Bagasse-fired boiler

A bagasse and boiler technology, applied in steam boilers, combustion methods, lighting and heating equipment, etc., can solve the problems of unfavorable slag discharge, easy blockage of grate surface tuyere, low melting point of ash and slag, and prevent economizers Effects of boiling, improving resource utilization, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

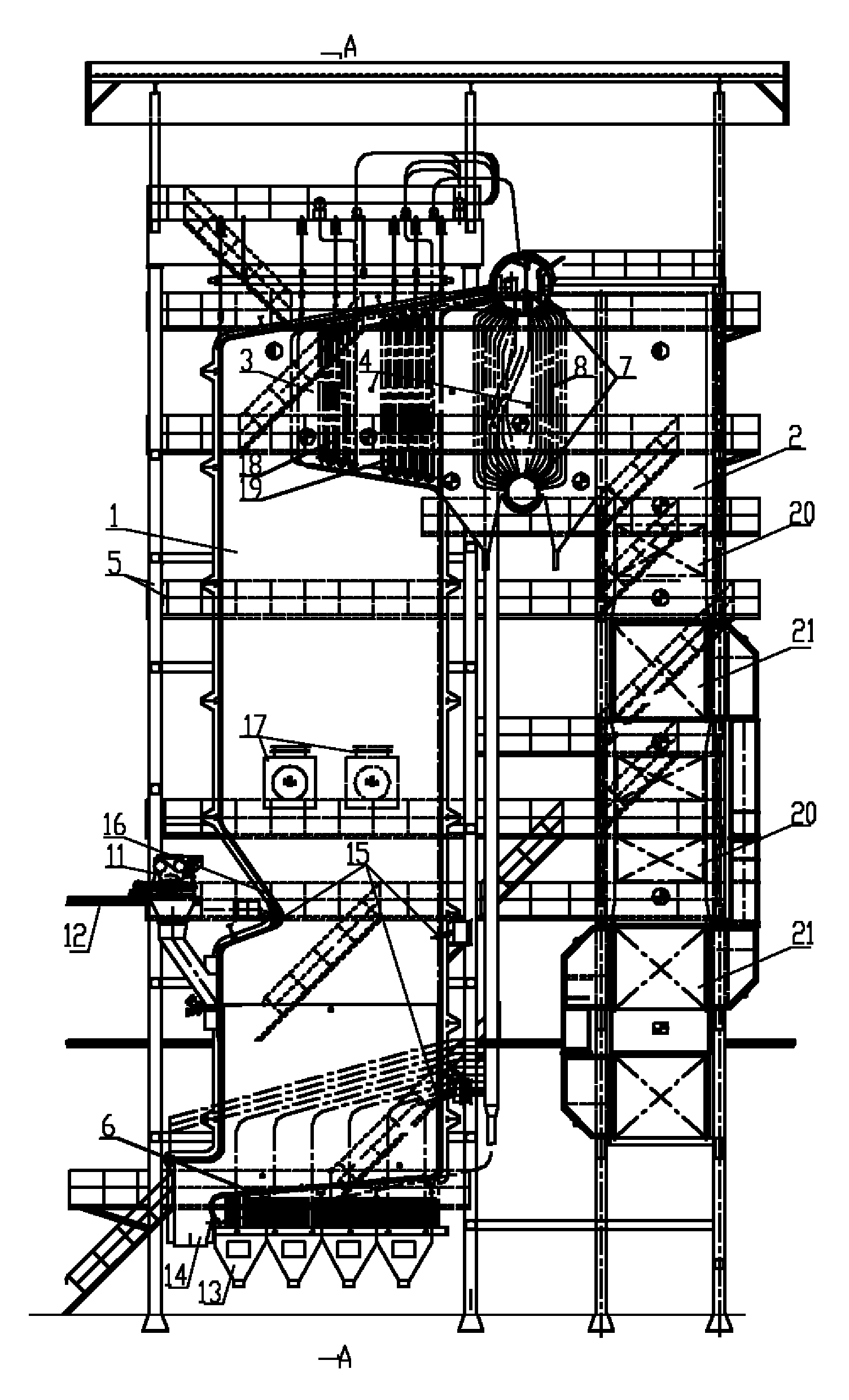

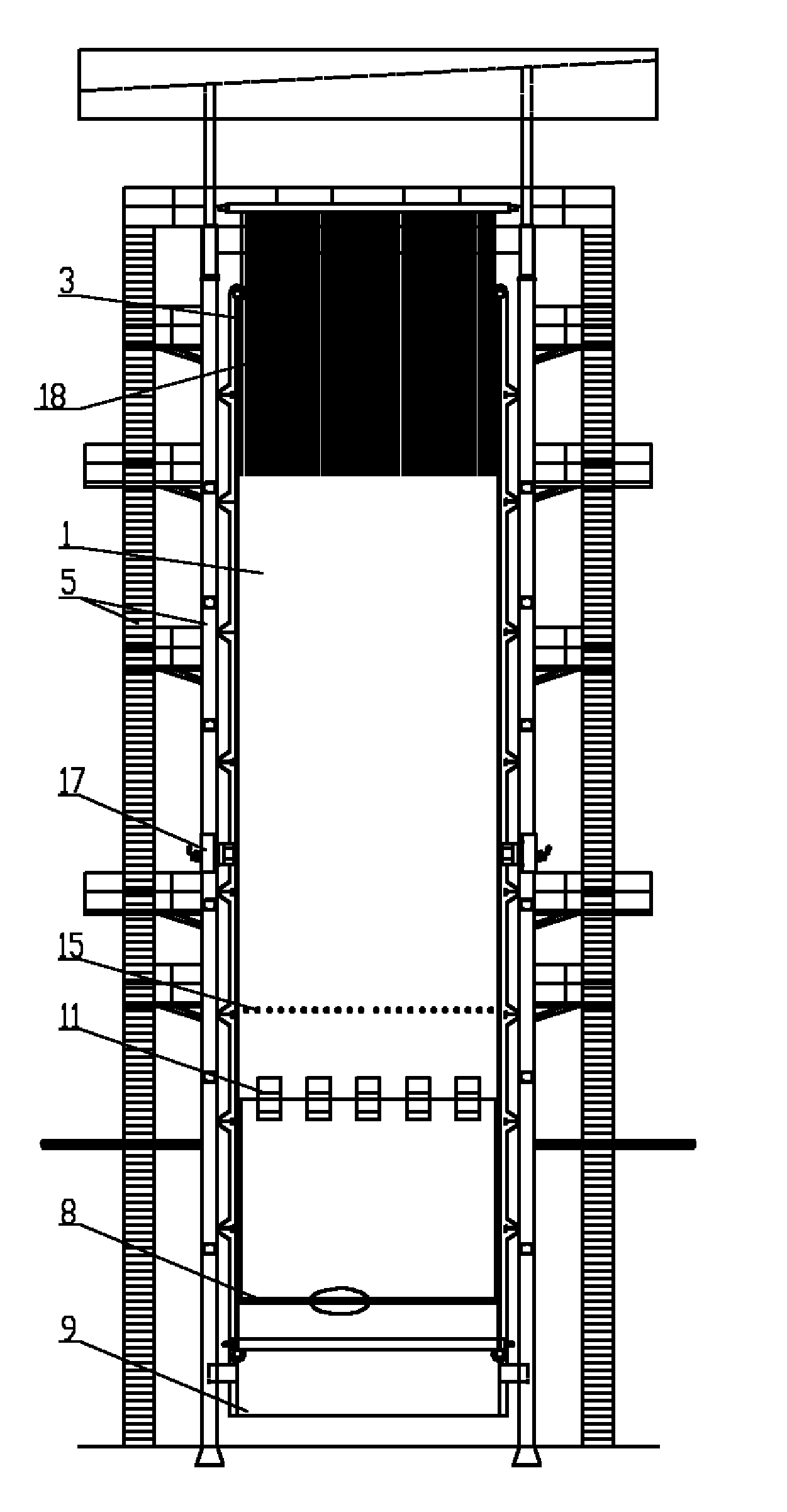

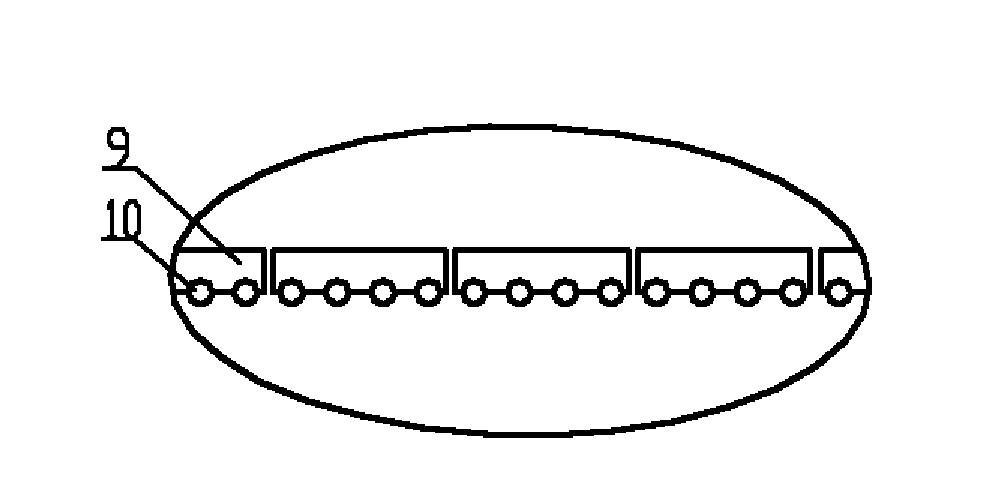

[0023] See figure 1 , figure 2 , image 3 , which includes furnace 1, feeding device, fire grate, drum, tail flue 2, superheater chamber 3, soot blower 4, boiler steel frame 5, the fire grate is arranged at the lower part of furnace 1, and the feeding device is arranged at the furnace The front part of 1, the furnace 1, the superheater chamber 2, the drum, and the tail flue 2 are connected in sequence. The grate is specifically a water-cooled fixed grate 6, and the drum is specifically a double drum 7. The tube bundle 8 is connected, and a feeding device is arranged obliquely above the water-cooled fixed grate 6; the water-cooled fixed grate 6 specifically includes a fixed grate 9 and a water-cooled tube 10, and the water-cooled tube 10 is arranged at the lower part of the fixed grate 9, and the fixed grate 9. The water-cooled pipes 10 are connected together; the side of the fixed fire grate 9 close to the boiler steel frame 5 is inclined downward; the feeding device is spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com