Ethylene oligomerization method

A technology of ethylene oligomerization and ethylene, which is applied in the direction of addition of unsaturated hydrocarbons to hydrocarbons, organic chemistry, etc., can solve the problems of high polymers hanging on the wall that are difficult to clean up and affect production efficiency, so as to facilitate processing, improve production efficiency, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

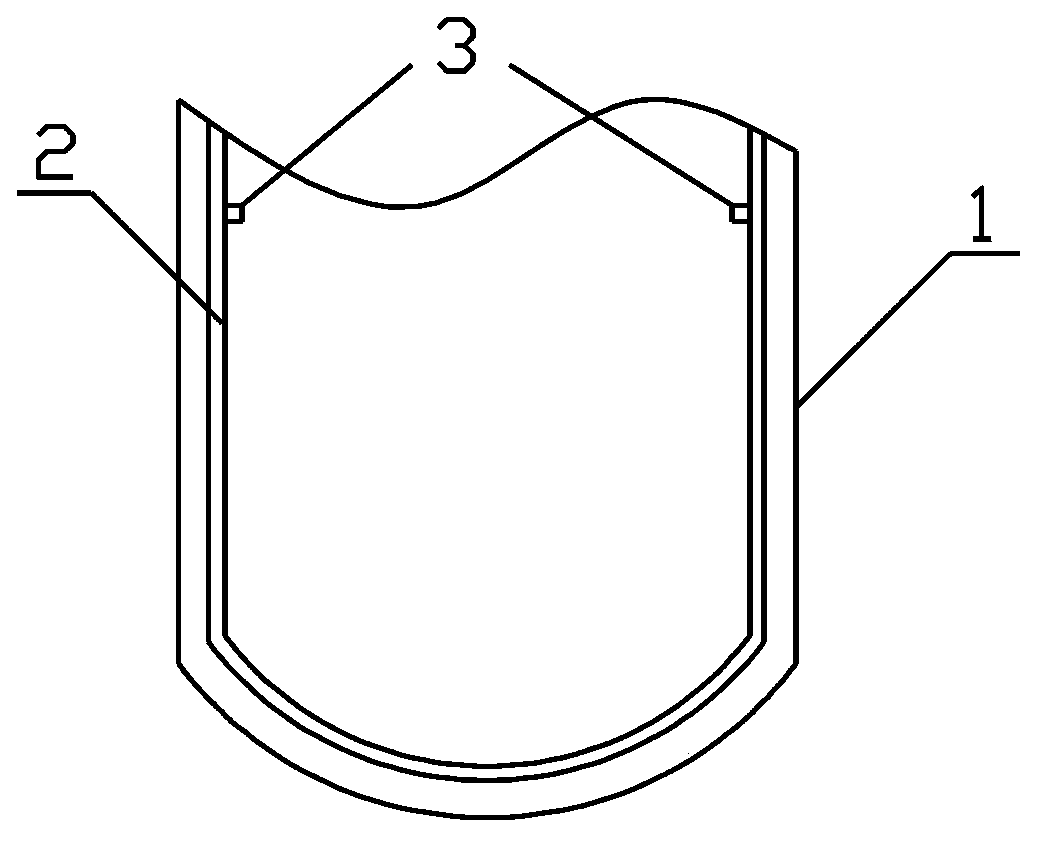

[0019] Such as figure 1 As shown, the inner kettle body 2 is placed in the reaction kettle 1 at first. The reaction solvent toluene was placed in the inner kettle body 2, the reaction temperature was set at 30° C., and the reaction pressure was 3.0 MPa. When the solvent is preheated to the set temperature, the mass space velocity is 30 ~ 60g h -1 Feed the reaction raw material ethylene to carry out the reaction. After reacting for 30 minutes, stop heating to terminate the reaction, open the reactor, and tilt the reactor so as to discharge the reaction solution.

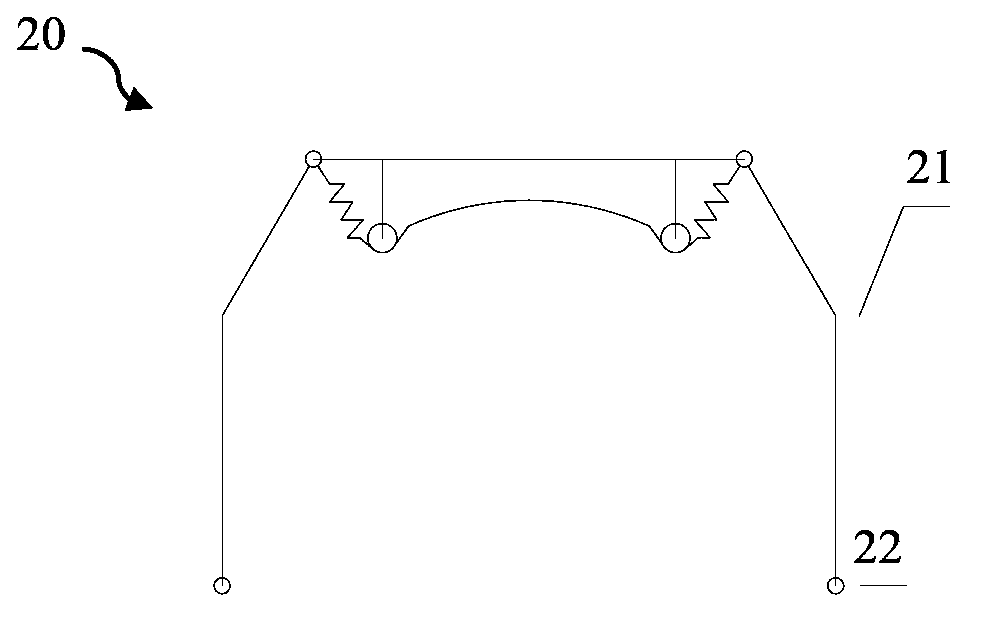

[0020] Reload the reaction solvent in the inner kettle body 2, then repeat the above steps to carry out the second reaction. When carrying out to the 5th reaction, it was found that the polymer wall on the inner wall of the inner still body 2 was thicker, and at this time, the extractor 20 ( figure 2 ) Take out the inner kettle body. Such as figure 2 As shown, the extractor 20 includes at least two grasping ro...

Embodiment 2

[0024] The specific operation steps are roughly the same as in Example 1, except that the reaction pressure is 5.0 MPa; when the third reaction is carried out, it is found that the polymer wall on the inner wall of the inner kettle body 2 is thicker, and the inner wall is replaced at this time. Kettle body; wash with high-pressure water (operating pressure 70MPa) to make the polymer fall off, collect the fallen polymer, put it in a drying oven and heat it up to 100°C to dry and weigh it. The weight of the polymer is the total weight of the reaction solution 3%, the molecular weight distribution of the polymer is 3500-6000000.

Embodiment 3

[0026] The specific operation steps are roughly the same as in Example 1, except that the reaction solvent is heptane; when the third reaction is carried out, it is found that the polymer wall on the inner wall of the inner still body 2 is thicker, and the inner still is replaced at this time body; wash with high-pressure water (operating pressure 55MPa) to make the polymer fall off, collect the fallen polymer, put it in a drying oven and heat it up to 100°C to dry and weigh it. The weight of the polymer is the total weight of the reaction solution. 3.5%, the molecular weight of the polymer is 2500-6000000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com