultra-thin miniature steel bar strain gauge

A fiber grating, temperature compensation technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of increasing the disturbance of the original structure, increasing the volume of the sensor, increasing the disturbance of the original structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

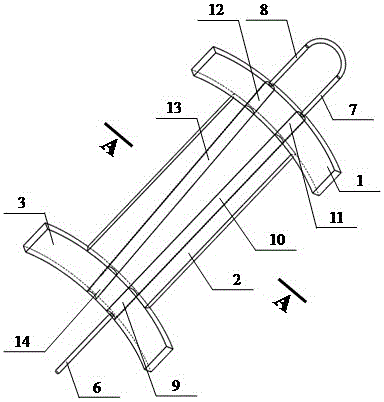

[0044] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0045] An optical fiber grating temperature compensation method and an ultra-thin miniature steel bar strain gauge, including an optical fiber grating temperature compensation method and an optical fiber grating ultrathin miniature steel bar strain gauge;

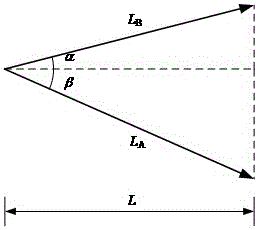

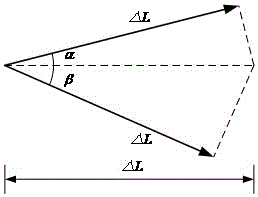

[0046] A fiber grating temperature compensation method, using two fiber gratings, the angle between the axial direction of fiber grating A and the principal strain direction is α, the angle between the axial direction of fiber grating B and the principal strain direction is β, and α and β are desirable It is any value between 0° and 90°, and the absolute values of α and β are not equal.

[0047] Such as figure 1 As shown, take the gauge length parallel to the principal strain direction as L, then within the range of the gauge length, the length L of the fiber grating A A and the length L of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com