Observation method of B-type inclusion behaviors in aluminum killed steel

A technology for aluminum-killed steel and inclusions, applied in the field of metallurgy, can solve the problems of poor control effect of B-type inclusions, difficult to effectively observe the formation of B-type inclusions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

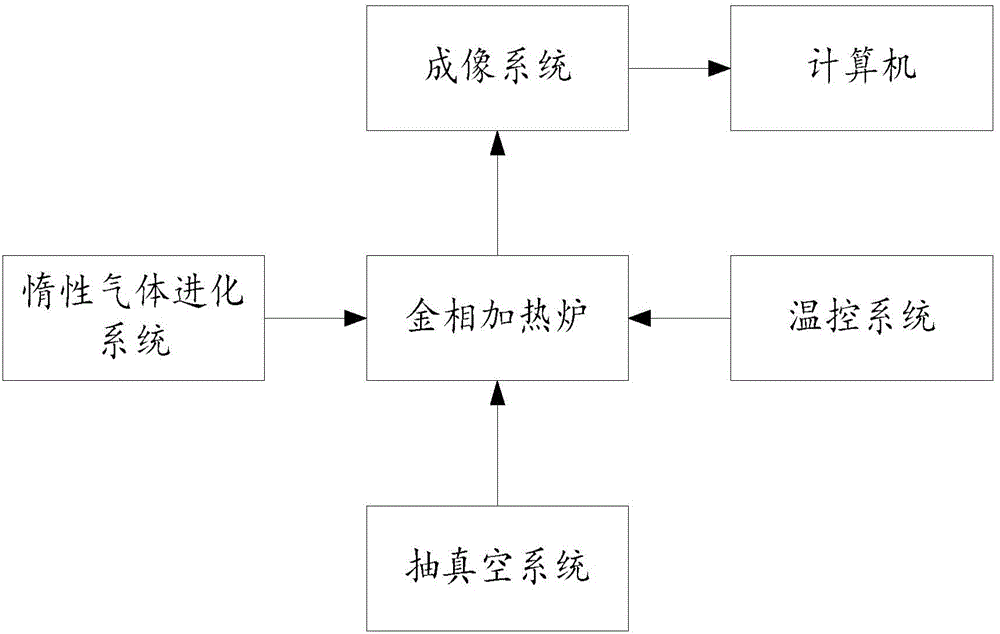

[0016] see figure 1 , The high-temperature laser confocal microscope includes: imaging system, vacuum system, inert gas purification system, metallographic heating furnace and temperature control system, among which the temperature control system includes R-type thermocouples. The embodiment of the present invention uses a high-temperature laser confocal microscope to observe the behavior of B-type inclusions in aluminum-killed steel.

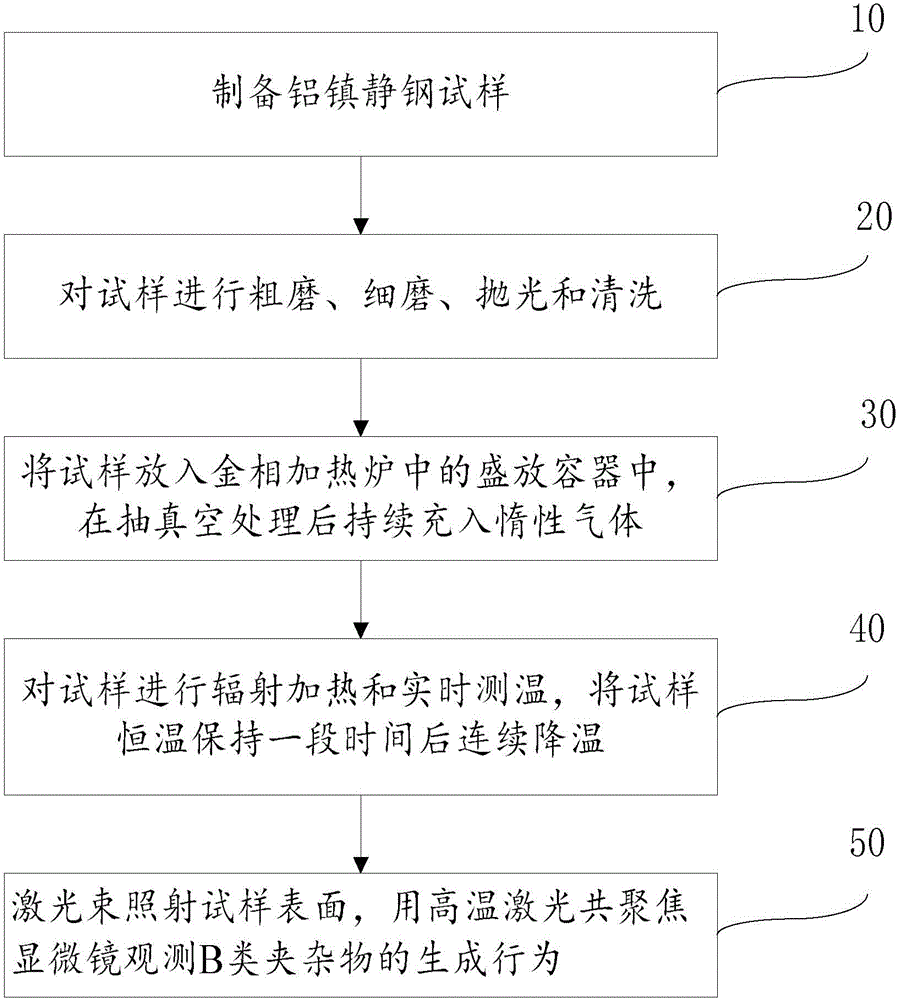

[0017] see figure 2 , a method for observing the behavior of B-type inclusions in aluminum-killed steel provided in an embodiment of the present invention, specifically includes the following steps:

[0018] Step 10: Prepare an aluminum-killed steel sample by wire cutting. The aluminum-killed steel sample is in the shape of a cylinder with a diameter of 6-7.5 mm and a height of 1-3 mm.

[0019] Step 20: Roughly grind and finely grind the surface of the aluminum-killed steel sample, and use a diamond polishing agent to polish the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com