Pneumatic device for measuring internal diameter and external diameter of thin-wall bearing ring

A thin-walled bearing and pneumatic measurement technology, which is applied in the field of testing, can solve problems that affect the surface quality of the tested part, easily produce marks on the tested surface, and cannot be effectively measured, so as to achieve small error, small measurement force and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

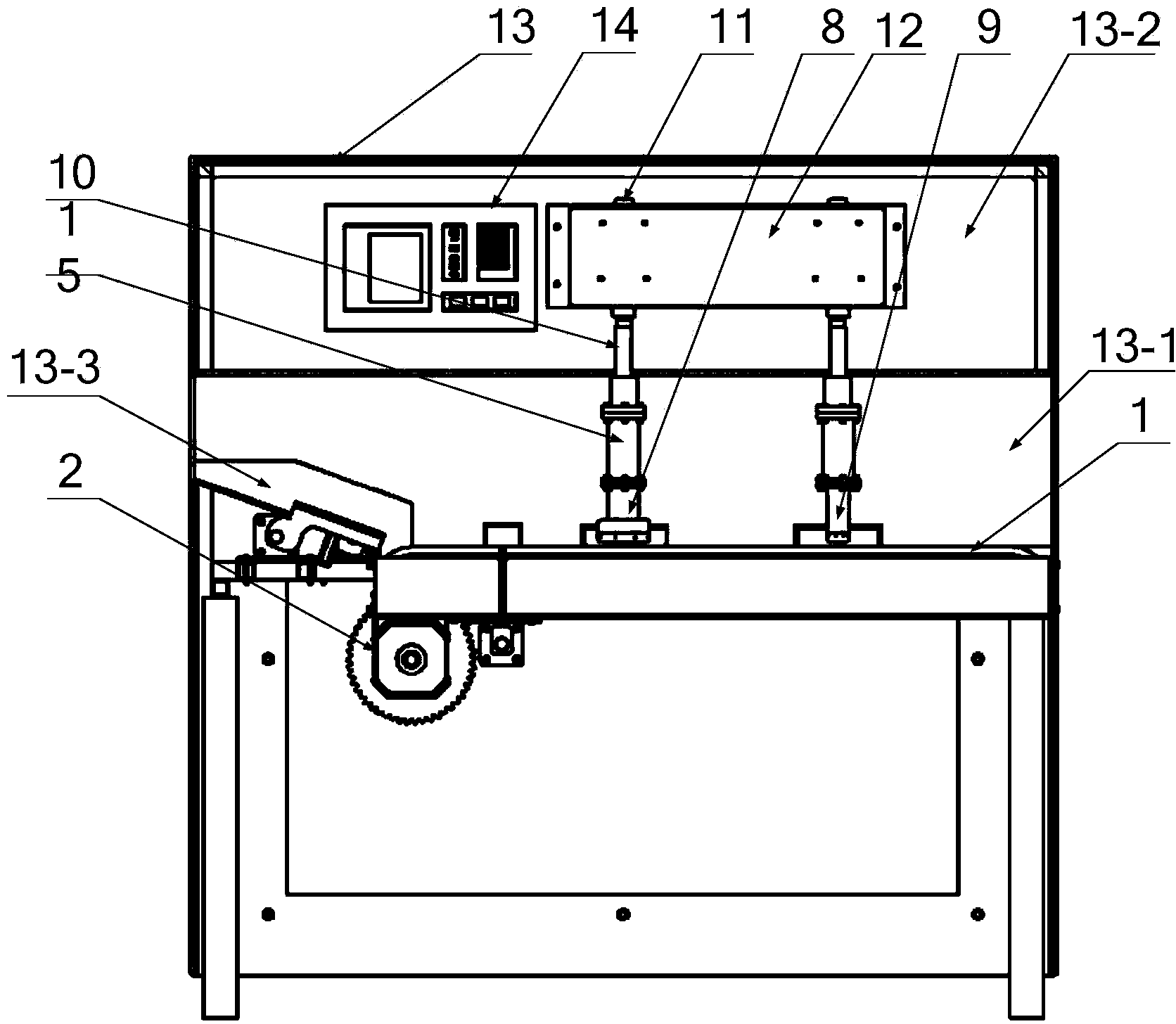

