Method and device for inverter to control over-excitation shutdown of motor

A frequency converter control and over-excitation technology, applied in the field of frequency converters, can solve problems such as commutation failure, high use cost, and complex control, and achieve the effects of improving reliability and operating efficiency, avoiding system failure points, and simple control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

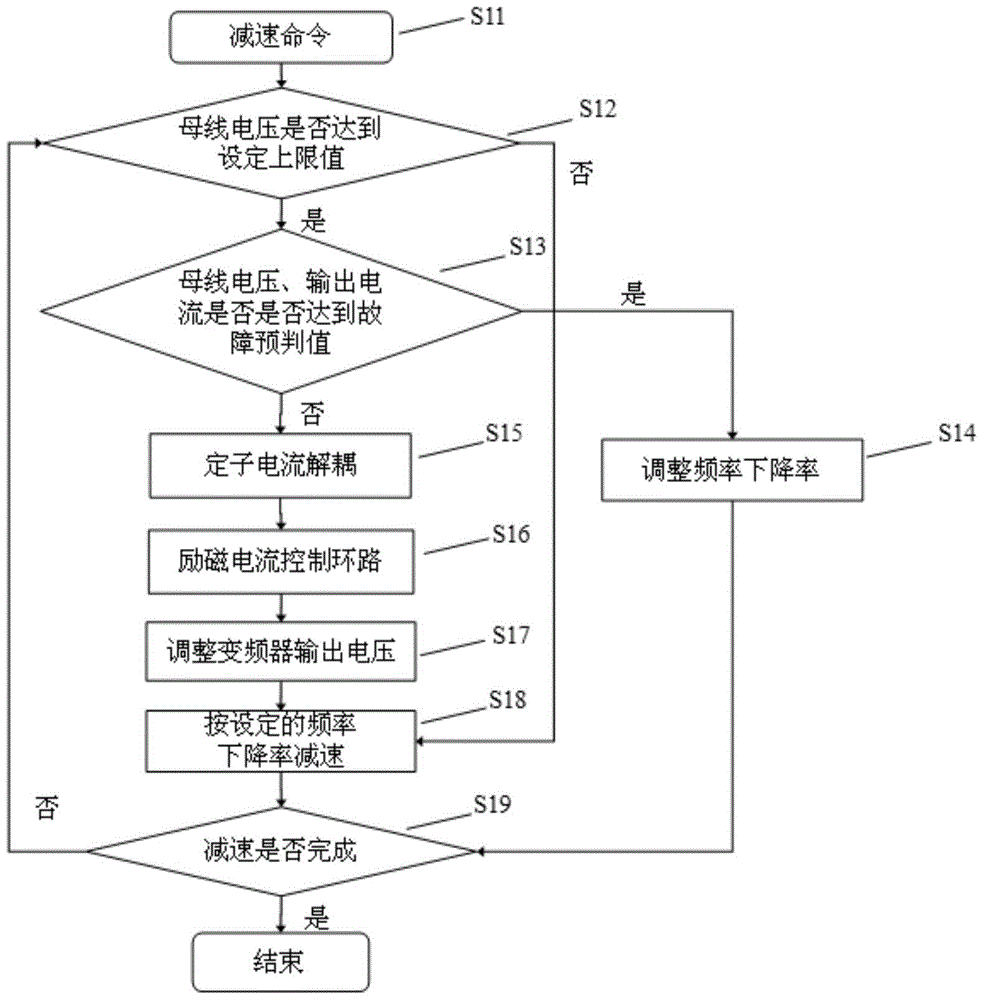

[0043] The present invention utilizes the over-excitation of the motor to stop. When the motor is stopped, if the motor enters the power generation state due to the large rotor inertia, the frequency converter increases the excitation current of the stator to over-excite the motor and convert the excess electric energy into heat energy for consumption. In turn, the motor can be stopped as soon as possible without reporting an overvoltage or overcurrent fault.

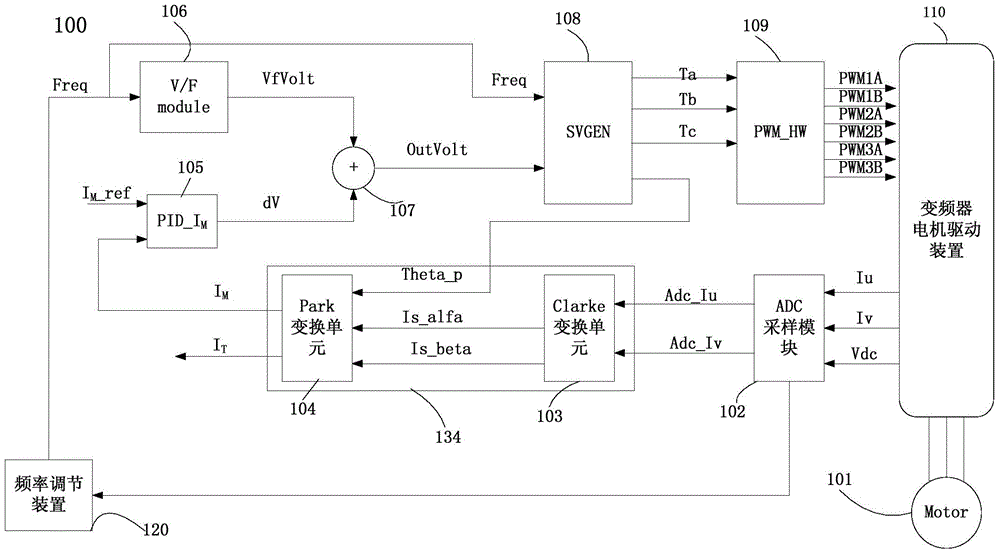

[0044] like figure 1 As shown, the device 100 for frequency converter to control over-excitation shutdown of the present invention includes a frequency converter motor drive device 110, a frequency adjustment device 120, a bus voltage and phase current sampling circuit 102, a stator current decoupling calculation device 134, and an excitation circuit PI regulator 105 , a V / F output voltage calculation device 106 , an adder 107 , a voltage vector calculation module 108 , and a PWM duty cycle calculation module 109 . Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com