Four-edge thread forming tap

A technology of extruding taps and extruding cones, which is applied in the field of taps, can solve the problems of workpiece scrapping, etc., and achieve the effects of increasing strength, increasing processing range, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

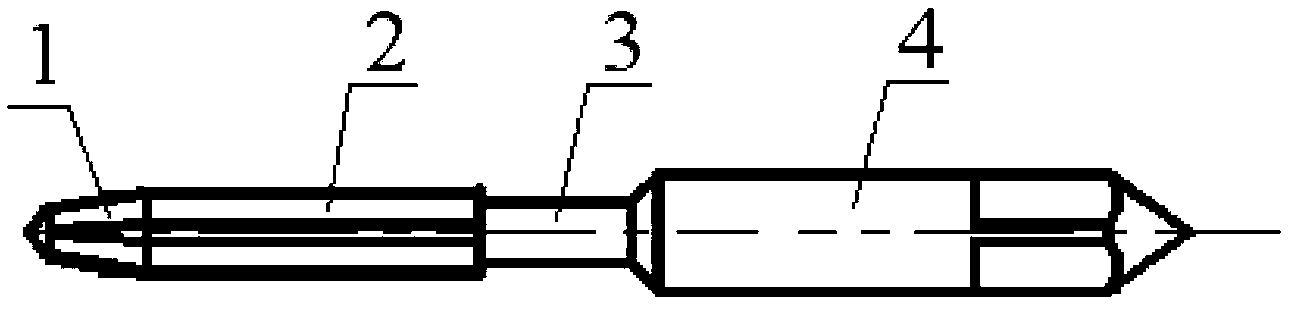

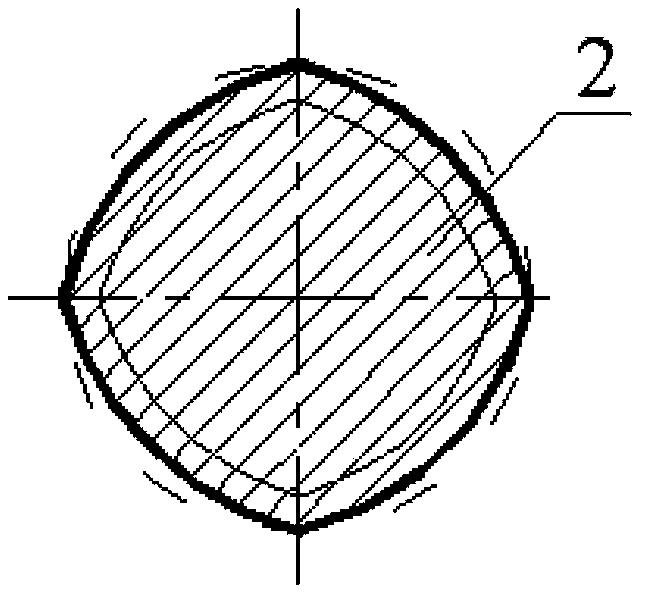

[0020] A four-sided extruded tap, its structure is as follows figure 1 As shown, it includes extrusion cone part 1, calibration part 2 and handle 4. Calibration part 2 is integrally arranged at the rear end of extrusion cone part 1. Extrusion cone part 1 and calibration part 2 are straight square-edge structures, such as figure 2 As shown, the straight square edge structure adopted can not only increase the strength of the tap, but also ensure the accuracy of the pitch diameter of the tap. The length of the extruded cone part 1 is 4-5 times of the pitch, which can not only ensure the roughness of the threaded hole to be processed, but also satisfy the processing of the blind threaded hole. The outside of the calibration part 2 is provided with external threads. The rear end of the calibration part 2 is connected to the handle 4 through a thin neck part 3 . The thin neck part 3 is equivalent to an empty sipe, which is suitable for deep hole thread processing, and can prevent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com