Shredded air-dried beef and preparation method thereof

An air-dried beef and hand-shearing technology, which is applied to the field of hand-sheared and air-dried beef and its preparation, can solve the problems of poor taste of air-dried beef, hidden dangers of food safety, low drying efficiency, etc., so as to reduce hidden dangers of food safety, improve drying efficiency, and avoid The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The shredded air-dried beef is obtained according to the following preparation method: the first step is to add appropriate amount of Snow Lotus, Cistanche, Cynomorium Cynomorium, Safflower, Codonopsis Codonopsis, Rhodiola Rosea, Angelica and Lycium barbarum into water and boil it After 2 hours to 3 hours, the seasoning liquid is obtained, wherein: 1 to 2 grams of snow lotus, 1 to 1.5 grams of Cistanche, 3 to 5 grams of Cynomorium, and 1 to 2 grams of safflower are added to each kilogram of water , 2 grams to 4 grams of Codonopsis, 1.5 grams to 3 grams of Rhodiola, 2 grams to 4 grams of Angelica and 3 grams to 5 grams of Lycium barbarum; the second step, in parts by weight, will be 0.5 parts to 1 part of pepper powder, 0.3 to 0.5 parts of star anise powder, 2 to 4 parts of edible salt, 1 to 1.5 parts of white sugar, 2 to 4 parts of chicken essence, 2 to 3 parts of soy sauce and 20 parts 333 parts of the seasoning liquid are mixed to obtain a mixed season...

Embodiment 2

[0022] Embodiment 2: The shredded air-dried beef is obtained according to the following preparation method: the first step is to add appropriate amount of Snow Lotus, Cistanche, Cynomorium Cynomorium, Safflower, Codonopsis Codonopsis, Rhodiola Rosea, Angelica and Lycium barbarum into water and boil and boil After 2 hours or 3 hours, the seasoning liquid is obtained, wherein: 1 gram or 2 grams of snow lotus, 1 gram or 1.5 gram of Cistanche, 3 gram or 5 gram of Cynomorium cynomorium, 1 gram or 2 gram of safflower are added to every kilogram of water , 2 grams or 4 grams of Radix Codonopsis, 1.5 grams or 3 grams of Rhodiola Rosea, 2 grams or 4 grams of Angelica and 3 grams or 5 grams of Lycium barbarum; the second step, by weight parts, will be 0.5 parts or 1 part of pepper powder, 0.3 or 0.5 parts of star anise powder, 2 or 4 parts of edible salt, 1 or 1.5 parts of white sugar, 2 or 4 parts of chicken essence, 2 or 3 parts of soy sauce and 20 parts Or 333 parts of the seasonin...

Embodiment 3

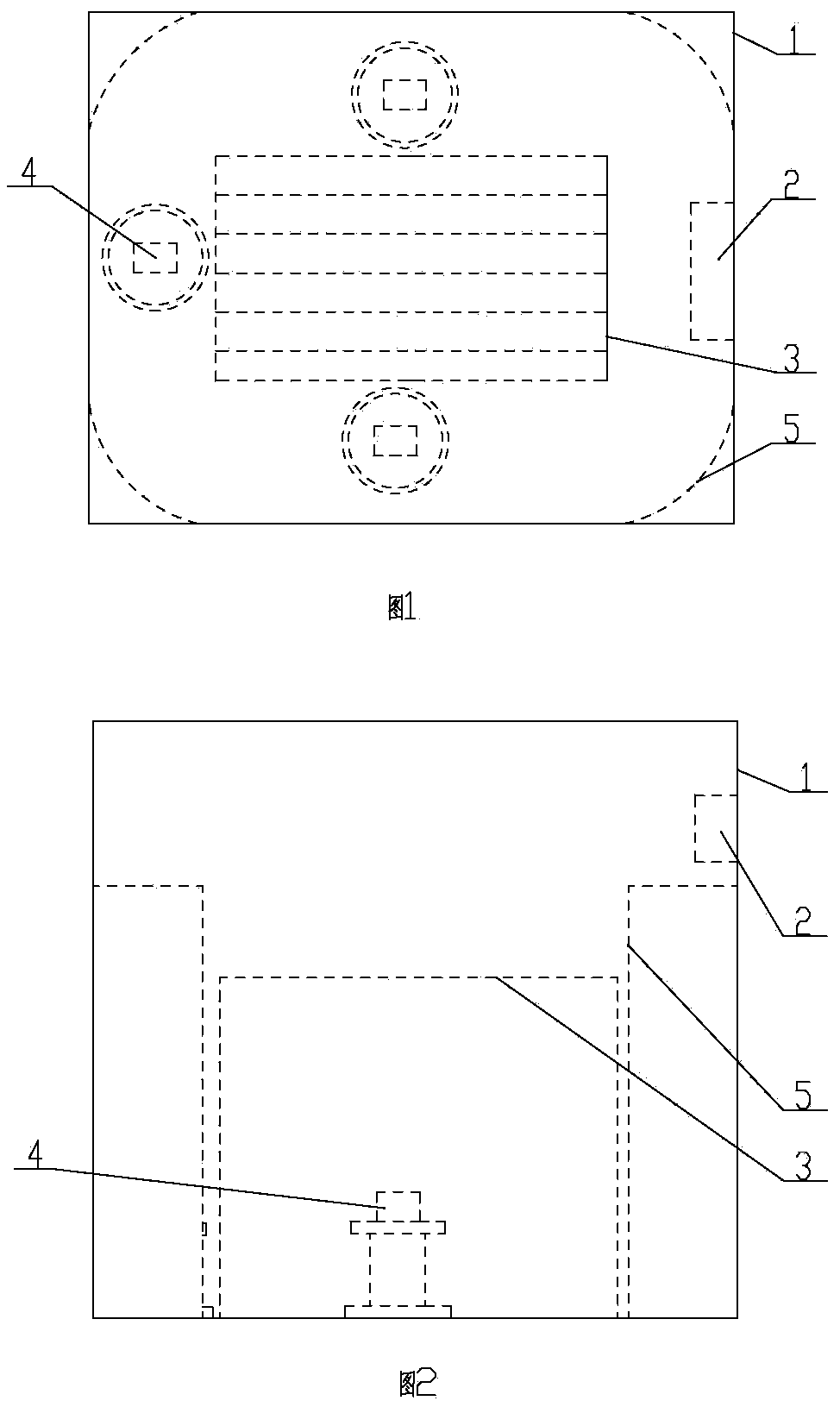

[0023] Embodiment 3: as Figures 1 to 2 As shown, in the fifth step, the delicious beef strips are air-dried in the vortex-type air-drying chamber. The vortex-type air-drying chamber includes an air-drying chamber 1 with a door on the side of the air-drying chamber 1, and a door is fixed in the air-drying chamber 1 above the door. The hot air curtain machine 2 corresponding up and down is arranged with not less than one air-drying frame 3 in the center of the air-drying chamber 1, and an exhaust fan is fixed on the side of the air-drying chamber 1, and the front, rear and left sides of the air-drying frame 3 Axial fans 4 are installed in the air-drying chamber 1, and the rotating speed of the axial-flow fans 4 is 4000 rpm to 6000 rpm. The corners of the air-drying chamber 1 are fixed with arc-shaped swirl wind plates 5. Hot air curtain machine 2 and axial flow blower 4 are existing known technologies, and the wind in the air-drying chamber 1 can form the vortex type wind to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com