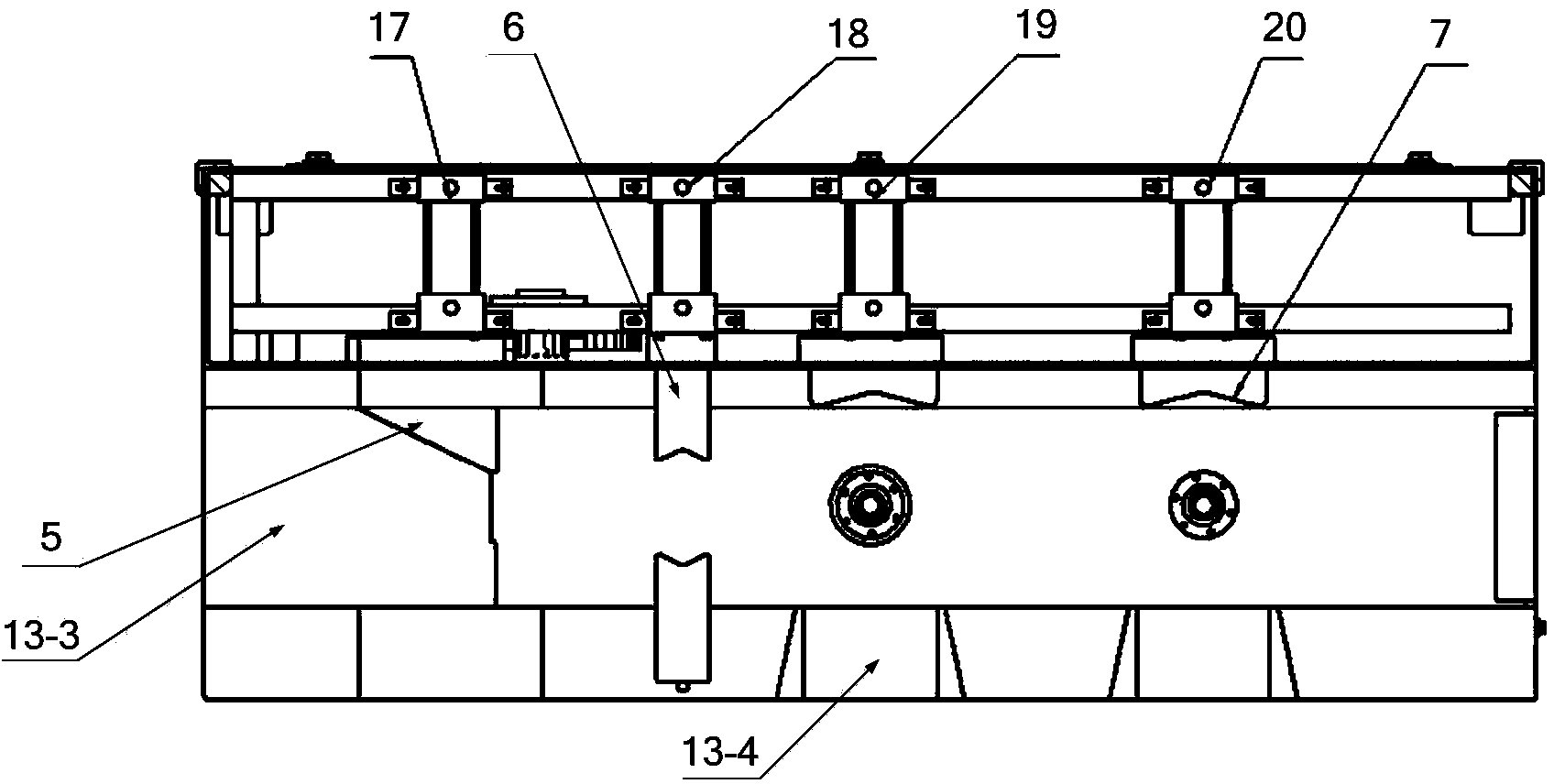

[0025] Such as figure 1 and 2 As shown, a pneumatic measuring device for inner and outer diameters of thin-walled bearing rings includes a conveyor belt 1, a stepping motor 2, a baffle plate 5, a centering fixture 6, a screening push plate 7, an outer diameter measuring head 8, an inner diameter measuring head 9, Control panel 14 , measuring drive, valve cylinder 17 , centering cylinder 18 , first screening cylinder 19 and second screening cylinder 20 .

