Image processing for AOI (automated optical inspection)-based bullet appearance defect detection system

A defect detection and image processing technology, applied in the field of image processing, can solve the problems of not reflecting information well, difficult for operators, and obtaining information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

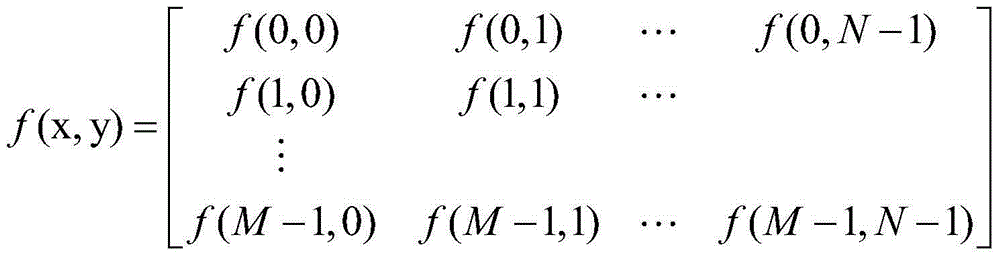

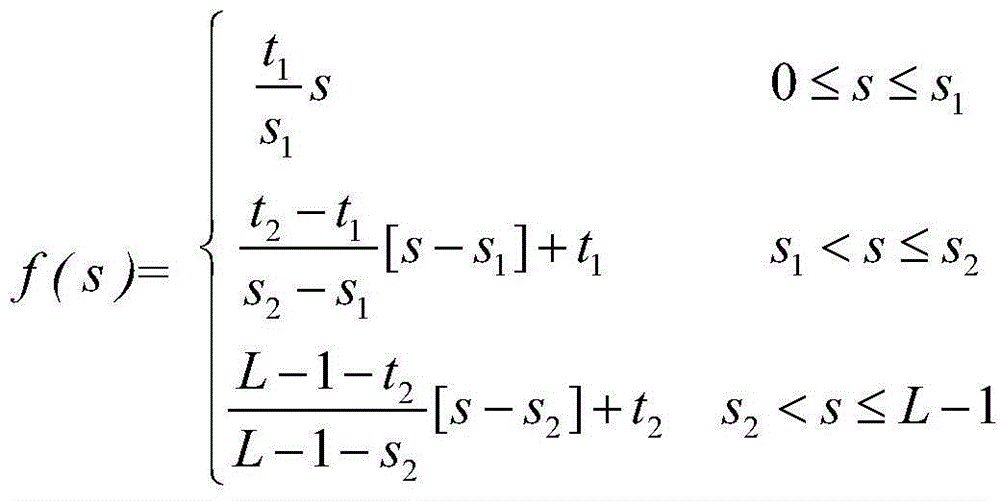

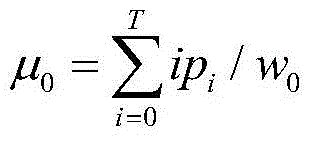

[0034] The image processing algorithm of the AOI-based bullet apparent defect detection system includes the following steps:

[0035] (1) Obtain the original image of the bullet's appearance through the optical imaging module and image acquisition module of the AOI system; this process is relatively mature in AOI technology, and will not be repeated in this embodiment;

[0036] (2) The median filtering method is used to process the original image to remove noise and smooth the original image signal; specifically, the median filtering method is as follows:

[0037] (2a) Determine a neighborhood centered on a certain pixel;

[0038] (2b) Compare the gray value of each pixel in the neighborhood, and take the middle value as the new gray value of the selected pixel;

[0039] (2c) Set the neighborhood as a window, and move the window in sequence according to the filtering method to process the entire image.

[0040] Wherein, the shape of the neighborhood in the step (2a) is a square, and furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com