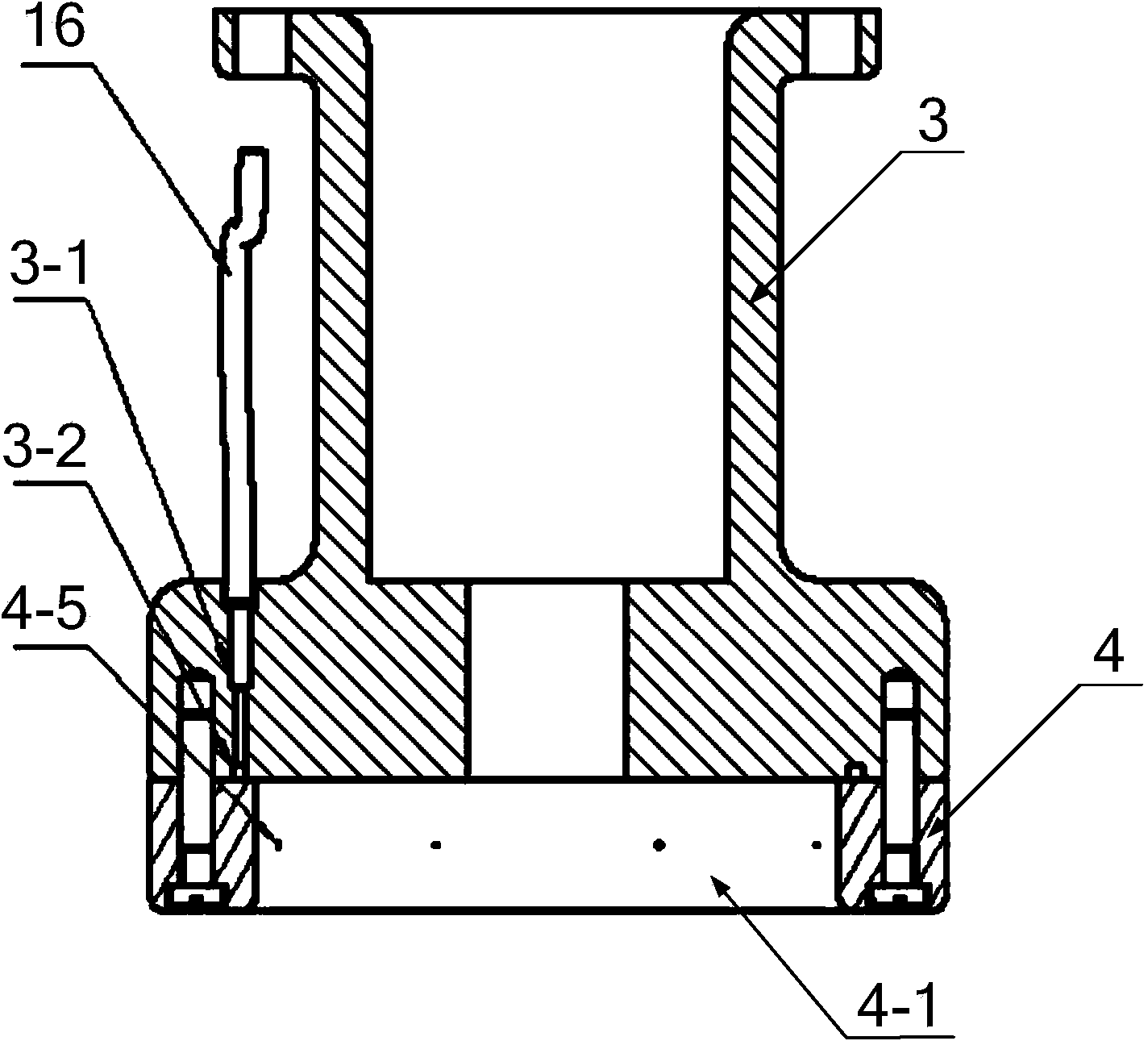

[0026] A detection chamber 13-1 is provided in the middle of the detection box 13, and a motor installation chamber 13-2 is provided on the top; a slant plate 13-3 is fixed at one end of the detection chamber 13-1, and two collection slots 13-4 are provided on one side ; Two valve cylinders 17 are respectively arranged on both sides of the detection chamber 13-1, and the piston rod of each valve cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com